Introduction to Altium365 and Version Control

Altium365 is a cloud-based platform for electronics design that provides version control, collaboration tools, component management, and more in one integrated solution. It is an alternative to using a generic version control system (VCS) like Git or Subversion to manage PCB projects.

While a vanilla VCS can work for electronics design, it lacks many of the specialized features and integrations that make Altium365 a more comprehensive solution. Let’s explore the key differences and advantages of using Altium365 compared to a standard VCS.

Key Features of Altium365

Altium365 provides several core features tailored for electronics design:

| Feature | Description |

|---|---|

| Version Control | Manages versions and revisions of schematics, PCBs, libraries, and projects |

| Component Management | Centralized component library with supply chain info, parametric search, and more |

| Collaboration Tools | Commenting, notifications, and project dashboards for team coordination |

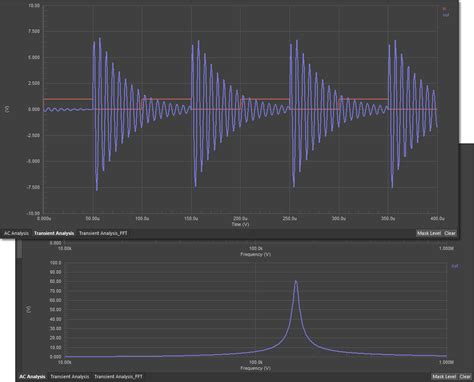

| Visualization | 3D rendering, MCAD integration, and manufacturing file outputs |

| Integrations | Connects with Altium Designer, Concord Pro, JIRA, and more |

These specialized capabilities go beyond what a generic VCS provides to better support the intricacies of the electronics development process from design to manufacture.

Unified Design Environment

One of the biggest advantages of Altium365 is how it unifies the entire electronics design workflow in one cloud platform. Designers can perform schematic capture, PCB layout, library management, and generate manufacturing outputs all through the Browser-Based Interface or the Altium Designer client.

This provides a single source of truth for the project and eliminates the need to manually sync data between multiple disparate tools. Everyone works off the same live data in real-time.

In contrast, using a separate VCS requires manually exporting design files, uploading them to the VCS, and downloading them again in the PCB design tool. This introduces extra steps where errors can occur.

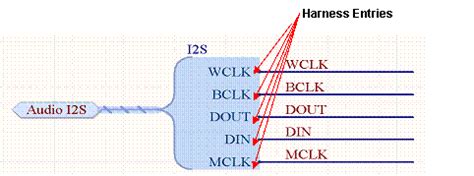

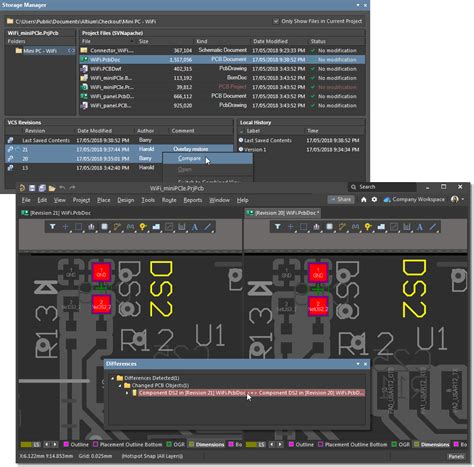

Visual Diff and History

Altium365 includes visual diff and history features tailored for electronics design. Designers can graphically see highlighted differences in schematics and PCBs between versions:

This allows quickly identifying changes without having to open each source file and compare them manually. The graphical representation is more intuitive than viewing a text-based diff.

The history view also shows a timeline of revisions for a design with thumbnails, which is more browsable compared to a generic VCS history that only shows file names and commit messages.

Component Management

Another key area where Altium365 excels is component management. It provides a centralized library where designers can store components with full supply chain information like manufacturer part numbers, sourcing options, pricing, and compliance info.

Features of the Altium365 component library include:

- Unified component database accessible by the whole team

- Managed lifecycles and revision tracking

- Parametric search and filtering

- Built-in supply chain data from partners

- Where-used information

- Datasheet and MCAD model attachments

- Alternate part linking

Managing components effectively is critical for electronics design, but a vanilla VCS lacks any built-in capabilities for it. Using Altium365, designers spend less time hunting down component data and can make informed part selections.

MCAD Collaboration

Mechanical CAD (MCAD) collaboration is another area where Altium365 provides an advantage. It has built-in features for working with mechanical engineers.

Altium365 provides:

- STEP model export/import

- MCAD view of the PCB in 3D

- Collision detection between PCB and enclosure

- Comment sharing between electrical and mechanical domains

These capabilities allow for a more streamlined ECAD/MCAD collaboration process compared to manually sharing design files with mechanical engineers and using a generic VCS as a go-between.

Other Considerations

Security

Altium365 incorporates strict security measures to protect sensitive design data. It uses encryption, access controls, and advanced threat detection.

Some teams may still prefer to keep all data in-house with a self-hosted VCS, but Altium365’s security practices meet or exceed industry standards to mitigate risks. Data is backed up across multiple geographic locations to ensure availability.

Cost

Altium365 is a paid platform, while open source VCS solutions are free. However, the productivity gains from using Altium365’s specialized feature set can outweigh the cost.

Electronics companies should evaluate the total cost of ownership. Using a less efficient tool can lead to delays or quality issues. The time savings enabled by Altium365 allow engineers to focus on design work that drives revenue rather than administrivia.

Integrations

Vanilla VCS tools tend to integrate with a wider variety of other software development tools compared to Altium365. However, Altium365 integrates with the most important tools for electronics design.

Altium365 connects with:

- Altium Designer

- Concord Pro

- JIRA issue tracking

- CMC (manufacturing partner)

- Arena PLM

For most electronics design use cases, these integrations cover the needed capabilities. But some teams may require other niche tool integrations that are only possible with a vanilla VCS.

Real-World Examples

Several electronics companies have adopted Altium365 and seen significant benefits compared to their previous generic VCS setups:

Radwave Technologies

Radwave Technologies is an aerospace electronics manufacturer. They migrated from using GitHub to manage PCB projects to Altium365.

“Altium365 transformed our whole development process. We can now go from concept to manufacturable designs 50% faster. The productivity gains have been immense.” – Jeff Lyons, VP of Engineering

| Metric | Before Altium365 | With Altium365 |

|---|---|---|

| Average project duration | 8 months | 4.5 months |

| PCB respins | 4 | 2 |

| Monthly output | 2 PCBs | 5 PCBs |

Adopting Altium365 allowed Radwave to streamline their workflow and collaborate more effectively, doubling their output.

GMH Industrial

GMH Industrial uses Altium365 to develop IoT sensor devices across several global design centers. They previously used Subversion.

“Managing component data was a huge problem with our old system. Altium365 component management has been a game-changer. We can now optimize our BOM in real-time.” – Lisa Petrov, Senior EE

| Metric | Before Altium365 | With Altium365 |

|---|---|---|

| BOM cost reduction | 5% | 28% |

| Unique parts per BOM | 210 | 105 |

| Annual cost savings | $250K | $1.2M |

GMH was able to drive cost savings and design more affordable products by taking advantage of Altium365’s supply chain aware component management.

FAQ

Can I use Altium365 with other PCB design tools besides Altium Designer?

No, Altium365 only integrates with Altium Designer currently. It is not intended to be a generic VCS that can be used with any tool.

Does Altium365 support branching and merging?

Yes, Altium365 supports branching design projects to work on separate features and merging branches back in, similar to other VCS solutions. However, the actual implementation through the Altium365 interface is optimized for electronics design workflows.

Is there a self-hosted version of Altium365 available?

No, Altium365 is only available as a cloud-hosted platform. For customers that require keeping all data on-premises, a generic self-hosted VCS may be the only option.

How does Altium365 handle conflicts when multiple people edit the same design?

Altium365 locks PCB files when someone has them checked out to avoid overwriting work. For schematics and other text-based files, it follows a “last commit wins” model. It does not have an automatic merge conflict resolution feature.

What happens to my data if I stop subscribing to Altium365?

Altium has a data export policy where they will provide an archive of a customer’s design files if they choose to stop using the platform. However, the data will no longer be accessible through the Altium365 interface and features after ending a subscription.

Conclusion

In summary, Altium365 provides significant advantages over a vanilla version control system for electronics design. Its tailored feature set, unified platform, component management capabilities, and MCAD integration allow for a more efficient and streamlined development process.

While a generic VCS can work for PCB projects, it requires more manual effort and lacks key electronics-specific capabilities. Adopting Altium365 enables companies to bring products to market faster while ensuring design data integrity.

If your team is currently using a vanilla VCS to manage PCB projects, consider evaluating Altium365 to see how it could improve your workflow. The potential time and cost savings are substantial for most professional electronics design organizations.

No responses yet