What is a Thermoelectric Generator?

A thermoelectric generator is a solid-state device that converts a temperature difference directly into electrical energy. It consists of two dissimilar semiconductors, typically n-type and p-type, connected electrically in series and thermally in parallel. When one side of the TEG is heated and the other side is cooled, electrons flow from the hot side to the cold side, generating an electric current.

The efficiency of a thermoelectric generator depends on several factors, including the temperature difference, the properties of the semiconductors, and the thermal conductivity of the materials used. Although TEGs have relatively low efficiency compared to other power generation technologies, they have several advantages, such as:

- No moving parts, which makes them reliable and maintenance-free

- Silent operation

- Scalability, as they can be used in small or large applications

- Ability to generate electricity from waste heat

The Seebeck Effect: The Working Principle of Thermoelectric Generators

The Seebeck effect is the fundamental principle behind thermoelectric generators. It states that when two dissimilar conductors or semiconductors are connected to form a closed circuit and the junctions are maintained at different temperatures, an electric current will flow through the circuit.

In a thermoelectric generator, the two dissimilar semiconductors are typically n-type and p-type materials. N-type semiconductors have an excess of electrons, while p-type semiconductors have an excess of holes (positively charged particles). When heat is applied to one side of the TEG, electrons in the n-type material and holes in the p-type material move from the hot side to the cold side, generating an electric current.

The magnitude of the electric current generated by a TEG depends on the Seebeck coefficient, which is a measure of the voltage generated per unit temperature difference. The Seebeck coefficient varies for different materials and is usually given in units of microvolts per Kelvin (μV/K).

Some common thermoelectric materials and their Seebeck coefficients are:

| Material | Seebeck Coefficient (μV/K) |

|---|---|

| Bismuth Telluride (Bi2Te3) | 200-250 |

| Lead Telluride (PbTe) | 200-300 |

| Silicon Germanium (SiGe) | 150-200 |

| Skutterudites | 150-200 |

Designing a DIY Thermoelectric Generator

To design a DIY thermoelectric generator, you need to consider several factors:

-

Thermoelectric materials: Choose appropriate n-type and p-type semiconductors with high Seebeck coefficients and low thermal conductivity. Bismuth telluride (Bi2Te3) is a common choice for DIY projects due to its availability and good performance at room temperature.

-

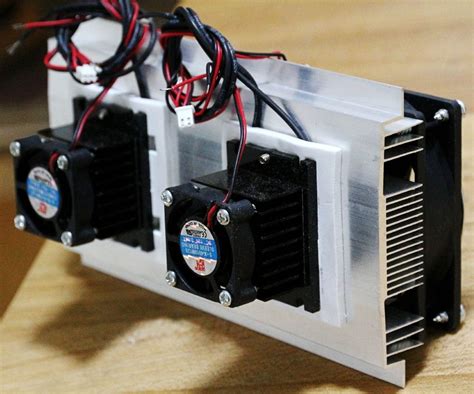

Heat source and heat sink: Identify a suitable heat source, such as a candle, a hot plate, or waste heat from an engine. The heat source should be able to maintain a stable temperature difference across the TEG. You also need a heat sink to dissipate heat from the cold side of the TEG, such as a finned aluminum heatsink or a water-cooled block.

-

Electrical connections: Connect the n-type and p-type semiconductors electrically in series using copper electrodes. Ensure good electrical contact between the semiconductors and the electrodes to minimize resistance.

-

Thermal insulation: Use thermal insulation materials, such as ceramic plates or fiberglass, to minimize heat loss and maintain a stable temperature difference across the TEG.

-

Load matching: Match the electrical load (e.g., a resistor or an LED) to the internal resistance of the TEG to maximize power output. The optimal load resistance is equal to the internal resistance of the TEG.

Step-by-Step Guide to Making a DIY Thermoelectric Generator

Materials and Tools Required

- Bismuth telluride (Bi2Te3) thermoelectric modules (e.g., TEC1-12706)

- Copper electrodes (e.g., copper foil or copper wire)

- Thermal insulation materials (e.g., ceramic plates or fiberglass)

- Heat source (e.g., candle or hot plate)

- Heat sink (e.g., finned aluminum heatsink or water-cooled block)

- Electrical load (e.g., resistor or LED)

- Soldering iron and solder

- Multimeter

- Thermal Adhesive or thermal grease

- Screwdriver and pliers

Assembly Steps

-

Prepare the thermoelectric modules: If using commercial Bi2Te3 modules, clean the surfaces with isopropyl alcohol to remove any dirt or oxidation.

-

Attach the copper electrodes: Using a soldering iron, solder the copper electrodes to the n-type and p-type sides of the thermoelectric modules. Ensure good electrical contact and mechanical stability.

-

Apply thermal insulation: Place the thermal insulation materials between the thermoelectric modules and the heat source/heat sink. Use thermal adhesive or thermal grease to ensure good thermal contact.

-

Assemble the generator: Arrange the thermoelectric modules and insulation materials between the heat source and heat sink. Use screws or clamps to secure the assembly and ensure good thermal contact.

-

Connect the electrical load: Solder the electrical load (e.g., resistor or LED) to the copper electrodes. Use a multimeter to measure the voltage and current output of the generator.

-

Test the generator: Apply heat to the heat source and monitor the temperature difference across the thermoelectric modules. Measure the voltage and current output of the generator using the multimeter. Adjust the load resistance to maximize power output.

Advantages and Limitations of DIY Thermoelectric Generators

Advantages

- Easy to build using readily available materials

- No moving parts, which makes them reliable and maintenance-free

- Silent operation

- Scalable, as multiple modules can be connected in series or parallel to increase power output

- Can generate electricity from waste heat

Limitations

- Low efficiency (typically 5-10%) compared to other power generation technologies

- Requires a consistent and sufficient temperature difference to generate useful power

- Limited power output (usually in the milliwatt to watt range) depending on the size and number of thermoelectric modules used

- Relatively expensive thermoelectric materials (e.g., bismuth telluride) compared to other semiconductors

Potential Applications of DIY Thermoelectric Generators

- Charging small electronic devices (e.g., smartphones, cameras) using waste heat from a campfire or stove

- Powering remote sensors or monitoring devices in industrial or automotive settings

- Supplementing solar or wind power systems for off-grid applications

- Educational projects to demonstrate the Seebeck effect and thermoelectric power generation

Frequently Asked Questions (FAQ)

-

What is the typical efficiency of a DIY thermoelectric generator?

A: The efficiency of a DIY thermoelectric generator is typically around 5-10%, depending on the materials used, the temperature difference, and the design of the generator. Commercial thermoelectric generators can achieve efficiencies of up to 15-20% under optimal conditions. -

How much power can a DIY thermoelectric generator produce?

A: The power output of a DIY thermoelectric generator depends on the size and number of thermoelectric modules used, as well as the temperature difference across the modules. A single Bi2Te3 module (e.g., TEC1-12706) can generate around 2-5 watts of power with a temperature difference of 100°C. By connecting multiple modules in series or parallel, the power output can be increased. -

Can a DIY thermoelectric generator be used to power a household?

A: No, a DIY thermoelectric generator is not suitable for powering a household due to its low power output and efficiency. Thermoelectric generators are better suited for small-scale applications where waste heat is readily available, such as in remote sensing or portable electronic devices. -

What is the best heat source for a DIY thermoelectric generator?

A: The best heat source for a DIY thermoelectric generator is one that can provide a stable and sufficient temperature difference across the thermoelectric modules. Some common heat sources include candles, hot plates, and waste heat from engines or industrial processes. The heat source should be chosen based on the desired power output and the available temperature difference. -

How can I improve the efficiency of my DIY thermoelectric generator?

A: To improve the efficiency of your DIY thermoelectric generator, you can: - Use thermoelectric materials with higher Seebeck coefficients and lower thermal conductivity

- Minimize heat loss by using effective thermal insulation materials

- Ensure good thermal contact between the thermoelectric modules and the heat source/heat sink

- Match the electrical load to the internal resistance of the generator to maximize power output

- Maintain a stable and sufficient temperature difference across the thermoelectric modules

Conclusion

DIY thermoelectric generators are an interesting and educational way to explore the Seebeck effect and generate electricity from waste heat. Although they have relatively low efficiency and power output compared to other power generation technologies, they offer several advantages, such as reliability, silent operation, and scalability.

By following the step-by-step guide provided in this article, you can build your own DIY thermoelectric generator using readily available materials and tools. With further optimization and experimentation, you can improve the performance of your generator and adapt it to various applications.

As research into thermoelectric materials and device design continues, we can expect to see more efficient and powerful thermoelectric generators in the future. These devices have the potential to play a significant role in waste heat recovery and sustainable energy generation, contributing to a more energy-efficient and environmentally friendly world.

No responses yet