The Growth of PCB Manufacturing in India

The Indian electronics industry has witnessed remarkable growth in recent years, driven by increasing domestic consumption, government initiatives, and the global shift towards electronics manufacturing in the country. The PCB manufacturing sector, being a critical component of the electronics industry, has played a significant role in this growth story.

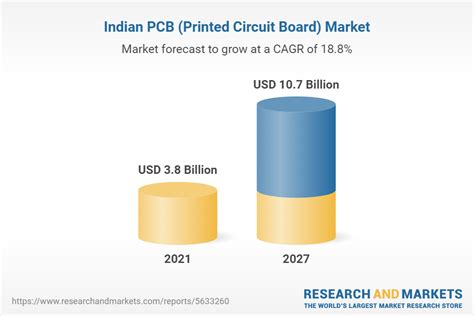

Market Size and Growth

According to a report by the India Electronics and Semiconductor Association (IESA), the Indian PCB market was valued at $4.2 billion in 2020 and is expected to reach $8.4 billion by 2025, growing at a CAGR of 14.7% during the forecast period. This growth can be attributed to several factors, including:

- Rising demand for consumer electronics

- Increasing adoption of automation in various industries

- Government initiatives to promote electronics manufacturing

- Growing focus on indigenous manufacturing

Government Initiatives

The Indian government has introduced several initiatives to boost electronics manufacturing in the country, including PCB production. Some of these initiatives include:

-

Make in India: Launched in 2014, this initiative aims to transform India into a global manufacturing hub by encouraging both domestic and foreign companies to manufacture their products in India.

-

Production Linked Incentive (PLI) Scheme: Introduced in 2020, the PLI scheme offers incentives to companies that manufacture electronics components, including PCBs, in India.

-

Electronics Manufacturing Clusters (EMC) Scheme: This scheme provides financial assistance for the development of electronics manufacturing clusters, which include PCB manufacturing units.

-

Scheme for Promotion of Manufacturing of Electronic Components and Semiconductors (SPECS): Launched in 2020, SPECS offers financial incentives to companies engaged in the manufacturing of electronic components, including PCBs.

Advantages of PCB Manufacturing in India

India offers several advantages that make it an attractive destination for PCB manufacturing:

Cost Competitiveness

One of the primary advantages of PCB manufacturing in India is the lower production costs compared to other countries. This can be attributed to factors such as:

- Availability of skilled labor at competitive wages

- Lower overhead costs

- Competitive pricing of raw materials

| Country | Average Hourly Wage (USD) |

|---|---|

| India | 1.50 – 3.00 |

| China | 3.50 – 6.00 |

| Vietnam | 2.50 – 4.50 |

| Thailand | 2.00 – 4.00 |

Source: Various industry reports

Skilled Workforce

India has a large pool of skilled engineers and technicians, thanks to its robust education system and emphasis on technical education. This skilled workforce is well-equipped to handle the complex processes involved in PCB manufacturing.

Growing Domestic Market

With a population of over 1.3 billion and a rapidly growing middle class, India presents a vast domestic market for electronic products. This growing demand for electronics translates into increased opportunities for PCB manufacturers in the country.

Strategic Location

India’s strategic location in South Asia makes it an ideal hub for exports to neighboring countries and other regions. Additionally, India has a well-developed port infrastructure, which facilitates the efficient movement of goods.

Challenges Faced by PCB Manufacturers in India

Despite the numerous advantages, PCB manufacturers in India face several challenges that need to be addressed:

Infrastructure Constraints

While India has made significant progress in developing its infrastructure, there are still some constraints that affect PCB manufacturing. These include:

- Inadequate power supply in certain regions

- Underdeveloped supply chain networks

- Insufficient availability of raw materials

Technological Gaps

Although India has made strides in PCB manufacturing technology, there is still a gap compared to countries like China and Taiwan. This is particularly evident in advanced PCB Technologies such as High-Density Interconnect (HDI) and Flexible PCBs.

Competition from Other Countries

India faces stiff competition from other countries in the region, such as China and Vietnam, which have established themselves as major players in the PCB manufacturing industry. These countries offer similar advantages in terms of cost competitiveness and skilled labor.

Future Prospects for PCB Manufacturing in India

Despite the challenges, the future of PCB manufacturing in India looks promising. The Indian government’s continued support through various initiatives, coupled with the growing domestic demand and the global shift towards electronics manufacturing in the country, is expected to drive the growth of the PCB manufacturing sector.

Increased Investments

As the Indian PCB market continues to grow, it is expected to attract more investments from both domestic and foreign companies. This influx of investments will help in the development of advanced PCB manufacturing facilities and the adoption of latest technologies.

Focus on Research and Development

To bridge the technological gap and stay competitive in the global market, Indian PCB manufacturers are expected to increase their focus on research and development (R&D). Collaborations between industry and academia can play a crucial role in driving innovation and developing indigenous technologies.

Shift towards High-Value Products

As the Indian PCB manufacturing sector matures, there is likely to be a shift towards the production of high-value products such as HDI and Flexible PCBs. This shift will be driven by the increasing demand for advanced electronic devices and the need to stay competitive in the global market.

Frequently Asked Questions (FAQ)

-

Q: What is the current market size of the Indian PCB industry?

A: As of 2020, the Indian PCB market was valued at $4.2 billion. -

Q: What are the key factors driving the growth of PCB manufacturing in India?

A: The growth of PCB manufacturing in India is driven by factors such as rising domestic demand for electronics, government initiatives to promote electronics manufacturing, and the global shift towards manufacturing in India. -

Q: What are some of the challenges faced by PCB manufacturers in India?

A: PCB manufacturers in India face challenges such as infrastructure constraints, technological gaps, and competition from other countries in the region. -

Q: What is the future outlook for PCB manufacturing in India?

A: The future of PCB manufacturing in India looks promising, with increased investments, a focus on research and development, and a shift towards the production of high-value products. -

Q: How does India compare to other countries in terms of PCB Manufacturing Costs?

A: India offers lower production costs compared to other countries, thanks to the availability of skilled labor at competitive wages, lower overhead costs, and competitive pricing of raw materials.

In conclusion, the PCB manufacturing industry in India is poised for significant growth in the coming years, driven by increasing domestic demand, government support, and the global shift towards electronics manufacturing in the country. While there are challenges to be addressed, the future prospects for PCB manufacturing in India remain promising, with opportunities for increased investments, innovation, and the production of high-value products.

No responses yet