What is a PCB File?

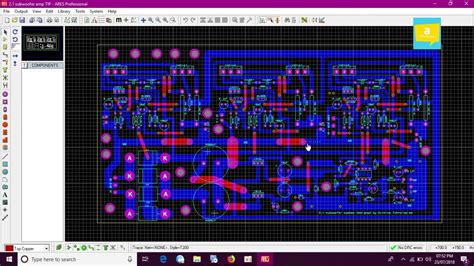

A PCB file, short for Printed Circuit Board file, is a digital document that contains all the necessary information required to manufacture a printed circuit board. It includes the layout of the board, the components used, their placement, and the connections between them. PCB files are essential for the production of electronic devices, as they provide a blueprint for the manufacturer to follow.

Types of PCB Files

There are several types of PCB files, each with its own purpose and format. Some of the most common types include:

-

Gerber Files: These are the most widely used PCB files and are considered the industry standard. Gerber files contain information about the copper layers, solder mask, silkscreen, and drill holes of the PCB.

-

ODB++ Files: ODB++ (Open Database++) is a more modern and comprehensive format that includes not only the PCB layout but also the component information and the bill of materials (BOM).

-

IPC-2581 Files: This is a newer format that aims to replace Gerber and ODB++ files. It includes all the necessary information for PCB manufacturing in a single file.

-

Eagle Files: These are proprietary files used by the Eagle PCB design software. They contain the schematic and layout information of the PCB.

-

Altium Files: Similar to Eagle files, Altium files are proprietary to the Altium Designer software and contain the PCB design information.

| File Type | Extension | Description |

|---|---|---|

| Gerber | .gbr | Industry standard for PCB manufacturing |

| ODB++ | .tgz | Comprehensive format including BOM |

| IPC-2581 | .xml | Newer format aiming to replace Gerber and ODB++ |

| Eagle | .brd | Proprietary format for Eagle PCB design software |

| Altium | .pcbdoc | Proprietary format for Altium Designer software |

Why High Availability is Important for PCB Files

High availability is crucial for PCB files because they are the foundation of the manufacturing process. If a PCB file is lost, corrupted, or inaccessible, it can lead to significant delays in production, increased costs, and even the complete failure of the project. Ensuring high availability of PCB files is essential for several reasons:

-

Preventing Manufacturing Delays: If a PCB file is not available when needed, it can halt the entire manufacturing process. This can lead to missed deadlines, unhappy clients, and financial losses.

-

Enabling Quick Iterations: In many cases, PCB designs go through multiple iterations before the final version is approved. Having high availability of PCB files allows for quick and easy access to previous versions, enabling faster iterations and improvements.

-

Facilitating Collaboration: PCB design often involves multiple team members, including designers, engineers, and manufacturers. High availability of PCB files ensures that all stakeholders can access the latest version of the design, reducing the risk of miscommunication and errors.

-

Ensuring Disaster Recovery: In the event of a catastrophic failure, such as a hardware malfunction or a natural disaster, having highly available PCB files ensures that the design can be quickly recovered and production can resume with minimal downtime.

Strategies for Ensuring High Availability of PCB Files

There are several strategies that can be implemented to ensure high availability of PCB files:

1. Version Control Systems

Version control systems (VCS) are software tools that help manage changes to files over time. They allow multiple users to collaborate on the same project, track changes, and revert to previous versions if necessary. Some popular VCS for PCB design include:

-

Git: A distributed VCS that is widely used in software development but can also be used for PCB design. Git allows for branching, merging, and remote collaboration.

-

SVN (Subversion): A centralized VCS that is simple to use and has been around for a long time. SVN is well-suited for small to medium-sized projects.

-

Perforce: A hybrid VCS that combines the benefits of centralized and distributed systems. Perforce is known for its scalability and performance.

Using a VCS ensures that PCB files are always accessible, even if a single user’s computer fails. It also allows for easy collaboration and tracking of changes over time.

2. Cloud Storage

Cloud storage is another effective strategy for ensuring high availability of PCB files. By storing files in the cloud, they can be accessed from anywhere with an internet connection, reducing the risk of data loss due to hardware failure or other localized issues.

There are many cloud storage providers to choose from, such as:

-

Google Drive: Offers 15GB of free storage and integrates well with other Google services.

-

Dropbox: Provides easy file sharing and collaboration features, with 2GB of free storage.

-

OneDrive: Microsoft’s cloud storage solution, offering 5GB of free storage and integration with Office 365.

-

AWS S3: Amazon’s scalable and durable object storage service, well-suited for large-scale projects.

When using cloud storage, it’s important to ensure that files are regularly backed up and that access controls are in place to prevent unauthorized modifications.

3. Redundant Storage

Redundant storage involves keeping multiple copies of PCB files in different locations, such as on different servers or in different geographic regions. This ensures that if one copy becomes inaccessible, there are other copies available to fall back on.

Some common redundant storage configurations include:

-

RAID (Redundant Array of Independent Disks): A technique that combines multiple physical drives into a single logical unit for improved performance and fault tolerance.

-

Mirroring: Creating an exact copy of data on a separate storage device, providing a backup in case the primary device fails.

-

Offsite Backup: Storing copies of PCB files in a different geographic location, such as a remote data center, to protect against localized disasters.

Redundant storage can be implemented using a combination of hardware and software solutions, such as network-attached storage (NAS) devices and backup software.

4. Access Controls and Permissions

Ensuring high availability of PCB files also involves implementing proper access controls and permissions. This means granting access only to authorized users and restricting permissions based on user roles and responsibilities.

Some best practices for access control include:

- Using strong, unique passwords for each user account.

- Implementing multi-factor authentication (MFA) for an additional layer of security.

- Regularly reviewing and updating user permissions to ensure they align with current roles and responsibilities.

- Logging and monitoring access to PCB files to detect and respond to unauthorized activity.

By implementing these access control measures, organizations can reduce the risk of accidental or malicious changes to PCB files, ensuring their integrity and availability.

Best Practices for Managing PCB Files

In addition to the strategies mentioned above, there are several best practices that organizations can follow to ensure high availability and effective management of PCB files:

-

Standardize File Formats: Establish a standard file format for PCB design, such as Gerber or ODB++, to ensure compatibility and ease of sharing among team members and with manufacturers.

-

Use Descriptive File Names: Adopt a consistent and descriptive naming convention for PCB files, including the project name, version number, and date. This makes it easier to identify and locate specific files when needed.

-

Maintain Comprehensive Documentation: Keep detailed documentation of PCB designs, including schematics, bill of materials (BOM), and assembly instructions. This documentation should be stored alongside the PCB files and kept up-to-date with any changes.

-

Regularly Backup Files: Implement a regular backup schedule for PCB files, ensuring that multiple copies are kept in different locations. This can be automated using backup software or scripts.

-

Conduct Design Reviews: Perform regular design reviews to catch any errors or inconsistencies early in the process. This can involve peer reviews, automated design rule checks (DRC), and collaboration with manufacturers.

-

Train Team Members: Provide training to team members on the proper use of version control systems, cloud storage, and other tools used for managing PCB files. Ensure that everyone understands their roles and responsibilities in maintaining high availability.

By following these best practices, organizations can streamline their PCB design process, reduce the risk of errors and delays, and ultimately ensure the successful production of their electronic devices.

Frequently Asked Questions (FAQ)

-

What is the most widely used PCB file format?

The most widely used PCB file format is Gerber. Gerber files contain information about the copper layers, solder mask, silkscreen, and drill holes of the PCB and are considered the industry standard for PCB manufacturing. -

How can version control systems help ensure high availability of PCB files?

Version control systems help ensure high availability of PCB files by allowing multiple users to collaborate on the same project, track changes, and revert to previous versions if necessary. This ensures that PCB files are always accessible, even if a single user’s computer fails. -

What are some popular cloud storage providers for storing PCB files?

Some popular cloud storage providers for storing PCB files include Google Drive, Dropbox, OneDrive, and AWS S3. These providers offer various amounts of free storage and have different features for file sharing and collaboration. -

What is redundant storage, and how does it contribute to high availability?

Redundant storage involves keeping multiple copies of PCB files in different locations, such as on different servers or in different geographic regions. This ensures that if one copy becomes inaccessible, there are other copies available to fall back on, thus contributing to high availability. -

Why is it important to implement access controls and permissions for PCB files?

Implementing access controls and permissions for PCB files is important because it ensures that only authorized users can access and modify the files. This reduces the risk of accidental or malicious changes to PCB files, maintaining their integrity and availability.

In conclusion, ensuring high availability of PCB files is crucial for the success of any electronic device manufacturing project. By implementing strategies such as version control systems, cloud storage, redundant storage, and access controls, organizations can protect their PCB files from loss, corruption, and unauthorized changes. Additionally, following best practices for managing PCB files, such as standardizing file formats, using descriptive file names, and conducting regular design reviews, can further streamline the design process and reduce the risk of errors and delays. By prioritizing the high availability of PCB files, organizations can ensure the smooth and successful production of their electronic devices.

No responses yet