What is a PCB BOM Management Tool?

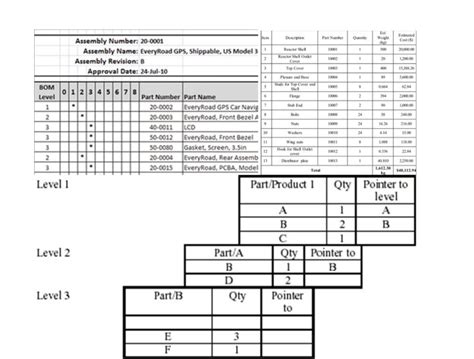

A PCB BOM management tool is a software application that helps electronics manufacturers create, manage, and maintain accurate BOMs for their PCB projects. It provides a centralized database for storing and organizing component information, including part numbers, descriptions, quantities, suppliers, and pricing.

Key Features of a PCB BOM Management Tool

| Feature | Description |

|---|---|

| Component Database | Centralized repository for storing and organizing component information |

| BOM Creation | Automated creation of BOMs based on PCB design files |

| BOM Validation | Checks for errors, inconsistencies, and obsolete components in the BOM |

| Supplier Management | Manages supplier information and pricing for components |

| Integration | Integrates with other tools in the PCB design and manufacturing workflow |

Benefits of Using a PCB BOM Management Tool

1. Improved Accuracy and Consistency

One of the primary benefits of using a PCB BOM management tool is improved accuracy and consistency in the BOM. By automating the BOM creation process and validating the BOM against the PCB design, the tool helps eliminate errors and inconsistencies that can arise from manual data entry and updates.

Common BOM Errors

- Missing or incorrect part numbers

- Inconsistent component descriptions

- Incorrect quantities

- Obsolete or discontinued components

A PCB BOM management tool can catch these errors early in the design process, reducing the risk of costly mistakes and delays in manufacturing.

2. Increased Efficiency and Productivity

Managing BOMs manually can be a time-consuming and tedious process, especially for complex PCB designs with hundreds or thousands of components. A PCB BOM management tool streamlines the BOM creation and management process, allowing engineers and procurement teams to work more efficiently and productively.

Streamlined BOM Creation

- Automated BOM generation from PCB design files

- Bulk editing and updating of component information

- Reuse of common components across multiple projects

By automating repetitive tasks and providing tools for bulk editing and updating, a PCB BOM management tool can significantly reduce the time and effort required to create and maintain accurate BOMs.

3. Better Collaboration and Communication

A PCB BOM management tool provides a centralized platform for collaboration and communication among the various stakeholders involved in the PCB design and manufacturing process, including engineers, procurement teams, suppliers, and contract manufacturers.

Collaborative Features

- Role-based access control

- Version control and change tracking

- Commenting and annotation

- Integration with other tools (e.g., PLM, ERP)

By providing a single source of truth for the BOM and enabling real-time collaboration and communication, a PCB BOM management tool helps ensure that everyone is working from the same up-to-date information and reduces the risk of miscommunication and delays.

4. Cost Savings and Risk Reduction

Using a PCB BOM management tool can help electronics manufacturers save costs and reduce risks in several ways:

Cost Savings

- Identifies obsolete or discontinued components early in the design process

- Enables volume pricing and supplier negotiations

- Reduces the risk of production delays and rework due to BOM errors

Risk Reduction

- Ensures compliance with regulatory requirements (e.g., RoHS, REACH)

- Tracks component lifecycle information and end-of-life (EOL) notifications

- Facilitates alternate component sourcing and supply chain resilience

By proactively managing component information and supplier relationships, a PCB BOM management tool helps manufacturers avoid costly mistakes, production delays, and supply chain disruptions.

Choosing the Right PCB BOM Management Tool

With many PCB BOM management tools available on the market, choosing the right one for your organization can be a challenge. Here are some key factors to consider:

Key Selection Criteria

| Criteria | Description |

|---|---|

| Ease of Use | The tool should be intuitive and easy to learn and use for all stakeholders |

| Scalability | The tool should be able to handle the complexity and volume of your PCB projects |

| Integration | The tool should integrate seamlessly with your existing PCB design and manufacturing tools |

| Customization | The tool should be customizable to meet your organization’s specific needs and workflows |

| Support | The vendor should provide reliable technical support and training resources |

Implementing a PCB BOM Management Tool

Once you have selected a PCB BOM management tool, the next step is to implement it effectively within your organization. Here are some best practices to follow:

Implementation Best Practices

- Define clear goals and objectives for the implementation

- Involve all relevant stakeholders in the planning and execution

- Establish standardized processes and workflows for BOM management

- Provide training and support for users

- Monitor and measure the effectiveness of the tool and make continuous improvements

By following these best practices, you can ensure a smooth and successful implementation of your PCB BOM management tool and start realizing the benefits of improved accuracy, efficiency, and collaboration in your PCB design and manufacturing process.

Frequently Asked Questions (FAQ)

1. What is the difference between a PCB BOM and a regular BOM?

A PCB BOM is specific to the components and materials required to manufacture a printed circuit board, while a regular BOM can refer to any bill of materials used in manufacturing or construction.

2. Can a PCB BOM management tool integrate with my existing CAD tools?

Yes, most PCB BOM management tools offer integration with popular CAD tools such as Altium Designer, Cadence Allegro, and Mentor Graphics PADS, enabling automated BOM generation from PCB design files.

3. How does a PCB BOM management tool handle Component Obsolescence?

A PCB BOM management tool can track component lifecycle information and provide alerts for obsolete or discontinued components, allowing engineers to proactively find suitable replacements and avoid production delays.

4. Can multiple users access and edit the BOM simultaneously in a PCB BOM management tool?

Yes, most PCB BOM management tools offer collaborative features such as role-based access control, version control, and real-time updates, enabling multiple users to access and edit the BOM simultaneously while maintaining data integrity.

5. How much does a PCB BOM management tool cost?

The cost of a PCB BOM management tool varies depending on the vendor, features, and scale of deployment. Some tools offer subscription-based pricing, while others require a one-time license fee. It’s best to request a quote from the vendor based on your specific needs and requirements.

Conclusion

In today’s fast-paced and competitive electronics industry, effective PCB BOM management is critical for success. A PCB BOM management tool offers numerous benefits, including improved accuracy and consistency, increased efficiency and productivity, better collaboration and communication, and cost savings and risk reduction.

By choosing the right tool and implementing it effectively within your organization, you can streamline your PCB design and manufacturing process, reduce errors and delays, and ultimately deliver high-quality products to your customers faster and more cost-effectively.

No responses yet