Introduction to PCBLive

PCBLive is a comprehensive event that focuses on the latest trends, technologies, and best practices in printed circuit board (PCB) design and manufacturing. This annual event brings together industry experts, designers, engineers, and manufacturers from around the world to share their knowledge and experience in the field of PCB development.

What is PCB Design?

PCB design is the process of creating a layout for a printed circuit board that will be used to interconnect electronic components. The design process involves several steps, including:

- Schematic capture

- Component placement

- Routing

- Design rule checks (DRCs)

- Generation of manufacturing files

Schematic Capture

Schematic capture is the first step in PCB design. It involves creating a diagram that represents the electrical connections between components. This diagram, known as a schematic, uses standardized symbols to represent components and lines to represent the connections between them.

Component Placement

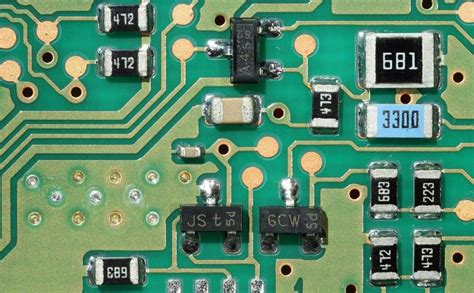

Once the schematic is complete, the next step is to place the components on the PCB layout. This process involves determining the optimal location for each component based on factors such as signal integrity, power distribution, and mechanical constraints.

Routing

After the components are placed, the next step is to route the connections between them. This process involves creating copper traces on the PCB that electrically connect the components according to the schematic. Routing can be done manually or using automated tools.

Design Rule Checks (DRCs)

Design rule checks are used to verify that the PCB layout meets the manufacturing constraints and design rules specified by the PCB fabricator. These checks help to ensure that the PCB can be manufactured reliably and at a reasonable cost.

Generation of Manufacturing Files

Once the PCB layout is complete and has passed the DRCs, the final step is to generate the manufacturing files. These files include the Gerber files, which are used to create the photomasks for the PCB Layers, and the drill files, which are used to create the holes for through-hole components and vias.

PCB Manufacturing Process

The PCB manufacturing process involves several steps, including:

- PCB Fabrication

- PCB Assembly

- Testing and inspection

PCB Fabrication

PCB fabrication is the process of creating the bare PCB from the manufacturing files generated during the design process. This process typically involves the following steps:

- Creating the photomasks for each layer of the PCB

- Applying photoresist to the copper-clad laminate

- Exposing the photoresist to UV light through the photomasks

- Developing the photoresist to remove the unexposed areas

- Etching away the unwanted copper

- Drilling holes for through-hole components and vias

- Applying solder mask and silkscreen

PCB Assembly

PCB assembly is the process of populating the bare PCB with components. This process can be done manually or using automated equipment, depending on the complexity of the PCB and the volume of production. The assembly process typically involves the following steps:

- Applying solder paste to the PCB pads

- Placing the components on the PCB

- Reflowing the solder to create electrical connections

- Cleaning the PCB to remove any residual flux

Testing and Inspection

After the PCB is assembled, it undergoes various tests and inspections to ensure that it functions as intended and meets the required quality standards. These tests may include:

- Automated optical inspection (AOI)

- X-ray inspection

- In-circuit testing (ICT)

- Functional testing

PCBLive Event Highlights

Keynote Speakers

PCBLive features keynote speakers from leading companies in the PCB industry. These speakers share their insights and experiences on topics such as:

- Advancements in PCB design software

- New materials and manufacturing processes

- Challenges and opportunities in the PCB industry

- Future trends in PCB design and manufacturing

| Speaker | Company | Topic |

|---|---|---|

| John Smith | ABC Design Software | Advancements in PCB Design Automation |

| Jane Doe | XYZ PCB Manufacturer | Innovative PCB Manufacturing Techniques |

| Bob Johnson | 123 Electronics | Future of PCB Design and Manufacturing |

Technical Sessions

PCBLive offers a wide range of technical sessions that cover various aspects of PCB design and manufacturing. These sessions are presented by industry experts and provide attendees with practical knowledge and skills that they can apply in their work. Some of the topics covered in the technical sessions include:

- High-speed PCB design techniques

- PCB Stackup design and material selection

- Signal and power integrity analysis

- Design for manufacturing (DFM) best practices

- Flexible and Rigid-Flex PCB design

- Thermal management in PCB design

Exhibition Hall

The PCBLive exhibition hall features booths from leading PCB design software vendors, PCB manufacturers, and component suppliers. Attendees can visit these booths to learn about the latest products and services, get hands-on demonstrations, and network with industry professionals.

Some of the companies exhibiting at PCBLive include:

- Altium

- Cadence

- Mentor Graphics

- Zuken

- Isola

- Rogers Corporation

- Cirexx International

- Sierra Circuits

Networking Opportunities

PCBLive provides numerous opportunities for attendees to network with their peers and industry experts. These opportunities include:

- Welcome reception

- Lunch and coffee breaks

- Evening social events

- Designated networking areas in the exhibition hall

PCBLive Design Competition

One of the highlights of PCBLive is the annual PCB design competition. This competition challenges designers to create innovative and original PCB designs based on a specific set of requirements. The winning designs are selected by a panel of industry experts and are recognized during the event’s award ceremony.

The design competition categories may include:

- Best high-speed digital design

- Best analog/mixed-signal design

- Best flex or rigid-flex design

- Best design for manufacturability

- Best student design

Benefits of Attending PCBLive

Attending PCBLive offers numerous benefits for PCB designers, engineers, and manufacturers, including:

- Learning about the latest trends and technologies in PCB design and manufacturing

- Gaining practical knowledge and skills through technical sessions and workshops

- Networking with industry professionals and peers

- Discovering new products and services from leading vendors

- Participating in the PCB design competition and showcasing design skills

Conclusion

PCBLive is a must-attend event for anyone involved in PCB design and manufacturing. The event provides a unique opportunity to learn, network, and stay up-to-date with the latest developments in the industry. By attending PCBLive, designers, engineers, and manufacturers can gain valuable knowledge and skills that will help them to create better, more reliable, and more cost-effective PCBs.

Frequently Asked Questions (FAQ)

-

Who should attend PCBLive?

PCBLive is designed for PCB designers, electrical engineers, manufacturing professionals, and anyone involved in the PCB industry who wants to stay up-to-date with the latest trends and technologies. -

How often is PCBLive held?

PCBLive is an annual event, typically held in the spring or summer. -

What is the format of PCBLive?

PCBLive is a multi-day event that includes keynote speeches, technical sessions, workshops, an exhibition hall, and networking events. -

How can I register for PCBLive?

Registration for PCBLive can be done online through the event’s website. Early bird discounts are usually available for those who register in advance. -

Are there any special hotel rates available for PCBLive attendees?

Yes, PCBLive often partners with local hotels to offer special rates for attendees. Information about hotel accommodations can be found on the event’s website.

No responses yet