Introduction to Resistor Types

Resistors are essential components in electronic circuits that limit or regulate the flow of electrical current. They come in various types, each with unique characteristics suitable for different applications. Two common types of resistors are carbon film resistors and metal film resistors. In this article, we will explore the differences between these two resistor types and help you understand how to distinguish them.

What is a Carbon Film Resistor?

Carbon film resistors are made by depositing a thin layer of carbon onto a ceramic substrate. The resistance value is determined by the thickness and composition of the carbon film. These resistors are known for their low cost and general-purpose usage in electronic circuits.

Characteristics of Carbon Film Resistors

- Composition: Carbon film deposited on a ceramic substrate

- Tolerance: Typically ±5% or ±10%

- Temperature Coefficient: Usually around ±250 to ±500 ppm/°C

- Noise: Relatively higher than metal film resistors

- Power Rating: Generally lower than metal film resistors

- Frequency Response: Limited due to higher parasitic capacitance

- Cost: Inexpensive compared to metal film resistors

What is a Metal Film Resistor?

Metal film resistors are constructed by depositing a thin layer of metal alloy onto a ceramic substrate. The resistance value is determined by the thickness and composition of the metal film. These resistors offer better precision, stability, and performance compared to carbon film resistors.

Characteristics of Metal Film Resistors

- Composition: Metal alloy film deposited on a ceramic substrate

- Tolerance: Typically ±0.1%, ±0.5%, ±1%, or ±2%

- Temperature Coefficient: Usually around ±50 to ±100 ppm/°C

- Noise: Lower than carbon film resistors

- Power Rating: Generally higher than carbon film resistors

- Frequency Response: Better due to lower parasitic capacitance

- Cost: More expensive than carbon film resistors

Differences Between Carbon Film and Metal Film Resistors

Now that we have a basic understanding of carbon film and metal film resistors, let’s compare their key differences:

| Characteristic | Carbon Film Resistor | Metal Film Resistor |

|---|---|---|

| Composition | Carbon film | Metal alloy film |

| Tolerance | ±5% or ±10% | ±0.1% to ±2% |

| Temperature Coefficient | ±250 to ±500 ppm/°C | ±50 to ±100 ppm/°C |

| Noise | Higher | Lower |

| Power Rating | Lower | Higher |

| Frequency Response | Limited | Better |

| Cost | Inexpensive | More expensive |

Tolerance

Tolerance is the allowed deviation from the nominal resistance value. Carbon film resistors typically have a tolerance of ±5% or ±10%, while metal film resistors offer tighter tolerances ranging from ±0.1% to ±2%. This means that metal film resistors provide more precise resistance values compared to carbon film resistors.

Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature variations. Carbon film resistors have a higher temperature coefficient, usually around ±250 to ±500 ppm/°C (parts per million per degree Celsius). In contrast, metal film resistors have a lower temperature coefficient, typically around ±50 to ±100 ppm/°C. This means that metal film resistors maintain more stable resistance values across a wider temperature range.

Noise

Noise refers to the unwanted electrical fluctuations that can affect the performance of a resistor. Carbon film resistors tend to have higher noise levels compared to metal film resistors. This is due to the granular nature of the carbon film, which can cause microscopic variations in resistance. Metal film resistors, on the other hand, have a more uniform and homogeneous film, resulting in lower noise levels.

Power Rating

The power rating indicates the maximum amount of power a resistor can dissipate without being damaged. Carbon film resistors generally have lower power ratings compared to metal film resistors. This means that metal film resistors can handle higher power levels and are more suitable for applications that require higher power dissipation.

Frequency Response

Frequency response refers to how well a resistor performs at different frequencies. Carbon film resistors have limited frequency response due to their higher parasitic capacitance. This means that they may not be suitable for high-frequency applications. Metal film resistors, on the other hand, have lower parasitic capacitance and offer better frequency response, making them more suitable for high-frequency circuits.

Cost

Cost is an important factor when selecting resistors for a project. Carbon film resistors are generally less expensive compared to metal film resistors. This makes them a popular choice for general-purpose applications where high precision and performance are not critical. Metal film resistors, being more precise and stable, come at a higher cost.

How to Identify Carbon Film and Metal Film Resistors

Now that we know the differences between carbon film and metal film resistors, let’s explore how to identify them visually.

Visual Appearance

- Carbon Film Resistors:

- Usually have a dark brown or black body color

- The color bands indicating the resistance value and tolerance are printed on the body

-

May have a glossy or matte finish

-

Metal Film Resistors:

- Typically have a blue or green body color

- The color bands indicating the resistance value and tolerance are printed on the body

- Often have a smooth, glossy finish

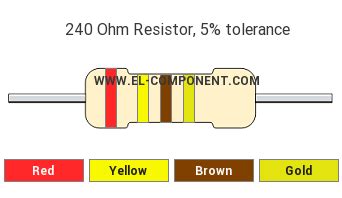

Color Code

Both carbon film and metal film resistors use a standardized color code to indicate their resistance value and tolerance. The color code consists of four or five color bands, each representing a specific digit or multiplier.

| Color | Digit | Multiplier | Tolerance |

|---|---|---|---|

| Black | 0 | 1 | – |

| Brown | 1 | 10 | ±1% |

| Red | 2 | 100 | ±2% |

| Orange | 3 | 1,000 | – |

| Yellow | 4 | 10,000 | – |

| Green | 5 | 100,000 | ±0.5% |

| Blue | 6 | 1,000,000 | ±0.25% |

| Violet | 7 | 10,000,000 | ±0.1% |

| Gray | 8 | 100,000,000 | ±0.05% |

| White | 9 | 1,000,000,000 | – |

| Gold | – | 0.1 | ±5% |

| Silver | – | 0.01 | ±10% |

To read the color code, start from the band closest to one end of the resistor. The first two bands represent the first two digits of the resistance value, the third band is the multiplier, and the fourth band (if present) indicates the tolerance. If there is a fifth band, it represents the temperature coefficient.

For example, if a resistor has the color bands: Yellow, Violet, Orange, Gold, it would have a resistance value of 47,000 ohms (47 kΩ) with a tolerance of ±5%.

Applications of Carbon Film and Metal Film Resistors

Carbon film and metal film resistors find applications in various electronic circuits. Here are some common use cases:

Carbon Film Resistors

- General-purpose circuits

- Low-power applications

- Voltage dividers

- Pull-up and pull-down resistors

- Filtering and coupling circuits

Metal Film Resistors

- Precision circuits

- Instrumentation and measurement equipment

- Audio and video equipment

- High-frequency circuits

- Telecommunications equipment

- Medical devices

- Aerospace and military applications

Frequently Asked Questions (FAQ)

-

Q: Can I replace a carbon film resistor with a metal film resistor?

A: In most cases, yes. However, you should consider the specific requirements of your circuit, such as tolerance, temperature stability, and noise. Metal film resistors generally offer better performance, but they come at a higher cost. -

Q: What happens if I use a resistor with a higher power rating than needed?

A: Using a resistor with a higher power rating than required is generally safe. It will not affect the functionality of the circuit. However, using a resistor with a lower power rating than needed can cause the resistor to overheat and potentially fail. -

Q: How do I choose the right tolerance for my application?

A: The choice of tolerance depends on the specific requirements of your circuit. If your application requires high precision, you should opt for resistors with tighter tolerances, such as ±0.1% or ±0.5%. For general-purpose applications, tolerances of ±5% or ±10% may suffice. -

Q: Are there any other types of resistors besides carbon film and metal film?

A: Yes, there are several other types of resistors, including wire-wound resistors, thick film resistors, thin film resistors, and surface mount resistors (SMD). Each type has its own unique characteristics and applications. -

Q: Can I measure the resistance value of a resistor using a multimeter?

A: Yes, you can use a multimeter to measure the resistance value of a resistor. Set the multimeter to the resistance mode (usually denoted by the ohm symbol: Ω) and connect the probes to the resistor leads. The multimeter will display the resistance value.

Conclusion

In conclusion, carbon film resistors and metal film resistors are two common types of resistors used in electronic circuits. While they serve the same basic purpose of limiting or regulating current flow, they have distinct characteristics that make them suitable for different applications.

Carbon film resistors are inexpensive and widely used in general-purpose circuits where high precision and performance are not critical. They have a higher temperature coefficient, higher noise levels, and lower power ratings compared to metal film resistors.

On the other hand, metal film resistors offer better precision, stability, and performance. They have tighter tolerances, lower temperature coefficients, lower noise levels, and higher power ratings. However, they come at a higher cost compared to carbon film resistors.

When selecting resistors for your project, consider the specific requirements of your circuit, such as tolerance, temperature stability, noise, power rating, and frequency response. Choose the appropriate resistor type based on these factors and your budget constraints.

By understanding the differences between carbon film and metal film resistors, you can make informed decisions when designing and building electronic circuits. Remember to always refer to the color code to determine the resistance value and tolerance of your resistors.

No responses yet