Understanding LED PCB Base Plates

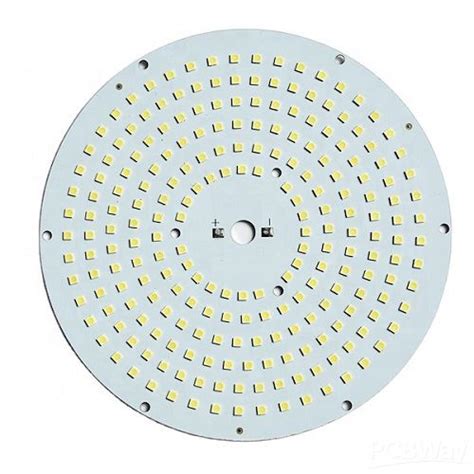

What is an LED PCB Base Plate?

An LED PCB base plate is the foundation upon which the LED components and circuitry are mounted. It serves as a support structure and helps dissipate heat generated by the LEDs, ensuring proper thermal management.

Types of LED PCB Base Plates

There are several types of LED PCB base plates available, each with its own unique properties and characteristics:

- Aluminum Base Plates

- Copper Base Plates

- Ceramic Base Plates

- FR-4 Base Plates

Aluminum Base Plates

Advantages of Aluminum Base Plates

Aluminum base plates offer several advantages for LED PCBs:

- Excellent thermal conductivity

- Lightweight and durable

- Cost-effective solution

- Easy to machine and customize

Disadvantages of Aluminum Base Plates

Despite their benefits, aluminum base plates also have some drawbacks:

- Lower electrical conductivity compared to copper

- Susceptible to corrosion in harsh environments

- Thermal expansion mismatch with PCB materials

Applications of Aluminum Base Plates

Aluminum base plates are suitable for a wide range of LED applications, including:

- Indoor lighting fixtures

- Outdoor signage and displays

- Automotive lighting

Copper Base Plates

Advantages of Copper Base Plates

Copper base plates provide several advantages for LED PCBs:

- Superior thermal conductivity

- Excellent electrical conductivity

- High resistance to corrosion

- Better thermal expansion matching with PCB materials

Disadvantages of Copper Base Plates

Copper base plates also have some drawbacks to consider:

- Higher cost compared to aluminum

- Heavier weight

- More difficult to machine and customize

Applications of Copper Base Plates

Copper base plates are ideal for high-performance LED applications, such as:

- High-power LED lighting

- Industrial lighting fixtures

- Medical equipment

Ceramic Base Plates

Advantages of Ceramic Base Plates

Ceramic base plates offer unique benefits for LED PCBs:

- Excellent thermal stability

- High electrical insulation

- Resistance to corrosion and chemicals

- Low thermal expansion

Disadvantages of Ceramic Base Plates

Ceramic base plates also have some limitations:

- Brittle and prone to cracking

- Higher manufacturing costs

- Limited design flexibility

Applications of Ceramic Base Plates

Ceramic base plates are suitable for specialized LED applications, such as:

- High-temperature environments

- Hazardous locations

- Aerospace and military applications

FR-4 Base Plates

Advantages of FR-4 Base Plates

FR-4 base plates provide several advantages for LED PCBs:

- Low cost and widely available

- Good electrical insulation

- Ease of manufacturing

- Compatibility with standard PCB processes

Disadvantages of FR-4 Base Plates

FR-4 base plates also have some drawbacks:

- Poor thermal conductivity

- Limited heat dissipation capabilities

- Not suitable for high-power LED applications

Applications of FR-4 Base Plates

FR-4 base plates are suitable for low-power LED applications, such as:

- Indicators and status lights

- Decorative lighting

- Low-power signage

Comparison Table

| Base Plate Material | Thermal Conductivity | Electrical Conductivity | Weight | Cost |

|---|---|---|---|---|

| Aluminum | High | Moderate | Low | Low |

| Copper | Very High | High | High | High |

| Ceramic | Moderate | Low | Low | High |

| FR-4 | Low | Low | Low | Low |

Frequently Asked Questions (FAQ)

-

Q: What is the best LED PCB base plate material for high-power applications?

A: For high-power LED applications, copper base plates are the best choice due to their superior thermal conductivity and excellent electrical conductivity. They can effectively dissipate heat and ensure optimal performance of the LEDs. -

Q: Can aluminum base plates be used in outdoor LED applications?

A: Yes, aluminum base plates can be used in outdoor LED applications, but they may be susceptible to corrosion in harsh environments. To mitigate this issue, protective coatings or anodization can be applied to the aluminum surface. -

Q: Are ceramic base plates suitable for flexible LED PCB designs?

A: No, ceramic base plates are not suitable for flexible LED PCB designs due to their brittle nature and limited design flexibility. They are better suited for rigid and specialized applications where thermal stability and corrosion resistance are critical. -

Q: Can FR-4 base plates be used for high-temperature LED applications?

A: No, FR-4 base plates are not recommended for high-temperature LED applications due to their poor thermal conductivity and limited heat dissipation capabilities. They are better suited for low-power and non-critical LED applications. -

Q: How do I choose the right LED PCB base plate for my application?

A: When choosing an LED PCB base plate, consider factors such as thermal management requirements, electrical conductivity, environmental conditions, cost, and design flexibility. Evaluate the advantages and disadvantages of each base plate material and select the one that best meets your specific application needs.

Conclusion

Choosing the right LED PCB base plate is essential for ensuring optimal performance, reliability, and longevity of LED systems. Aluminum, copper, ceramic, and FR-4 base plates each have their own advantages and disadvantages, making them suitable for different applications.

By understanding the properties and characteristics of each base plate material, designers and manufacturers can make informed decisions when selecting the most appropriate option for their specific LED PCB requirements.

Ultimately, the choice of LED PCB base plate depends on factors such as thermal management, electrical conductivity, environmental conditions, cost, and design flexibility. By carefully considering these factors and evaluating the trade-offs, engineers can design and manufacture LED PCBs that deliver exceptional performance and long-term reliability.

No responses yet