Understanding PCB Impedance

PCB (Printed Circuit Board) impedance is a critical factor in the design and manufacturing of high-speed electronic circuits. It refers to the opposition to the flow of electrical current in a PCB trace, which can significantly impact signal integrity, power efficiency, and overall system performance. Accurately calculating and controlling PCB impedance is essential for ensuring reliable and efficient operation of electronic devices.

What is PCB Impedance?

PCB impedance is the combined effect of resistance, capacitance, and inductance in a PCB trace. It is measured in ohms (Ω) and represents the total opposition to the flow of alternating current (AC) in a circuit. The impedance of a PCB trace depends on various factors, including:

- Trace width and thickness

- Dielectric constant of the PCB material

- Spacing between traces

- Frequency of the signal

Controlling PCB impedance is crucial in high-speed digital circuits, where signal integrity and timing are critical. Mismatched impedances can lead to signal reflections, crosstalk, and other issues that can degrade system performance and reliability.

Types of PCB Impedance

There are two main types of PCB impedance:

-

Characteristic Impedance (Z0): This is the impedance of a transmission line in a PCB, which is determined by the geometry and materials of the trace and the surrounding dielectric. Characteristic impedance is important for maintaining signal integrity in high-speed digital circuits.

-

Differential Impedance (Zdiff): This is the impedance between two paired traces in a PCB, which is used for differential signaling. Differential impedance is essential for maintaining signal balance and reducing electromagnetic interference (EMI) in high-speed differential circuits.

Calculating PCB Impedance

Calculating PCB impedance involves using mathematical formulas that take into account the physical properties of the PCB traces and the surrounding dielectric material. The most commonly used formulas for calculating PCB impedance are:

Characteristic Impedance Formula

The characteristic impedance (Z0) of a PCB trace can be calculated using the following formula:

Z0 = 87 / √(εr + 1.41) * ln(5.98 * h / (0.8 * w + t))

Where:

– εr = Dielectric constant of the PCB material

– h = Height of the dielectric (distance between the trace and the reference plane)

– w = Width of the trace

– t = Thickness of the trace

Differential Impedance Formula

The differential impedance (Zdiff) of a pair of PCB traces can be calculated using the following formula:

Zdiff = 2 * Z0 * (1 – 0.48 * e^(-0.96 * s / h))

Where:

– Z0 = Characteristic impedance of a single trace

– s = Spacing between the traces

– h = Height of the dielectric (distance between the traces and the reference plane)

Factors Affecting PCB Impedance

Several factors can affect the impedance of a PCB trace, and it is important to consider these factors when designing and manufacturing PCBs for high-speed applications.

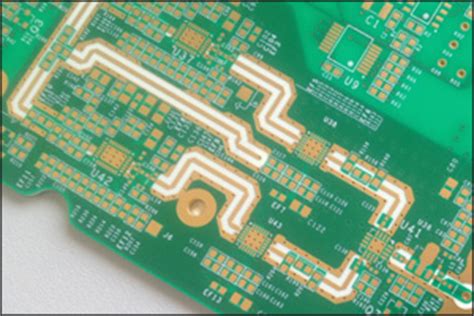

Trace Geometry

The width, thickness, and spacing of PCB traces have a significant impact on their impedance. In general, wider and thicker traces have lower impedance, while narrower and thinner traces have higher impedance. The spacing between traces also affects impedance, with closer spacing resulting in higher capacitance and lower impedance.

Dielectric Material

The dielectric constant (εr) of the PCB material is another important factor that affects impedance. Materials with higher dielectric constants, such as FR-4, have lower impedance compared to materials with lower dielectric constants, such as Rogers 4003. The thickness of the dielectric material also influences impedance, with thicker dielectrics resulting in higher impedance.

Frequency

The frequency of the signal passing through a PCB trace can also affect its impedance. At higher frequencies, the capacitive and inductive effects become more pronounced, leading to changes in impedance. It is important to consider the operating frequency range when designing PCBs for high-speed applications.

PCB Impedance Control Techniques

To ensure proper impedance matching and signal integrity in high-speed PCBs, several techniques can be employed during the design and manufacturing process.

Trace Geometry Optimization

One of the most effective ways to control PCB impedance is by optimizing the geometry of the traces. This involves adjusting the width, thickness, and spacing of traces to achieve the desired impedance values. PCB design software tools often include impedance calculators that can help designers determine the optimal trace geometries for a given impedance target.

Dielectric Material Selection

Choosing the appropriate dielectric material is another important factor in controlling PCB impedance. Different materials have varying dielectric constants, which can significantly affect the impedance of the traces. For high-speed applications, materials with lower dielectric constants, such as Rogers 4003 or Isola I-Tera, are often preferred due to their superior electrical properties.

Impedance Matching Techniques

Impedance matching techniques, such as termination and matching networks, can be used to ensure proper impedance matching between PCB traces and connected devices. Termination involves adding resistors at the end of a trace to match its impedance to the characteristic impedance of the transmission line. Matching networks, such as T-networks and Pi-networks, can be used to transform the impedance of a trace to match the impedance of the connected device.

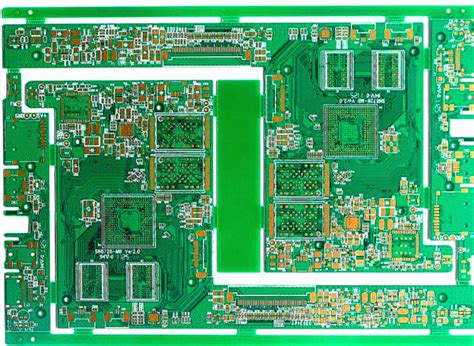

Manufacturing Process Control

Controlling the manufacturing process is essential for achieving consistent and accurate PCB impedance. This involves ensuring that the PCB fabrication parameters, such as copper plating thickness, dielectric thickness, and etching process, are tightly controlled and monitored. Impedance testing should be performed on manufactured PCBs to verify that the actual impedance values match the designed values.

Examples of PCB Impedance Calculation

To illustrate the use of PCB impedance formulas, let’s consider a few examples:

Example 1: Characteristic Impedance

Suppose we have a PCB trace with the following parameters:

– Dielectric constant (εr) = 4.5

– Height of the dielectric (h) = 0.2 mm

– Width of the trace (w) = 0.3 mm

– Thickness of the trace (t) = 0.035 mm

Using the characteristic impedance formula:

Z0 = 87 / √(4.5 + 1.41) * ln(5.98 * 0.2 / (0.8 * 0.3 + 0.035))

= 50.8 Ω

Example 2: Differential Impedance

Now, let’s calculate the differential impedance for a pair of traces with the following parameters:

– Characteristic impedance (Z0) = 50.8 Ω (from Example 1)

– Spacing between the traces (s) = 0.2 mm

– Height of the dielectric (h) = 0.2 mm

Using the differential impedance formula:

Zdiff = 2 * 50.8 * (1 – 0.48 * e^(-0.96 * 0.2 / 0.2))

= 93.3 Ω

These examples demonstrate how PCB impedance formulas can be used to calculate characteristic and differential impedances based on the physical properties of the PCB traces and dielectric material.

PCB Impedance Calculator Tools

To simplify the process of calculating PCB impedance, various tools and software packages are available that can automate the calculations and provide accurate results. Some popular PCB impedance calculator tools include:

-

Saturn PCB Toolkit: This free online tool allows users to calculate characteristic impedance, differential impedance, and other PCB-RElated parameters by entering the trace geometry and dielectric properties.

-

EEWeb PCB Impedance Calculator: This online calculator provides a user-friendly interface for calculating characteristic impedance and differential impedance based on trace geometry and dielectric properties.

-

Altium Designer: This professional PCB design software includes a built-in impedance calculator that can automatically calculate and optimize trace geometries for a given impedance target.

-

Polar Instruments Si9000e: This dedicated impedance test system offers high-accuracy impedance measurements and can be used to verify the impedance of manufactured PCBs.

Using these tools can greatly simplify the process of calculating and controlling PCB impedance, enabling designers to create high-quality, high-speed PCBs with optimal signal integrity and performance.

Frequently Asked Questions (FAQ)

-

Q: Why is PCB impedance important in high-speed designs?

A: PCB impedance is crucial in high-speed designs because mismatched impedances can lead to signal reflections, crosstalk, and other issues that can degrade signal integrity and system performance. Properly controlling PCB impedance ensures reliable and efficient operation of high-speed electronic circuits. -

Q: What is the difference between characteristic impedance and differential impedance?

A: Characteristic impedance (Z0) is the impedance of a single PCB trace, while differential impedance (Zdiff) is the impedance between two paired traces used for differential signaling. Characteristic impedance is important for maintaining signal integrity in single-ended circuits, while differential impedance is essential for maintaining signal balance and reducing EMI in differential circuits. -

Q: How does the dielectric material affect PCB impedance?

A: The dielectric constant (εr) of the PCB material is a key factor that affects impedance. Materials with higher dielectric constants, such as FR-4, have lower impedance compared to materials with lower dielectric constants, such as Rogers 4003. The thickness of the dielectric material also influences impedance, with thicker dielectrics resulting in higher impedance. -

Q: Can PCB impedance be measured after manufacturing?

A: Yes, PCB impedance can be measured after manufacturing using specialized impedance test equipment, such as the Polar Instruments Si9000e. Impedance testing is important for verifying that the actual impedance values of the manufactured PCB match the designed values and ensuring proper impedance control. -

Q: What are some common techniques for controlling PCB impedance?

A: Common techniques for controlling PCB impedance include trace geometry optimization (adjusting trace width, thickness, and spacing), dielectric material selection (choosing materials with suitable dielectric constants), impedance matching techniques (using termination and matching networks), and manufacturing process control (tightly controlling and monitoring PCB fabrication parameters).

| Factor | Effect on Impedance |

|---|---|

| Trace Width | Wider traces have lower impedance |

| Trace Thickness | Thicker traces have lower impedance |

| Dielectric Constant | Higher dielectric constants result in lower impedance |

| Dielectric Thickness | Thicker dielectrics result in higher impedance |

| Trace Spacing | Closer spacing results in higher capacitance and lower impedance |

| Frequency | Higher frequencies lead to more pronounced capacitive and inductive effects |

By understanding the factors that affect PCB impedance and employing appropriate design and manufacturing techniques, engineers can create high-speed PCBs with optimal signal integrity and performance. The use of PCB impedance calculators and simulation tools can greatly simplify the process of designing and verifying impedance-controlled PCBs, enabling the development of advanced electronic systems across a wide range of industries.

No responses yet