What are SMD LEDs?

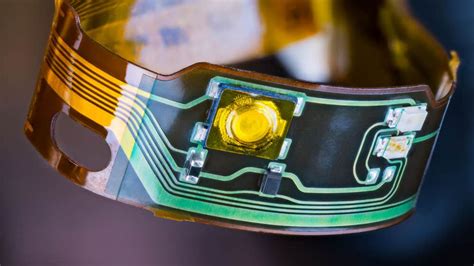

SMD LEDs, or Surface Mounted Device Light Emitting Diodes, are a type of LED package that is designed to be mounted directly onto the surface of a printed circuit board (PCB). They are the most common type of LED used in electronics today, thanks to their small size, low power consumption, and ease of installation.

Advantages of SMD LEDs

-

Compact size: SMD LEDs are incredibly small, allowing for high-density packaging on PCBs. This makes them ideal for applications where space is limited, such as in mobile devices, wearables, and miniature displays.

-

Low power consumption: SMD LEDs are highly efficient, requiring less power to operate compared to traditional through-hole LEDs. This makes them suitable for battery-powered devices and energy-conscious applications.

-

Easy to install: SMD LEDs are designed for surface mounting, which means they can be easily placed and soldered onto PCBs using automated pick-and-place machines. This streamlines the manufacturing process and reduces assembly costs.

-

Wide variety of sizes and colors: SMD LEDs come in a range of sizes, from tiny 0402 packages (measuring just 0.4mm x 0.2mm) to larger 5630 packages (5.6mm x 3.0mm). They are also available in a wide spectrum of colors, including red, green, blue, white, and various color temperatures of white.

Disadvantages of SMD LEDs

-

Limited power output: Due to their small size, individual SMD LEDs have a limited power output compared to larger LED packages. This means that multiple SMD LEDs may be required to achieve the desired brightness level, which can increase the overall cost and complexity of the PCB design.

-

Sensitivity to heat: SMD LEDs are sensitive to heat, and their performance can degrade if they are exposed to high temperatures for extended periods. Proper thermal management, such as the use of heat sinks and adequate ventilation, is crucial to ensure the longevity and reliability of SMD LEDs.

-

Potential for color inconsistency: Due to variations in the manufacturing process, SMD LEDs from different batches or suppliers may exhibit slight differences in color and brightness. This can be problematic in applications where color consistency is critical, such as in high-end displays or lighting fixtures.

What are COB LEDs?

COB LEDs, or Chip on Board Light Emitting Diodes, are a type of LED package where multiple LED chips are mounted directly onto a substrate, such as a PCB or ceramic board, and then encapsulated with a layer of phosphor or silicone. This design allows for a higher density of LEDs in a single package, resulting in increased brightness and improved color consistency compared to individual SMD LEDs.

Advantages of COB LEDs

-

High brightness: COB LEDs can achieve much higher brightness levels than SMD LEDs, thanks to the high density of LED chips in a single package. This makes them suitable for applications that require intense illumination, such as in automotive headlights, floodlights, and high-bay lighting.

-

Improved color consistency: Because the LED chips in a COB package are mounted closely together and encapsulated under a single layer of phosphor or silicone, they tend to exhibit better color consistency compared to individual SMD LEDs. This is particularly important in applications where color uniformity is crucial, such as in professional lighting or high-end displays.

-

Simplified thermal management: COB LEDs have a larger surface area in contact with the substrate, which allows for better heat dissipation compared to SMD LEDs. This simplifies the thermal management requirements and can lead to improved reliability and longer lifespan of the LEDs.

-

Reduced assembly complexity: Since multiple LED chips are integrated into a single package, COB LEDs can reduce the number of components required on a PCB, simplifying the assembly process and potentially reducing manufacturing costs.

Disadvantages of COB LEDs

-

Limited design flexibility: COB LEDs are typically larger than SMD LEDs and have a fixed array of LED chips, which can limit the design flexibility for PCB layouts. This may be a concern in applications where space is constrained or where a specific LED arrangement is required.

-

Higher initial cost: Due to their more complex manufacturing process and higher component density, COB LEDs tend to have a higher initial cost compared to SMD LEDs. However, this cost difference may be offset by the reduced assembly complexity and improved performance in certain applications.

-

Increased driver complexity: COB LEDs often require more sophisticated driver circuits to ensure proper current distribution and control across the multiple LED chips in the package. This can increase the overall complexity and cost of the PCB design.

What are DOB LEDs?

DOB LEDs, or Die on Board Light Emitting Diodes, are a relatively new type of LED package that combines the benefits of SMD and COB LEDs. In a DOB LED, individual LED dies are mounted directly onto a PCB substrate without any additional packaging. The dies are then covered with a layer of phosphor or silicone, similar to COB LEDs.

Advantages of DOB LEDs

-

Ultra-compact size: DOB LEDs are even smaller than SMD LEDs, as they eliminate the need for individual packaging around each LED die. This allows for extremely high-density packaging on PCBs, making them ideal for applications where space is at a premium, such as in micro-displays or miniature indicators.

-

Improved thermal performance: Since the LED dies are mounted directly onto the PCB substrate, DOB LEDs offer excellent thermal conductivity, allowing for efficient heat dissipation. This can lead to improved reliability and longer lifespan compared to SMD LEDs.

-

High design flexibility: DOB LEDs allow for greater design flexibility compared to COB LEDs, as the individual LED dies can be arranged in custom patterns or layouts to suit specific application requirements.

-

Cost-effective for high-volume production: While the initial setup costs for DOB LED manufacturing may be higher due to the specialized equipment and processes required, they can be cost-effective for high-volume production runs, as they minimize the number of components and assembly steps needed.

Disadvantages of DOB LEDs

-

Limited availability: As a relatively new technology, DOB LEDs are not as widely available as SMD or COB LEDs, which may limit their adoption in certain applications or markets.

-

Higher manufacturing complexity: The process of mounting individual LED dies directly onto a PCB substrate requires specialized equipment and expertise, which can increase the manufacturing complexity and initial setup costs compared to SMD LEDs.

-

Increased driver complexity: Similar to COB LEDs, DOB LEDs may require more sophisticated driver circuits to ensure proper current distribution and control across the multiple LED dies. This can increase the overall complexity and cost of the PCB design.

Comparison Table

| Feature | SMD LEDs | COB LEDs | DOB LEDs |

|---|---|---|---|

| Size | Small | Large | Ultra-compact |

| Brightness | Moderate | High | Moderate |

| Color Consistency | Moderate | High | High |

| Thermal Performance | Moderate | Good | Excellent |

| Design Flexibility | High | Limited | High |

| Assembly Complexity | Low | Moderate | High |

| Cost (Low Volume) | Low | High | High |

| Cost (High Volume) | Low | Moderate | Low |

FAQ

-

Q: Which type of LED is best suited for applications requiring high brightness?

A: COB LEDs are the best choice for applications that demand high brightness levels, such as automotive headlights, floodlights, and high-bay lighting. -

Q: Which LED type offers the greatest design flexibility for Custom PCB layouts?

A: SMD LEDs and DOB LEDs offer the highest design flexibility, as they allow for custom arrangements and layouts of individual LEDs or dies on the PCB substrate. -

Q: Which LED type is the most cost-effective for high-volume production?

A: DOB LEDs can be the most cost-effective option for high-volume production, as they minimize the number of components and assembly steps required. However, the initial setup costs may be higher compared to SMD LEDs. -

Q: Which LED type is best for applications where space is extremely limited?

A: DOB LEDs are the most compact option, making them ideal for applications with severe space constraints, such as micro-displays or miniature indicators. -

Q: Which LED type requires the most complex driver circuits?

A: Both COB LEDs and DOB LEDs may require more sophisticated driver circuits compared to SMD LEDs, due to the need for proper current distribution and control across multiple LED chips or dies.

Conclusion

When selecting the appropriate LED type for your PCB project, it is essential to consider factors such as size, brightness, color consistency, thermal performance, design flexibility, assembly complexity, and cost. SMD LEDs offer a compact size, low power consumption, and easy installation, making them suitable for a wide range of applications. COB LEDs excel in high-brightness applications and offer improved color consistency and simplified thermal management. DOB LEDs combine the benefits of SMD and COB LEDs, providing ultra-compact size, excellent thermal performance, and high design flexibility.

By understanding the unique characteristics, advantages, and disadvantages of each LED type, you can make an informed decision that best suits your specific application requirements. Whether you prioritize size, brightness, color consistency, or cost-effectiveness, there is an LED option available to meet your needs. As technology continues to advance, it is likely that new LED packaging solutions will emerge, offering even more possibilities for LED PCB design and manufacturing.

No responses yet