About EMS

We solve technology challenges for a sustainable world, EMS is a global, advanced electronics technologies for performance critical applications in specialised markets

From design to mass-production, we understand flexibility and customer relationship are as important as advanced engineering skills. Placing continuous improvement and excellence at the heart of our processes, we will support your project from any of our facilities the same way: seamlessly.

key features

Rapid Prototyping

As part of our NPI process, rapid prototyping offers companies the opportunity to remain competitive by introducing new products to the market faster. Rapid prototyping can reduce the time between iterations and allow engineers to discover innovative ways of solving any engineering problems.

SMT Assembly

BGA\QFN Package SMT Assembly

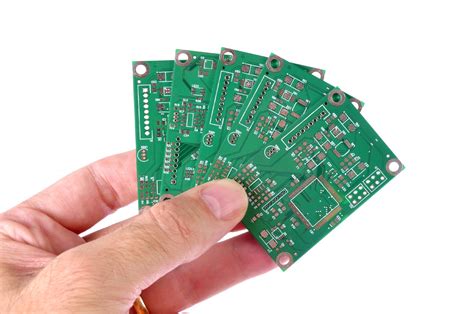

PCB Manufacturing

RF, HDI Rigid Flex Board Manufacturing

Components Sourcing

Electronic Parts Full or partial procurement

As Your Partner, We Get You There

Our team of global engineering experts are here to guide and support you through new product introductions and complex designs. With decades of expreience, you can trust we have the knowlege and technology to deliver your quality product to market quickly and effectively.

HOW WE WORK

At EMS, we help our customers Innovate, Scale, and Repeat. We make the transition between design and manufacturing seamless. And we work with you to extend the lifetime of products out in the marketplace whilst supporting you with the next iteration. It’s a continuous cycle of improvement.

INNOVATE

You are an inventor. You have the idea, the concept, the vision of what you want to create. So, together, we Innovate. Through our design and development and NPI processes, we take your idea and make it a reality by turning it into a market leading product.

SCALE

Whatever product or market, EMS is a truly global company with sites across Europe and Asia that use the latest technology. We seamlessly transition from prototyping to volume manufacturing so you can Scale and meet the needs of your market.

REPEAT

Demand for your product is strong but you know it’s only a matter of time before the competition start to try and catch up. You’re not looking to stand still, you’re a market leader, and that’s where the Repeat stage of the EMS process kicks in.

Is Your Product Ready for Manufacturing?

It is essential to design for manufacturability before the actual production process. As a result, you will procure efficient processes and a reliable product outcome. Exceptional engineering design practices start with careful consideration of the product requirements up-front to reduce or eliminate the delays and redesign costs.

There are always variables to consider, but with DFx (design for excellence) you have confidence that the products are reliable, testable, and have a faster time to market. All these variables equate to happier and satisfied customers.

Portfolio

Manufacturing Solutions Journey

Your product and quality teams are more dispersed than ever. EMS make it easy for everyone to collaborate around the latest information anytime and anywhere.

Explore Our Blog

WHAT IS HIGH-SPEED DESIGN?

The Need for High-Speed Design The demand for high-speed electronic systems has been driven by the ever-increasing need for[…]

Eagle PCB Download-The Comprehensive Guide and Installation

What is Eagle PCB? Eagle PCB is a powerful and popular software tool used for designing printed circuit boards[…]

pad stack design and fine pitch components part 2

Introduction to Pad Stack Design for Fine Pitch Components In the world of electronics manufacturing, pad stack design plays[…]

pad stack design and fabrication process part 1

Introduction to Pad stack design Pad stack design is a critical aspect of printed circuit board (PCB) design, as[…]

Contact us

Please reach out if you have questions about program eligibility, application or referral processes, shop capabilities, how to make a gift, or other ways to get involved. Call or submit the contact form below.