What is a PCB Prototype?

A PCB prototype is a physical representation of the designed circuit board. It is created to test the functionality, reliability, and compatibility of the circuit design before mass production. PCB Prototypes are essential in the product development process as they allow designers to identify and fix any issues early on, saving time and money in the long run.

Types of PCB Prototypes

There are several types of PCB prototypes, each serving a specific purpose in the product development process. Here are the most common types of PCB prototypes:

-

Breadboard Prototype: A breadboard is a simple, reusable platform used for creating temporary prototypes. It allows designers to quickly test and modify their circuit designs without soldering.

-

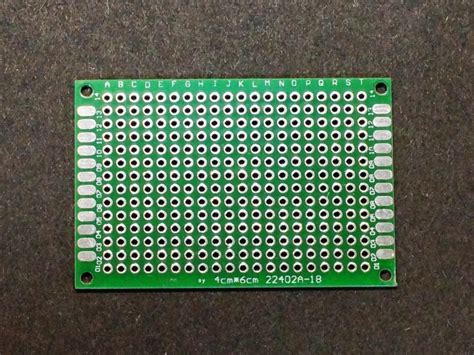

Stripboard Prototype: A stripboard is a pre-made PCB with copper strips and pre-drilled holes. Designers can cut the strips and solder components to create a permanent prototype.

-

PCB Prototype: A PCB prototype is a custom-made, fully functional circuit board that closely resembles the final product. It is created using the same materials and manufacturing processes as the final PCB.

Benefits of PCB Prototyping

PCB prototyping offers several benefits in the product development process. Here are some of the key advantages:

-

Design Validation: PCB prototypes allow designers to validate their circuit designs and ensure that they function as intended. This helps identify any design flaws early on, reducing the risk of costly mistakes in the final product.

-

Functionality Testing: With a PCB prototype, designers can test the functionality of their circuit under real-world conditions. This helps identify any performance issues or compatibility problems before mass production.

-

Iterative Refinement: PCB prototyping allows for iterative refinement of the circuit design. Designers can make modifications and improvements based on the prototype’s performance, ensuring that the final product meets all requirements.

-

Cost Savings: By identifying and fixing design issues early on, PCB prototyping helps avoid costly mistakes and rework in the mass production stage. This ultimately leads to significant cost savings in the overall product development process.

Choosing the Best PCB Prototype Service

When it comes to creating a PCB prototype, choosing the right service provider is crucial. A reliable PCB prototype service should offer high-quality manufacturing, quick turnaround times, and excellent customer support. Here are some factors to consider when selecting a PCB prototype service:

Manufacturing Capabilities

A good PCB prototype service should have advanced manufacturing capabilities to handle a wide range of PCB designs and requirements. Look for a service provider that offers:

- Multi-layer PCB fabrication

- High-density interconnect (HDI) PCBs

- Flexible and rigid-flex PCBs

- Various surface finishes (e.g., HASL, ENIG, OSP)

- Impedance control

- Blind and buried vias

Turnaround Time

In the fast-paced world of electronics, time to market is critical. Choose a PCB prototype service that offers quick turnaround times without compromising on quality. Some service providers offer expedited manufacturing options for urgent projects.

Quality Control

Quality is paramount when it comes to PCB prototypes. A reliable PCB prototype service should have strict quality control measures in place to ensure that every prototype meets the highest standards. Look for a service provider that follows industry standards such as IPC Class 2 or 3 and has a proven track record of delivering high-quality PCBs.

Customer Support

Good customer support is essential when working with a PCB prototype service. Look for a service provider that offers responsive and knowledgeable customer support to guide you through the prototyping process. They should be able to answer your questions, provide design feedback, and assist with any issues that may arise.

Pricing

Pricing is another important factor to consider when choosing a PCB prototype service. While cost is important, it should not be the sole deciding factor. Look for a service provider that offers competitive pricing without compromising on quality or service.

The PCB Prototype Process

Once you have chosen a PCB prototype service, the next step is to understand the prototyping process. Here is a general overview of the PCB prototype process:

-

Design Submission: The first step is to submit your PCB design files to the service provider. Most providers accept standard file formats such as Gerber, ODB++, or Eagle.

-

Design Review: The service provider will review your design files to ensure that they meet their manufacturing capabilities and design guidelines. They may provide feedback or suggestions for improvement.

-

Prototype Manufacturing: Once the design is finalized, the service provider will begin manufacturing the PCB prototype. This process typically involves the following steps:

- PCB fabrication

- Component sourcing and procurement

- PCB Assembly

-

Quality control and testing

-

Delivery: After the PCB prototype is manufactured and tested, the service provider will package and ship it to you. Some providers offer tracking information to keep you updated on the status of your order.

FAQs

1. How long does it take to manufacture a PCB prototype?

The manufacturing time for a PCB prototype depends on various factors such as the complexity of the design, the chosen service provider, and the selected manufacturing options. Typically, PCB prototypes can be manufactured within 5-15 business days. Some service providers offer expedited manufacturing options for faster turnaround times.

2. How much does a PCB prototype cost?

The cost of a PCB prototype varies based on factors such as the PCB size, layer count, quantity, and selected manufacturing options. Some service providers offer instant online quoting tools that allow you to estimate the cost of your PCB prototype based on your specific requirements.

3. What files do I need to submit for PCB prototyping?

To begin the PCB prototyping process, you typically need to submit your PCB design files in a standard format such as Gerber, ODB++, or Eagle. These files should include information such as the PCB layout, layer stackup, drill data, and bill of materials (BOM).

4. Can I request changes to my PCB prototype after submitting my design?

Most PCB prototype services allow you to request changes to your design before the manufacturing process begins. However, once the manufacturing process has started, changes may not be possible or may incur additional costs. It is important to thoroughly review and finalize your design before submitting it for prototyping.

5. What happens if my PCB prototype doesn’t function as expected?

If your PCB prototype does not function as expected, the first step is to troubleshoot the issue. Many PCB prototype services offer support and guidance to help identify and resolve any problems. If the issue is found to be a manufacturing defect, reputable service providers will typically offer a replacement or refund.

Conclusion

PCB prototyping is a critical step in the product development process that ensures the functionality, reliability, and compatibility of your circuit design. Choosing the best PCB prototype service is essential for the success of your project. Consider factors such as manufacturing capabilities, turnaround time, quality control, customer support, and pricing when selecting a service provider.

By partnering with a reliable PCB prototype service, you can streamline your product development process, reduce costs, and bring your electronic products to market faster. With the right prototyping partner, you can focus on innovation and growth while leaving the manufacturing to the experts.

| Factor | Importance |

|---|---|

| Manufacturing Capabilities | Ensures that the service provider can handle your specific PCB design requirements. |

| Turnaround Time | Quick turnaround times are essential for timely product development and faster time to market. |

| Quality Control | Strict quality control measures ensure that your PCB prototypes meet the highest standards and function as intended. |

| Customer Support | Responsive and knowledgeable customer support guides you through the prototyping process and assists with any issues that may arise. |

| Pricing | Competitive pricing without compromising on quality or service is important for budget management. |

Remember, a successful PCB prototype is the foundation of a successful electronic product. By choosing the best PCB prototype service and following a structured prototyping process, you can bring your innovative ideas to life and stay ahead in the competitive electronics industry.

No responses yet