What is a PCB Legend?

A PCB (Printed Circuit Board) legend, also known as silkscreen or overlay, is the text and symbols printed on the surface of a PCB. The legend provides important information about the components, their placement, and the overall functionality of the board. It helps in the assembly, testing, and troubleshooting of the PCB.

The PCB legend typically includes:

– Component identifiers (e.g., R1, C2, U3)

– Component values (e.g., 10K, 0.1uF, 74HC00)

– Polarity markers (e.g., + and – signs)

– Test points

– Company logos and product names

– Revision numbers and manufacturing dates

Importance of PCB Legends

PCB legends play a crucial role in the manufacturing and assembly process of electronic devices. They provide the following benefits:

-

Ease of Assembly: The legend helps the assembly team identify the correct placement of components on the board, reducing the chances of errors and improving the overall quality of the assembled product.

-

Simplified Troubleshooting: In case of any issues with the assembled board, the legend makes it easier for technicians to identify and replace faulty components, saving time and effort.

-

Enhanced Communication: The legend acts as a visual guide for all stakeholders involved in the PCB Manufacturing process, ensuring clear communication and reducing the chances of misinterpretation.

-

Improved Aesthetics: A well-designed PCB legend can enhance the overall appearance of the board, making it look more professional and visually appealing.

PCB Legend Printing Techniques

There are several techniques used for printing PCB legends, each with its own advantages and disadvantages. The choice of technique depends on factors such as the desired durability, cost, and the complexity of the design.

1. Silk Screening

Silk screening is the most common method for printing PCB legends. It involves using a fine mesh screen and a stencil to apply ink onto the surface of the PCB. The process is as follows:

- A stencil with the desired legend design is created.

- The stencil is placed on top of the mesh screen.

- Ink is pushed through the mesh screen onto the PCB surface using a squeegee.

- The ink is cured using heat or UV light.

Advantages:

– Cost-effective for large production runs

– Durable and long-lasting

– Wide range of ink colors available

Disadvantages:

– Not suitable for fine details or small text

– Requires a separate stencil for each design

– Time-consuming setup process

2. Direct Legend Printing

Direct legend printing involves using an inkjet printer to print the legend directly onto the PCB surface. This method is suitable for low-volume production runs and prototyping.

Advantages:

– Quick and easy setup

– Suitable for small production runs and prototyping

– Allows for fine details and small text

Disadvantages:

– Limited durability compared to silk screening

– Higher cost per unit for large production runs

– Limited color options

3. Laser Marking

Laser marking uses a high-powered laser to etch the legend onto the PCB surface. This method is suitable for high-density designs and applications that require high durability.

Advantages:

– Permanent and highly durable

– Suitable for fine details and small text

– Fast and efficient process

Disadvantages:

– Higher initial equipment cost

– Limited color options (typically black or white)

– May cause slight damage to the PCB surface

Designing PCB Legends

When designing PCB legends, there are several factors to consider to ensure readability, clarity, and overall effectiveness.

1. Font Selection

Choose a font that is easy to read and suitable for the intended application. Some commonly used fonts for PCB legends include:

- Arial

- Helvetica

- Verdana

- Tahoma

Avoid using decorative or overly stylized fonts, as they can be difficult to read and may not translate well during the printing process.

2. Text Size

Ensure that the text size is appropriate for the available space on the PCB and is easily readable. The minimum recommended text height for PCB legends is 0.8mm (0.031 inches), but larger sizes are often preferred for improved readability.

3. Line Width

The line width of the legend text should be sufficient to ensure good visibility and durability. A minimum line width of 0.15mm (0.006 inches) is recommended, but thicker lines may be necessary for larger text or high-wear applications.

4. Color Contrast

Choose colors that provide good contrast against the PCB Substrate to ensure optimal readability. White or yellow legends on a green or black substrate are common choices for good contrast.

5. Placement

Position the legend text and symbols in a way that does not interfere with the components or the assembly process. Ensure adequate clearance around the legend to avoid any potential issues during soldering or other manufacturing steps.

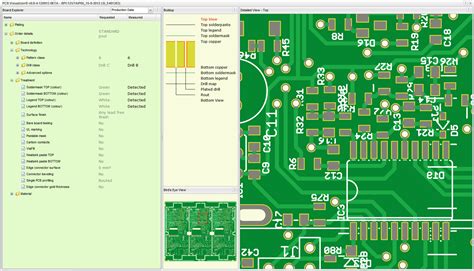

PCB Legend File Preparation

To prepare your PCB legend design for printing, follow these steps:

- Create your legend design using PCB Design Software (e.g., Altium Designer, Eagle, KiCad).

- Ensure that the legend is on a separate layer from the other PCB elements (e.g., copper traces, solder mask).

- Convert the legend layer to a vector format (e.g., DXF, SVG, or Gerber) for compatibility with the printing process.

- Verify that the legend file meets the requirements of your chosen printing technique (e.g., minimum line width, text size).

- Send the legend file along with the other PCB Files to your manufacturer for production.

Frequently Asked Questions (FAQ)

1. What is the minimum text size for PCB legends?

The minimum recommended text height for PCB legends is 0.8mm (0.031 inches), but larger sizes are often preferred for improved readability.

2. What colors are best for PCB legends?

White or yellow legends on a green or black substrate are common choices for good contrast and readability.

3. Can I use any font for my PCB legend?

While you can use any font, it’s best to choose a font that is easy to read and suitable for the intended application. Avoid using decorative or overly stylized fonts, as they can be difficult to read and may not translate well during the printing process.

4. How do I prepare my PCB legend design for printing?

To prepare your PCB legend design for printing, create the design using PCB design software, ensure that the legend is on a separate layer, convert the legend layer to a vector format, verify that the file meets the requirements of your chosen printing technique, and send the file to your manufacturer along with the other PCB files.

5. What are the most common PCB legend printing techniques?

The most common PCB legend printing techniques are silk screening, direct legend printing, and laser marking. Each method has its own advantages and disadvantages, and the choice depends on factors such as the desired durability, cost, and the complexity of the design.

| Printing Technique | Advantages | Disadvantages |

|---|---|---|

| Silk Screening | – Cost-effective for large runs – Durable – Wide color range |

– Not suitable for fine details – Requires separate stencil – Time-consuming setup |

| Direct Legend | – Quick setup – Suitable for small runs and prototyping – Allows fine details |

– Limited durability – Higher cost per unit for large runs – Limited colors |

| Laser Marking | – Permanent and durable – Suitable for fine details – Fast process |

– Higher initial equipment cost – Limited colors (black or white) – May slightly damage PCB surface |

By following the guidelines and best practices outlined in this article, you can create effective and professional-looking PCB legends that enhance the overall quality and functionality of your electronic devices. Remember to consider factors such as font selection, text size, line width, color contrast, and placement when designing your legends, and choose the appropriate printing technique based on your specific requirements and constraints.

No responses yet