Introduction to PCB Reverse Engineering

Printed Circuit Board (PCB) reverse engineering, also known as PCB-RE, is the process of analyzing an existing PCB to understand its design, functionality, and components. This technique is widely used in various fields, such as electronics manufacturing, hardware security, and competitive analysis. By reverse engineering a PCB, engineers and researchers can gain valuable insights into the board’s layout, components, and potential vulnerabilities.

In this article, we will explore the use of cam editors in the PCB reverse engineering process, discussing their features, benefits, and applications. We will also delve into the techniques and tools used in PCB-RE and provide a step-by-step guide to reverse engineering a PCB using a cam editor.

What is a Cam Editor?

A cam editor, short for computer-aided manufacturing editor, is a software tool used in the design and manufacturing of PCBs. It allows users to create, edit, and manipulate the data required for the manufacturing process, such as drill files, Gerber files, and pick-and-place files.

Cam editors play a crucial role in PCB reverse engineering, as they enable users to import and analyze the data obtained from an existing PCB. By using a cam editor, engineers can reconstruct the PCB’s layout, identify components, and extract valuable information about the board’s design and functionality.

Benefits of Using a Cam Editor in PCB-RE

Using a cam editor in the PCB reverse engineering process offers several benefits, including:

-

Accurate data extraction: Cam editors can accurately extract the PCB’s layout, component placement, and routing information from the imported data, ensuring a high level of precision in the reverse engineering process.

-

Efficient analysis: With the help of a cam editor, engineers can quickly analyze the PCB’s design, identify potential issues, and make necessary modifications, saving time and resources.

-

Comprehensive visualization: Cam editors provide a visual representation of the PCB’s layout, allowing users to easily navigate and understand the board’s structure and components.

-

Integration with other tools: Many cam editors offer integration with other PCB design and analysis tools, enabling a seamless workflow and facilitating the exchange of data between different software.

PCB Reverse Engineering Techniques

There are several techniques used in PCB reverse engineering, each with its own advantages and limitations. Some of the most common techniques include:

Visual Inspection

Visual inspection is the process of examining the PCB using the naked eye or with the help of magnification tools, such as microscopes or digital cameras. This technique allows engineers to identify the board’s components, trace the connections, and detect any visible defects or modifications.

X-Ray Imaging

X-ray imaging is a non-destructive technique that uses X-rays to create a detailed image of the PCB’s internal structure. This method is particularly useful for analyzing multi-layer boards or identifying hidden components and connections.

Electrical Testing

Electrical testing involves measuring the electrical properties of the PCB’s components and connections using various tools, such as multimeters, oscilloscopes, and logic analyzers. This technique helps engineers understand the board’s functionality and detect any potential issues or vulnerabilities.

Desoldering and Reverse Engineering

Desoldering is the process of removing components from the PCB to gain access to the board’s internal layers and traces. Once the components are removed, engineers can use various techniques, such as microscopy or chemical etching, to analyze the board’s structure and extract valuable information.

Tools Used in PCB-RE

In addition to cam editors, several other tools are commonly used in PCB reverse engineering, including:

| Tool | Description |

|---|---|

| Microscopes | Optical and digital microscopes are used for close-up visual inspection of the PCB’s components and traces. |

| X-Ray Systems | X-ray imaging systems create detailed images of the PCB’s internal structure, revealing hidden components and connections. |

| Multimeters | Multimeters measure various electrical properties, such as voltage, current, and resistance, helping engineers understand the board’s functionality. |

| Oscilloscopes | Oscilloscopes display and analyze the waveforms of electrical signals, allowing engineers to identify potential issues or vulnerabilities. |

| Logic Analyzers | Logic analyzers capture and display digital signals, enabling engineers to debug and reverse engineer complex digital circuits. |

| Desoldering Tools | Desoldering tools, such as hot air stations and desoldering pumps, are used to remove components from the PCB for further analysis. |

Step-by-Step Guide to Reverse Engineering a PCB Using a Cam Editor

-

Obtain the PCB: Acquire the PCB you want to reverse engineer. Ensure that you have the necessary permissions and legal rights to perform the reverse engineering process.

-

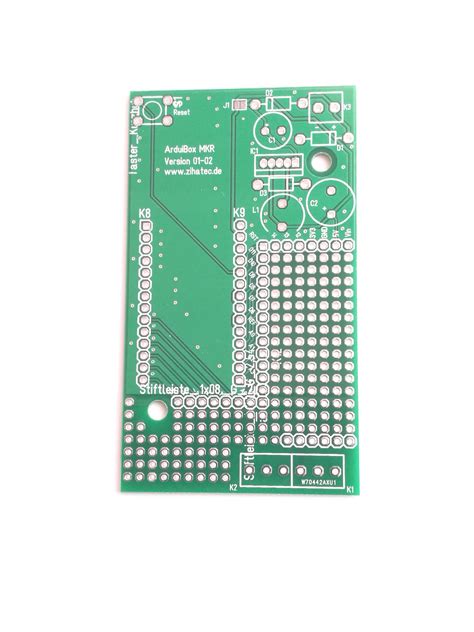

Capture PCB Data: Use a scanner or digital camera to capture high-resolution images of both sides of the PCB. If available, obtain the Gerber files or other manufacturing data associated with the board.

-

Import Data into Cam Editor: Import the captured images and/or manufacturing data into your cam editor software. Most cam editors support a wide range of file formats, such as Gerber, ODB++, and IPC-2581.

-

Align and Calibrate: Align the imported images and calibrate the scale to ensure accurate measurements and component placement.

-

Trace the PCB Layout: Use the cam editor’s tools to trace the PCB’s layout, including the board outline, component footprints, and trace routing. Many cam editors offer automated tracing features that can significantly speed up this process.

-

Identify Components: Analyze the PCB’s components using the cam editor’s built-in libraries or by manually comparing the footprints with known component packages. Create a bill of materials (BOM) listing all the identified components.

-

Reconstruct Schematic: Based on the traced layout and identified components, reconstruct the PCB’s schematic using the cam editor’s schematic capture tools or by exporting the data to a dedicated schematic design software.

-

Analyze and Verify: Thoroughly analyze the reconstructed PCB design, checking for any discrepancies, design rule violations, or potential issues. Verify the functionality of the reconstructed schematic through simulation or by comparing it with the original PCB’s behavior.

-

Document and Report: Create detailed documentation of the reverse engineered PCB, including the reconstructed schematic, BOM, and any relevant findings or observations. Generate reports or data packages that can be shared with stakeholders or used for further analysis.

Applications of PCB Reverse Engineering

PCB reverse engineering has numerous applications across various industries, such as:

Electronics Manufacturing

PCB-RE is often used in electronics manufacturing to analyze and improve existing designs, identify potential issues, and ensure compatibility with new components or manufacturing processes.

Hardware Security

In the field of hardware security, PCB reverse engineering is employed to identify potential vulnerabilities, detect counterfeit components, and assess the overall security of electronic devices.

Competitive Analysis

Companies may use PCB-RE to analyze competitors’ products, understand their design choices, and gain insights into their manufacturing processes, ultimately helping them improve their own products and stay competitive in the market.

Obsolescence Management

When dealing with obsolete or legacy electronic systems, PCB reverse engineering can be used to recreate the design files and documentation necessary for maintaining, repairing, or upgrading these systems.

Education and Research

PCB-RE is also used in educational and research settings to teach students about PCB design, manufacturing, and analysis techniques, as well as to explore new design methodologies and technologies.

Frequently Asked Questions (FAQ)

1. Is PCB reverse engineering legal?

The legality of PCB reverse engineering depends on various factors, such as the jurisdiction, the purpose of the reverse engineering, and any applicable contracts or agreements. In many cases, reverse engineering for the purpose of interoperability, research, or education is considered legal, provided that it does not infringe upon any intellectual property rights or violate any laws or regulations.

2. How accurate is PCB reverse engineering using a cam editor?

The accuracy of PCB reverse engineering using a cam editor depends on several factors, such as the quality of the captured data, the complexity of the PCB, and the skill of the engineer performing the reverse engineering. However, with high-quality data and a skilled engineer, cam editors can produce highly accurate reconstructions of PCB designs.

3. Can a cam editor reverse engineer multi-layer PCBs?

Yes, cam editors can reverse engineer multi-layer PCBs, provided that the necessary data for each layer is available. This may require additional techniques, such as X-ray imaging or layer-by-layer delamination, to capture the data for the internal layers.

4. How long does it take to reverse engineer a PCB using a cam editor?

The time required to reverse engineer a PCB using a cam editor varies depending on the complexity of the board, the quality of the captured data, and the experience of the engineer. Simple boards may take a few hours, while more complex designs can take several days or even weeks.

5. Are there any automated tools for PCB reverse engineering?

Yes, there are several automated tools and software packages that can assist in the PCB reverse engineering process, such as automated image stitching, component recognition, and netlist extraction. However, these tools often require manual intervention and verification to ensure the accuracy of the results.

Conclusion

Cam editors play a vital role in the PCB reverse engineering process, enabling engineers to accurately reconstruct PCB designs, identify components, and extract valuable information about the board’s functionality and potential vulnerabilities. By understanding the techniques, tools, and applications of PCB-RE, engineers can leverage this powerful methodology to improve electronics manufacturing, hardware security, and competitive analysis.

As the complexity of electronic devices continues to increase, the importance of PCB reverse engineering will only grow, making it an essential skill for engineers and researchers in the field. By staying up-to-date with the latest tools and techniques, such as cam editors, professionals can effectively navigate the challenges of PCB-RE and unlock the full potential of this valuable methodology.

No responses yet