Introduction to PCB and its Importance

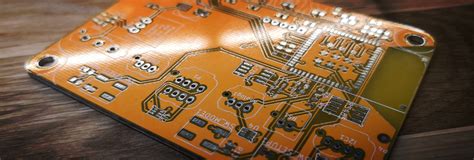

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are used in almost every electronic device, from smartphones and computers to medical equipment and aerospace systems. PCBs are essential because they provide a reliable and efficient way to connect electronic components and allow for the creation of complex circuits in a compact space.

In this comprehensive guide, we will explore various aspects of PCB design, manufacturing, and troubleshooting. By the end of this article, you will have a better understanding of how to create high-quality PCBs and overcome common challenges.

What is a PCB?

A PCB is a flat board made of insulating materials, such as fiberglass or plastic, with conductive copper tracks printed on its surface. These tracks connect various electronic components, such as resistors, capacitors, and integrated circuits (ICs), to form a complete circuit.

PCBs come in different types, depending on the number of layers and the density of the components:

| PCB Type | Description |

|---|---|

| Single-layer | Has conductive tracks on one side only |

| Double-layer | Has conductive tracks on both sides |

| Multi-layer | Has multiple layers of conductive tracks separated by insulating layers |

Why are PCBs important?

PCBs offer several advantages over traditional point-to-point wiring:

- Compact size: PCBs allow for the creation of complex circuits in a small space, making electronic devices more portable and efficient.

- Reliability: The sturdy construction of PCBs ensures that connections remain secure and stable, even under harsh conditions.

- Cost-effective: Mass production of PCBs is relatively inexpensive, making them an economical choice for large-scale manufacturing.

- Ease of maintenance: PCBs make it easier to identify and replace faulty components, reducing downtime and repair costs.

PCB Design Tips

Designing a PCB requires careful planning and attention to detail. Here are some essential tips to keep in mind when designing your PCB:

Choose the right software

There are many PCB design software options available, ranging from free open-source tools to expensive commercial packages. Some popular choices include:

- KiCad

- Eagle

- Altium Designer

- OrCAD

When selecting a software, consider factors such as ease of use, feature set, and compatibility with your manufacturing process.

Keep track of component footprints

Ensure that you have accurate footprints for all the components you plan to use in your design. Footprints define the physical dimensions and pin layout of a component, and using the wrong footprint can lead to manufacturing issues.

Follow design rules

Adhere to the design rules specified by your PCB manufacturer, such as minimum track width, clearance between tracks, and hole sizes. Violating these rules can result in production delays or even board failures.

Use a grid system

Working with a grid system helps maintain consistency and makes it easier to align components and tracks. Most PCB design software allows you to set up a custom grid to suit your needs.

Consider signal integrity

High-speed digital circuits are susceptible to signal integrity issues, such as crosstalk and reflections. To minimize these problems:

- Keep track lengths as short as possible

- Use proper termination techniques

- Avoid sharp bends in tracks

- Maintain adequate spacing between sensitive signals

Plan for manufacturing

Design your PCB with manufacturing in mind. For example, provide sufficient space for tooling holes, keep components away from board edges, and use standard sizes when possible to reduce costs.

PCB Manufacturing Process

Once your PCB design is complete, it’s time to send it for manufacturing. Here’s a brief overview of the PCB manufacturing process:

- Solder mask application: A layer of polymer is applied to the PCB to protect the copper tracks from oxidation and prevent solder bridges.

- Silkscreen printing: Component labels, logos, and other markings are printed on the PCB using a silkscreen process.

- Drilling: Holes are drilled in the PCB to accommodate through-hole components and vias.

- Plating: The drilled holes are plated with copper to establish electrical connections between layers.

- Etching: Unwanted copper is removed from the PCB using a chemical etching process, leaving only the desired tracks.

- Surface finish: A protective coating, such as HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold), is applied to the exposed copper to prevent oxidation and improve solderability.

- Electrical testing: The manufactured PCBs undergo electrical testing to ensure they meet the specified requirements and are free from defects.

Choosing a PCB manufacturer

When selecting a PCB manufacturer, consider the following factors:

- Experience: Look for a manufacturer with a proven track record of producing high-quality PCBs.

- Capabilities: Ensure that the manufacturer can handle your specific requirements, such as board size, layer count, and surface finish.

- Lead time: Check the manufacturer’s lead time to ensure it aligns with your project timeline.

- Cost: Compare prices from multiple manufacturers to find the best value for your budget.

- Communication: Choose a manufacturer that is responsive and easy to communicate with, as this can help prevent misunderstandings and delays.

PCB Assembly Tips

After receiving your manufactured PCBs, the next step is to assemble the components onto the board. Here are some tips to ensure a successful PCB assembly:

Use the right tools

Invest in quality soldering tools, such as a temperature-controlled soldering iron, tweezers, and a magnifying lamp. These tools will help you work more efficiently and accurately.

Follow ESD precautions

Electrostatic discharge (ESD) can damage sensitive electronic components. To prevent ESD damage:

- Wear an antistatic wrist strap

- Use an ESD-safe work surface

- Handle components by their edges

Apply solder paste correctly

If you’re using surface mount components, apply solder paste evenly and accurately using a stencil or syringe. Too much or too little solder paste can lead to poor connections or short circuits.

Inspect your work

After soldering, inspect your work using a magnifying glass or microscope to ensure that all connections are properly made and there are no solder bridges or cold joints.

Use a reflow oven for SMD components

For surface mount devices (SMDs), using a reflow oven can help ensure consistent and reliable solder joints. Follow the manufacturer’s recommended temperature profile for the best results.

PCB Troubleshooting Techniques

Even with careful design and assembly, PCBs can sometimes develop faults. Here are some troubleshooting techniques to help you identify and resolve issues:

Visual inspection

Carefully examine the PCB for any visible defects, such as damaged components, solder bridges, or broken tracks. Use a magnifying glass or microscope to inspect small details.

Continuity testing

Use a multimeter to test for continuity between points on the PCB. This can help identify open circuits or short circuits.

Power supply checks

Ensure that the PCB is receiving the correct voltage and current from the power supply. Use a multimeter to measure the voltage at various points on the board.

Signal tracing

Use an oscilloscope to trace signals through the PCB and identify any abnormalities, such as distortion or attenuation.

Thermal imaging

A thermal imaging camera can help identify components that are overheating, which may indicate a fault or design issue.

Component substitution

If you suspect a particular component is faulty, try replacing it with a known good one to see if the issue is resolved.

Frequently Asked Questions (FAQ)

1. What is the difference between a single-layer and a multi-layer PCB?

A Single-Layer PCB has conductive tracks on one side only, while a multi-layer PCB has multiple layers of conductive tracks separated by insulating layers. Multi-layer PCBs offer higher component density and better signal integrity but are more expensive to manufacture.

2. How do I choose the right PCB manufacturer for my project?

When choosing a PCB manufacturer, consider factors such as experience, capabilities, lead time, cost, and communication. Look for a manufacturer with a proven track record of producing high-quality PCBs that can handle your specific requirements and provide good value for your budget.

3. What are some common PCB design mistakes to avoid?

Some common PCB design mistakes include using the wrong component footprints, violating design rules, neglecting signal integrity, and failing to plan for manufacturing. To avoid these mistakes, choose the right software, keep track of component footprints, follow design rules, consider signal integrity, and design with manufacturing in mind.

4. How can I prevent ESD damage when assembling PCBs?

To prevent ESD damage, wear an antistatic wrist strap, use an ESD-safe work surface, and handle components by their edges. These precautions help dissipate static charges and protect sensitive electronic components from damage.

5. What should I do if my PCB is not working properly?

If your PCB is not working properly, start by performing a visual inspection to identify any visible defects. Then, use techniques such as continuity testing, power supply checks, signal tracing, thermal imaging, and component substitution to diagnose and resolve the issue. If the problem persists, consult with an experienced technician or engineer for further assistance.

Conclusion

PCBs are essential components in modern electronics, and understanding how to design, manufacture, and troubleshoot them is crucial for anyone working in the field. By following the tips and techniques outlined in this guide, you can create high-quality PCBs that meet your specific requirements and overcome common challenges.

Remember to choose the right software, keep track of component footprints, follow design rules, consider signal integrity, and plan for manufacturing when designing your PCB. When selecting a manufacturer, look for experience, capabilities, lead time, cost, and good communication.

During assembly, use the right tools, follow ESD precautions, apply solder paste correctly, inspect your work, and use a reflow oven for SMD components. If you encounter issues, employ troubleshooting techniques such as visual inspection, continuity testing, power supply checks, signal tracing, thermal imaging, and component substitution.

By mastering these skills and staying up-to-date with the latest trends and technologies, you can become proficient in PCB design and manufacturing, and contribute to the ever-evolving world of electronics.

No responses yet