Introduction to PCB Materials

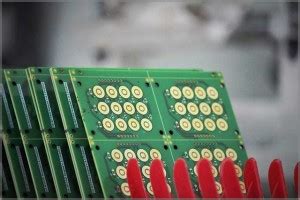

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They provide a platform for electronic components to be mounted and connected, enabling the creation of complex circuits that power everything from smartphones to spacecraft. The choice of materials used in PCB manufacturing is critical to the performance, reliability, and cost of the final product. In this ultimate guide, we will explore the various types of PCB materials, their properties, and their applications.

Types of PCB Materials

FR-4

FR-4 is the most commonly used PCB material. It is a composite material made of woven fiberglass cloth with an epoxy resin binder. FR-4 has good mechanical strength, electrical insulation, and thermal stability, making it suitable for a wide range of applications. It is also relatively inexpensive compared to other PCB materials.

| Property | Value |

|---|---|

| Dielectric Constant | 4.5 @ 1 MHz |

| Dissipation Factor | 0.02 @ 1 MHz |

| Thermal Conductivity | 0.3 W/m·K |

| Tg (Glass Transition Temperature) | 130-140°C |

| CTE (Coefficient of Thermal Expansion) | 14-16 ppm/°C |

High Tg FR-4

High Tg FR-4 is a variant of standard FR-4 with improved thermal stability. It has a higher glass transition temperature (Tg), typically around 170-180°C, which allows it to withstand higher processing temperatures during assembly and operation. High Tg FR-4 is often used in automotive, aerospace, and military applications where reliability under extreme conditions is critical.

Polyimide

Polyimide is a high-performance polymer that offers excellent thermal stability, chemical resistance, and mechanical strength. It has a low dielectric constant and low dissipation factor, making it suitable for high-frequency applications. Polyimide PCBs can operate at temperatures up to 260°C and are often used in aerospace, military, and medical devices.

| Property | Value |

|---|---|

| Dielectric Constant | 3.5 @ 1 MHz |

| Dissipation Factor | 0.002 @ 1 MHz |

| Thermal Conductivity | 0.2 W/m·K |

| Tg (Glass Transition Temperature) | 260°C |

| CTE (Coefficient of Thermal Expansion) | 12-16 ppm/°C |

Rogers Materials

Rogers Corporation produces a range of high-frequency PCB materials designed for RF and microwave applications. These materials have low dielectric constants, low dissipation factors, and excellent thermal stability, enabling the fabrication of high-performance circuits for telecommunications, radar, and satellite systems.

Some popular Rogers materials include:

- RO4000 Series: A hydrocarbon ceramic laminate with low dielectric constant and low loss.

- RT/duroid® 5000 Series: A PTFE composite with low dielectric constant and low loss.

- RO3000® Series: A ceramic-filled PTFE composite with low dielectric constant and low loss.

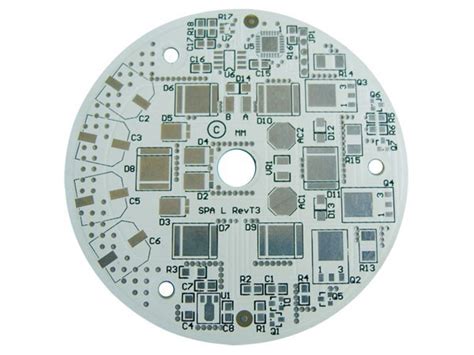

Aluminum PCBs

Aluminum PCBs use an aluminum substrate instead of the traditional FR-4 or other dielectric materials. The aluminum substrate provides excellent thermal conductivity, allowing heat to be dissipated efficiently from power-hungry components. Aluminum PCBs are often used in LED lighting, automotive electronics, and power electronics applications.

PCB Material Properties

When selecting a PCB material, several key properties must be considered to ensure the material is suitable for the intended application. These properties include:

Dielectric Constant (Dk)

The dielectric constant, also known as relative permittivity, is a measure of a material’s ability to store electrical energy in an electric field. A lower dielectric constant is desirable for high-frequency applications, as it reduces signal Propagation Delay and minimizes signal loss.

Dissipation Factor (Df)

The dissipation factor, also known as loss tangent, is a measure of a material’s energy loss in an alternating electric field. A lower dissipation factor is desirable for high-frequency applications, as it minimizes signal attenuation and improves signal integrity.

Thermal Conductivity

Thermal conductivity is a measure of a material’s ability to conduct heat. A higher thermal conductivity is desirable for applications that generate significant amounts of heat, as it helps to dissipate heat more efficiently and prevents components from overheating.

Glass Transition Temperature (Tg)

The glass transition temperature is the temperature at which a material transitions from a rigid, glassy state to a softer, rubbery state. A higher Tg is desirable for applications that require high-temperature operation or processing, as it ensures the material maintains its mechanical and electrical properties at elevated temperatures.

Coefficient of Thermal Expansion (CTE)

The coefficient of thermal expansion is a measure of a material’s dimensional change in response to a change in temperature. A lower CTE is desirable for applications that require dimensional stability, as it minimizes stress and strain on components and solder joints during thermal cycling.

PCB material selection Considerations

When selecting a PCB material, several factors must be considered to ensure the material is suitable for the intended application. These factors include:

Frequency of Operation

The frequency of operation is a critical factor in selecting a PCB material. For high-frequency applications, materials with low dielectric constants and low dissipation factors are essential to minimize signal loss and maintain signal integrity.

Operating Temperature Range

The operating temperature range of the application must be considered when selecting a PCB material. Materials with high Tg and low CTE are necessary for applications that operate at high temperatures or undergo significant thermal cycling.

Mechanical Requirements

The mechanical requirements of the application, such as flexibility, strength, and durability, must be considered when selecting a PCB material. Some materials, such as polyimide, offer excellent mechanical properties, while others, such as FR-4, may be more suitable for rigid, cost-sensitive applications.

Cost Considerations

The cost of the PCB material is an important consideration, especially for high-volume production. FR-4 is the most cost-effective option for many applications, while high-performance materials like polyimide and Rogers materials may be necessary for demanding applications despite their higher cost.

FAQ

Q1: What is the most common PCB material?

A1: FR-4 is the most widely used PCB material due to its good balance of properties and relatively low cost.

Q2: What PCB materials are best for high-frequency applications?

A2: Materials with low dielectric constants and low dissipation factors, such as Rogers materials and polyimide, are best suited for high-frequency applications.

Q3: What are the advantages of aluminum PCBs?

A3: Aluminum PCBs offer excellent thermal conductivity, which allows for efficient heat dissipation from power-hungry components. This makes them well-suited for applications like LED lighting, automotive electronics, and power electronics.

Q4: What is the glass transition temperature (Tg) and why is it important?

A4: The glass transition temperature is the temperature at which a material transitions from a rigid, glassy state to a softer, rubbery state. A higher Tg is desirable for applications that require high-temperature operation or processing, as it ensures the material maintains its mechanical and electrical properties at elevated temperatures.

Q5: How does the coefficient of thermal expansion (CTE) affect PCB performance?

A5: A lower CTE is desirable for applications that require dimensional stability, as it minimizes stress and strain on components and solder joints during thermal cycling. Materials with high CTEs can lead to reliability issues and reduced product lifetimes.

Conclusion

The selection of PCB materials is a critical aspect of PCB manufacturing that directly impacts the performance, reliability, and cost of the final product. By understanding the various types of PCB materials, their properties, and the key considerations for material selection, designers and manufacturers can make informed decisions that optimize their products for their intended applications. From the versatile FR-4 to high-performance materials like polyimide and Rogers materials, the right choice of PCB material can make all the difference in the success of an electronic device.

No responses yet