What is a Semiconductor PCB?

A semiconductor PCB is a specialized type of printed circuit board that utilizes semiconductor materials, such as silicon, germanium, or gallium arsenide, as the base substrate. Unlike traditional PCBs that use insulating materials like FR-4, semiconductor PCBs leverage the unique electrical properties of semiconductors to enable advanced functionalities and performance.

Key Characteristics of Semiconductor PCBs

Semiconductor PCBs exhibit several distinct characteristics that set them apart from conventional PCBs:

- High thermal conductivity: Semiconductor materials have excellent thermal conductivity, allowing for efficient heat dissipation and temperature management.

- Enhanced electrical properties: Semiconductors offer precise control over electrical conductivity, enabling the creation of integrated circuits and active components directly on the PCB.

- Miniaturization: Semiconductor PCBs enable the fabrication of highly miniaturized circuits, making them ideal for compact and portable devices.

- High-frequency operation: The inherent properties of semiconductors allow semiconductor PCBs to handle high-frequency signals and support high-speed data transmission.

| Property | Semiconductor PCB | Traditional PCB |

|---|---|---|

| Base Material | Semiconductor | Insulating |

| Thermal Conductivity | High | Low |

| Electrical Conductivity | Controllable | Fixed |

| Miniaturization | Excellent | Limited |

| High-Frequency Support | Superior | Limited |

Construction of Semiconductor PCBs

The manufacturing process of semiconductor PCBs involves several intricate steps to achieve the desired electrical and mechanical properties. Let’s take a closer look at the key stages in the construction of semiconductor PCBs.

Substrate Preparation

The first step in creating a semiconductor PCB is the preparation of the semiconductor substrate. This involves growing a single crystal of the chosen semiconductor material, such as silicon, using techniques like the Czochralski method or float-zone crystal growth. The resulting wafer is then sliced into thin discs that serve as the base for the PCB.

Doping and Patterning

To create the desired electrical properties, the semiconductor substrate undergoes a process called doping. Doping involves introducing impurities into the semiconductor material to control its conductivity. This is typically achieved through ion implantation or diffusion techniques.

After doping, the semiconductor substrate is patterned using photolithography. This process involves applying a light-sensitive photoresist layer, exposing it to a pattern of light, and developing it to create a mask. The mask is then used to selectively etch or deposit materials on the substrate, forming the desired circuit patterns.

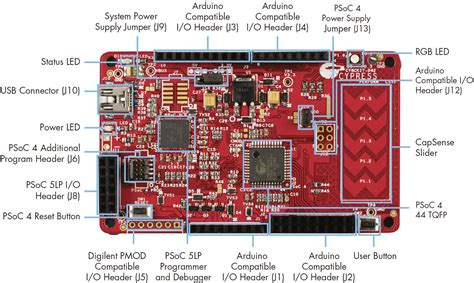

Metallization and Interconnections

Once the circuit patterns are formed, a metallization process is carried out to create conductive paths and interconnections. This usually involves depositing a thin layer of metal, such as copper or aluminum, onto the semiconductor substrate using techniques like sputtering or electroplating.

The metallized substrate is then patterned again using photolithography to define the desired interconnections and contact pads. Additional layers of dielectric materials, such as silicon dioxide or silicon nitride, may be deposited to provide insulation between the metal layers.

Packaging and Assembly

After the semiconductor PCB is fabricated, it undergoes a packaging process to protect the delicate circuits and provide electrical connections to the outside world. This can involve various packaging techniques, such as wire bonding, flip-chip bonding, or ball grid array (BGA) packaging.

Finally, the packaged semiconductor PCB is assembled onto a larger PCB or integrated into a complete device, depending on the specific application requirements.

Advantages of Semiconductor PCBs

Semiconductor PCBs offer several advantages over traditional PCBs, making them highly desirable for certain applications:

- Integration of active components: Semiconductor PCBs allow for the integration of active components, such as transistors and diodes, directly onto the PCB substrate. This eliminates the need for separate discrete components and enables higher levels of integration and functionality.

- Improved signal integrity: The inherent properties of semiconductors, such as low resistivity and high carrier mobility, contribute to improved signal integrity and reduced signal losses. This is particularly beneficial for high-frequency and high-speed applications.

- Enhanced thermal management: Semiconductor materials have excellent thermal conductivity, enabling efficient heat dissipation from the PCB. This is crucial for devices that generate significant amounts of heat, such as power electronics or high-performance computing systems.

- Miniaturization and space savings: Semiconductor PCBs enable the fabrication of highly miniaturized circuits, allowing for compact and lightweight devices. This is particularly advantageous for portable electronics, wearables, and IoT devices where space is at a premium.

- Customization and flexibility: Semiconductor PCBs offer a high degree of customization and flexibility in terms of circuit design and functionality. The ability to control the electrical properties of the substrate and integrate active components allows for tailored solutions to meet specific application requirements.

Applications of Semiconductor PCBs

Semiconductor PCBs find applications in a wide range of modern-day devices, spanning various industries and sectors. Some notable applications include:

Consumer Electronics

Semiconductor PCBs are extensively used in consumer electronics, such as smartphones, tablets, laptops, and wearable devices. They enable the integration of advanced features, such as high-resolution displays, camera modules, and wireless connectivity, while maintaining a compact form factor.

Automotive Electronics

In the automotive industry, semiconductor PCBs play a vital role in powering various electronic systems, including engine control units (ECUs), infotainment systems, advanced driver assistance systems (ADAS), and electric vehicle power electronics. The high thermal conductivity and reliability of semiconductor PCBs make them well-suited for the harsh automotive environment.

Medical Devices

Semiconductor PCBs are employed in a range of medical devices, from diagnostic equipment and imaging systems to implantable devices and wearable health monitors. The miniaturization capabilities and high-frequency operation of semiconductor PCBs enable the development of compact and high-performance medical devices.

Telecommunications and Networking

In the telecommunications and networking sector, semiconductor PCBs are used in routers, switches, base stations, and other network infrastructure equipment. The high-speed data transmission and signal integrity provided by semiconductor PCBs are essential for supporting the ever-increasing bandwidth demands of modern communication networks.

Aerospace and Defense

Semiconductor PCBs find applications in aerospace and defense systems, such as avionics, radar systems, and satellites. The ability to withstand extreme environmental conditions and provide reliable performance makes semiconductor PCBs a preferred choice for mission-critical applications.

Challenges and Future Developments

While semiconductor PCBs offer numerous advantages, they also present certain challenges and opportunities for future developments:

Manufacturing Complexity

The fabrication of semiconductor PCBs involves complex processes and requires specialized equipment and expertise. The need for precise control over doping, patterning, and metallization adds to the manufacturing complexity compared to traditional PCBs. Ongoing research focuses on simplifying and optimizing the manufacturing processes to reduce costs and improve yields.

Thermal Management

Although semiconductor PCBs have inherent thermal management advantages, the increasing power densities and miniaturization of electronic devices pose challenges in terms of heat dissipation. Advanced thermal management solutions, such as heat spreaders, Thermal Interface materials, and liquid cooling, are being explored to address these challenges.

Integration with Emerging Technologies

Semiconductor PCBs are poised to play a crucial role in the integration of emerging technologies, such as 5G networks, artificial intelligence (AI), and the Internet of Things (IoT). The high-frequency capabilities and miniaturization potential of semiconductor PCBs make them well-suited for supporting these technologies. Continued research and development efforts aim to enhance the performance and functionality of semiconductor PCBs to meet the demands of these evolving technologies.

Environmental Considerations

As with any electronic technology, the environmental impact of semiconductor PCBs is an important consideration. Efforts are being made to develop eco-friendly and sustainable manufacturing processes, as well as to improve the recycling and disposal of semiconductor PCBs at the end of their lifecycle. Regulations and industry initiatives are driving the adoption of greener practices in the semiconductor PCB industry.

Frequently Asked Questions (FAQ)

-

What is the main difference between a semiconductor PCB and a traditional PCB?

The main difference lies in the base material used. Semiconductor PCBs utilize semiconductor materials like silicon as the substrate, while traditional PCBs use insulating materials like FR-4. This difference gives semiconductor PCBs unique electrical and thermal properties. -

What are the advantages of using semiconductor PCBs?

Semiconductor PCBs offer several advantages, including the integration of active components, improved signal integrity, enhanced thermal management, miniaturization and space savings, and customization flexibility. -

In which industries are semiconductor PCBs commonly used?

Semiconductor PCBs find applications in various industries, including consumer electronics, automotive electronics, medical devices, telecommunications and networking, aerospace and defense, among others. -

What challenges are associated with the manufacturing of semiconductor PCBs?

The manufacturing of semiconductor PCBs involves complex processes, such as doping, patterning, and metallization, which require specialized equipment and expertise. This complexity adds to the manufacturing challenges compared to traditional PCBs. -

How are semiconductor PCBs contributing to emerging technologies?

Semiconductor PCBs play a crucial role in supporting emerging technologies like 5G networks, artificial intelligence (AI), and the Internet of Things (IoT). Their high-frequency capabilities and miniaturization potential make them well-suited for these applications, driving continued research and development efforts.

Conclusion

Semiconductor PCBs have revolutionized the electronics industry by offering unique properties and capabilities that traditional PCBs cannot match. With their ability to integrate active components, improve signal integrity, enhance thermal management, and enable miniaturization, semiconductor PCBs have become the backbone of modern-day devices across various sectors.

As technology continues to advance, semiconductor PCBs are poised to play an even greater role in shaping the future of electronics. From consumer gadgets to medical devices, automotive systems to aerospace applications, semiconductor PCBs will continue to drive innovation and push the boundaries of what is possible.

However, the semiconductor PCB industry also faces challenges in terms of manufacturing complexity, thermal management, and environmental considerations. Ongoing research and development efforts aim to address these challenges and unlock the full potential of semiconductor PCBs.

As we move forward, the versatility and capabilities of semiconductor PCBs will undoubtedly shape the landscape of electronic devices, enabling the development of more advanced, efficient, and compact solutions. With their ability to adapt and evolve, semiconductor PCBs will remain a critical component in the ever-changing world of electronics.

No responses yet