Introduction to PCB Uncertainty and Random Number Generators

Printed circuit board (PCB) design often requires a level of intentional uncertainty or randomness to improve performance, reduce electromagnetic interference (EMI), or meet other design goals. One effective way to introduce this uncertainty is through the use of random number generators (RNGs) during the PCB design process. RNGs can be used to randomize various aspects of the PCB layout, such as trace widths, spacings, and component placements, resulting in a more robust and reliable design.

In this article, we will explore the concept of PCB uncertainty, the benefits of incorporating randomness in PCB design, and how to effectively use random number generators to achieve these goals. We will also discuss different types of RNGs, their implementation in PCB design software, and best practices for applying randomness to your designs.

Benefits of Incorporating Uncertainty in PCB Design

Incorporating uncertainty in PCB design offers several benefits, including:

-

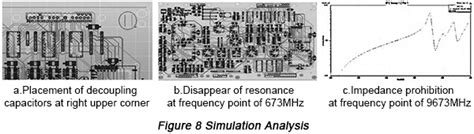

Reduced EMI: By randomizing trace widths, spacings, and routing paths, you can minimize the coupling of electromagnetic fields between traces, reducing overall EMI.

-

Improved signal integrity: Randomizing trace parameters helps to prevent resonances and standing waves, which can degrade signal quality.

-

Enhanced manufacturability: Introducing controlled randomness in your design can help to distribute manufacturing tolerances more evenly, leading to higher yields and lower production costs.

-

Increased design flexibility: RNGs allow you to explore a wider range of design options and fine-tune your PCB layout for optimal performance.

Types of Random Number Generators for PCB Design

There are two main types of random number generators that can be used in PCB design:

-

Pseudo-random number generators (PRNGs): These algorithms generate sequences of numbers that appear random but are actually determined by a seed value. PRNGs are deterministic, meaning that given the same seed, they will always produce the same sequence of numbers. Examples of PRNGs include linear congruential generators and Mersenne Twister.

-

True random number generators (TRNGs): These devices generate random numbers based on physical processes, such as atmospheric noise or radioactive decay. TRNGs are non-deterministic and provide higher quality randomness compared to PRNGs. However, they are more complex to implement and may not be necessary for most PCB design applications.

For PCB design purposes, pseudo-random number generators are typically sufficient and more practical to implement within design software.

Implementing Random Number Generators in PCB Design Software

Most modern PCB design software packages, such as Altium Designer, KiCad, and Eagle, support the use of scripting or programming languages that allow you to implement random number generators. These languages may include Python, Lua, or the software’s proprietary scripting language.

Here’s an example of how to generate a random number using Python:

import random

# Generate a random float between 0 and 1

random_float = random.random()

# Generate a random integer between 1 and 10

random_int = random.randint(1, 10)

To apply randomness to your PCB design, you can create scripts that modify various design parameters based on the generated random numbers. For example, you could create a script that randomizes the widths of selected traces within a specified range:

import random

# Select traces to randomize

traces_to_randomize = ["TRACE1", "TRACE2", "TRACE3"]

# Set minimum and maximum trace widths (in mm)

min_width = 0.1

max_width = 0.5

# Randomize trace widths

for trace in traces_to_randomize:

random_width = random.uniform(min_width, max_width)

set_trace_width(trace, random_width)

Best Practices for Applying Randomness in PCB Design

When applying randomness to your PCB designs, consider the following best practices:

-

Define clear goals: Identify the specific aspects of your design that you want to optimize through randomization, such as EMI reduction or signal integrity improvement.

-

Set appropriate constraints: Determine the acceptable range of randomization for each design parameter to ensure that your PCB remains manufacturable and functional.

-

Test and validate: Run simulations and perform physical tests to verify that the randomized design meets your performance goals and does not introduce any unintended issues.

-

Document your process: Keep detailed records of the randomization techniques used, the constraints applied, and the results obtained to ensure reproducibility and facilitate future design iterations.

Examples of Applying Randomness in PCB Design

Here are a few examples of how randomness can be applied to different aspects of PCB design:

Trace Widths and Spacings

By randomizing trace widths and spacings within a specified range, you can reduce EMI and improve signal integrity. This technique is particularly useful for high-speed digital designs or designs with sensitive analog circuits.

| Parameter | Minimum | Maximum |

|---|---|---|

| Trace Width | 0.1 mm | 0.5 mm |

| Trace Spacing | 0.2 mm | 0.8 mm |

Component Placement

Randomizing the placement of components on your PCB can help to distribute heat more evenly and minimize the impact of manufacturing tolerances. This can be achieved by applying small random offsets to the component positions within a defined area.

| Parameter | Minimum | Maximum |

|---|---|---|

| X-offset | -0.5 mm | 0.5 mm |

| Y-offset | -0.5 mm | 0.5 mm |

Via Placement and Sizes

Randomizing the placement and sizes of vias can help to reduce EMI and improve the reliability of your PCB. By varying the via sizes and positions within acceptable limits, you can create a more robust design that is less sensitive to manufacturing variations.

| Parameter | Minimum | Maximum |

|---|---|---|

| Via Diameter | 0.3 mm | 0.7 mm |

| Via Spacing | 0.5 mm | 1.0 mm |

Frequently Asked Questions (FAQ)

-

Q: Can I use random number generators for every aspect of my PCB design?

A: While random number generators can be useful for optimizing certain aspects of your PCB design, they should be applied selectively and with caution. Some design parameters, such as component footprints and critical dimensions, should not be randomized to ensure proper functionality and manufacturability. -

Q: How do I determine the appropriate range of randomization for each design parameter?

A: The appropriate range of randomization depends on factors such as the specific design requirements, manufacturing capabilities, and industry standards. Consult with your manufacturer and refer to relevant design guidelines to determine the acceptable limits for each parameter. -

Q: Will using random number generators in my PCB design increase the cost or time of manufacturing?

A: In most cases, incorporating randomness in your PCB design should not significantly impact the cost or time of manufacturing, as long as the randomization is applied within acceptable limits. However, it’s always a good idea to discuss your design approach with your manufacturer to ensure compatibility with their processes. -

Q: Can I use random number generators to optimize the performance of analog circuits?

A: Yes, random number generators can be used to optimize certain aspects of analog circuit design, such as component placement and routing. However, the specific techniques and constraints applied may differ from those used in digital designs, and a deeper understanding of analog circuit behavior is required. -

Q: Are there any open-source tools or libraries available for implementing random number generators in PCB design software?

A: Yes, there are several open-source tools and libraries that can be used to incorporate random number generators into PCB design workflows. For example, the Python-based KiCad scripting API allows you to access and modify design parameters using Python’s built-in random number generation functions. Similarly, the open-source PCB design software gEDA includes a Scheme-based scripting interface that supports random number generation. Additionally, many PCB design software packages support the use of external libraries or modules, such as the Python NumPy library, which provides a wide range of random number generation capabilities.

Conclusion

Incorporating uncertainty through the use of random number generators can be a powerful technique for optimizing the performance, reliability, and manufacturability of your PCB designs. By selectively randomizing design parameters such as trace widths, component placements, and via sizes, you can reduce EMI, improve signal integrity, and create more robust designs that are less sensitive to manufacturing variations.

When applying randomness to your PCB designs, it’s essential to set clear goals, define appropriate constraints, and thoroughly test and validate the results. By following best practices and collaborating with your manufacturer, you can harness the power of randomness to create high-quality, reliable PCBs that meet your specific design requirements.

As PCB Design Challenges continue to evolve, the use of random number generators and other advanced optimization techniques will become increasingly important. By staying up-to-date with the latest tools, techniques, and best practices, you can ensure that your PCB designs remain at the forefront of innovation and performance.

No responses yet