Introduction to PCB routing

Printed circuit board (PCB) design is a complex process that involves multiple steps, from schematic capture to component placement to routing the connections between components. PCB routing, in particular, is a critical step that determines the functionality, reliability, and manufacturability of the final board.

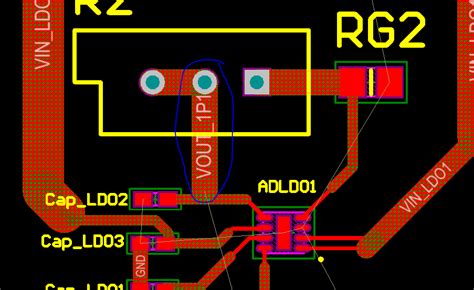

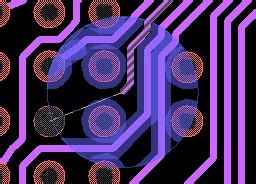

PCB routing refers to the process of creating the conductive paths or traces that electrically connect the various components on a PCB. The goal is to route these traces in the most efficient way possible while adhering to design rules and constraints such as trace width, spacing, via size, etc.

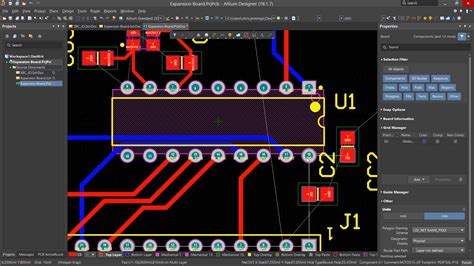

Traditionally, PCB routing was done by hand, with designers manually drawing each trace one by one. However, with the increasing complexity of modern PCB designs, manual routing has become increasingly time-consuming and error-prone. This has led to the development of automated routing tools that can quickly and accurately route large numbers of traces based on predefined rules and constraints.

Despite the advantages of automated routing, some designers still prefer to route their boards by hand, believing that it gives them more control and flexibility. In this article, we will explore the pros and cons of hand routing versus using an automated router, and make the case for why auto interactive routing is the ideal solution for most PCB design projects.

The Challenges of Hand Routing

Hand routing a PCB involves manually drawing each trace using CAD software, following the schematic and component placement. The designer must carefully consider factors such as trace width, spacing, via placement, and signal integrity while trying to minimize the overall board size and layer count.

While hand routing can give designers more control over the final layout, it also has several significant drawbacks:

-

Time-consuming: Hand routing a complex board with hundreds or thousands of traces can take days or even weeks, depending on the designer’s skill level and the project’s complexity.

-

Error-prone: With so many traces to route, it’s easy for designers to make mistakes such as crossing traces, violating spacing rules, or creating signal integrity issues. These errors can be difficult to catch and even harder to fix.

-

Inconsistent results: Different designers may route the same board differently based on their individual skills, preferences, and experience level. This can lead to inconsistent results and make it harder to maintain and update the design in the future.

-

Limited scalability: As PCB designs become more complex, with higher component densities and more layers, hand routing becomes increasingly impractical. It’s simply not feasible for a human designer to route thousands of traces while considering all the necessary design rules and constraints.

The Advantages of Automated Routing

Automated PCB routing tools use algorithms to quickly and accurately route traces based on predefined design rules and constraints. These tools can route a complex board in a matter of hours or even minutes, compared to the days or weeks required for hand routing.

Some of the key advantages of automated routing include:

-

Speed: Automated routers can complete the routing process much faster than a human designer, even for complex boards with thousands of traces.

-

Accuracy: Automated routers follow predefined design rules and constraints, ensuring that all traces are routed correctly and consistently. This reduces the risk of errors and improves the overall quality of the final board.

-

Consistency: Automated routers produce consistent results every time, regardless of the designer’s skill level or experience. This makes it easier to maintain and update the design in the future.

-

Optimization: Automated routers can optimize the routing process to minimize board size, layer count, and overall cost. They can also perform complex tasks such as differential pair routing and high-speed signal routing that would be difficult or impossible to do by hand.

Despite these advantages, automated routing is not a perfect solution. One of the main drawbacks is that it can sometimes produce sub-optimal results, particularly for complex or unconventional designs. Automated routers may also struggle with certain design rules or constraints that are difficult to define mathematically.

The Case for Auto Interactive Routing

Auto interactive routing is a hybrid approach that combines the speed and accuracy of automated routing with the flexibility and control of hand routing. With auto interactive routing, the designer can define the basic routing strategy and constraints, and then let the automated router do the bulk of the work. The designer can then review the results and make manual adjustments as needed to fine-tune the final layout.

Some of the key benefits of auto interactive routing include:

-

Efficiency: Auto interactive routing is much faster than hand routing, but still allows the designer to maintain control over the final layout. This makes it an efficient solution for most PCB design projects.

-

Flexibility: Auto interactive routing gives designers the flexibility to define their own routing strategies and constraints, and to make manual adjustments as needed. This allows for more creative and unconventional designs that may not be possible with fully automated routing.

-

Collaboration: Auto interactive routing makes it easier for multiple designers to collaborate on a project, since the basic routing strategy and constraints can be defined upfront and then shared among the team.

-

Continuous improvement: Auto interactive routing tools are constantly evolving, with new features and capabilities being added all the time. This means that designers can take advantage of the latest advancements in routing technology without having to completely relearn their tools and workflows.

Choosing the Right Routing Approach for Your Project

When deciding between hand routing, automated routing, and auto interactive routing, it’s important to consider the specific needs and constraints of your project. Factors to consider include:

- Complexity of the design

- Size and layer count of the board

- Required turnaround time

- Available resources and budget

- Skill level and experience of the design team

In general, hand routing is best suited for simple designs with a small number of traces, or for projects where the designer needs complete control over every aspect of the layout. Automated routing is ideal for complex designs with a large number of traces, or for projects where speed and consistency are the top priorities.

Auto interactive routing is the best choice for most projects, as it combines the benefits of both hand routing and automated routing in a flexible and efficient workflow. By defining the basic routing strategy and constraints upfront, and then letting the automated router do the bulk of the work, designers can achieve high-quality results in a fraction of the time required for hand routing.

| Routing Approach | Advantages | Disadvantages |

|---|---|---|

| Hand Routing | Complete control over layout, Suitable for simple designs | Time-consuming, Error-prone, Inconsistent results, Limited scalability |

| Automated Routing | Fast, Accurate, Consistent, Optimized | Sub-optimal results for complex designs, Limited flexibility |

| Auto Interactive Routing | Efficient, Flexible, Collaborative, Continuously improving | Requires some setup and manual adjustment |

Best Practices for Auto Interactive Routing

To get the most out of auto interactive routing, there are several best practices that designers should follow:

-

Define clear routing strategies and constraints: Before starting the routing process, take the time to define clear strategies and constraints based on the specific requirements of your project. This includes factors such as trace width and spacing, via size and placement, layer assignment, and signal integrity rules.

-

Use a hierarchical approach: For complex designs, it’s often helpful to use a hierarchical approach that breaks the board down into smaller, more manageable sections. Route each section independently, and then merge them together to create the final layout.

-

Take advantage of design rule checks: Most auto interactive routing tools include built-in design rule checks (DRCs) that can catch errors and violations before they become a problem. Make sure to run DRCs regularly throughout the routing process to ensure that your design is error-free.

-

Communicate with your manufacturing partner: Before finalizing your design, it’s important to communicate with your manufacturing partner to ensure that it meets their specific requirements and capabilities. This can help you avoid costly mistakes and delays down the line.

Frequently Asked Questions (FAQ)

- What is the difference between hand routing and automated routing?

- Hand routing involves manually drawing each trace using CAD software, while automated routing uses algorithms to quickly and accurately route traces based on predefined design rules and constraints.

- What are the advantages of auto interactive routing?

- Auto interactive routing combines the speed and accuracy of automated routing with the flexibility and control of hand routing, making it an efficient solution for most PCB design projects.

- How do I choose the right routing approach for my project?

- When choosing a routing approach, consider factors such as the complexity of the design, the size and layer count of the board, the required turnaround time, and the available resources and budget.

- What are some best practices for auto interactive routing?

- Best practices for auto interactive routing include defining clear routing strategies and constraints, using a hierarchical approach for complex designs, taking advantage of design rule checks, and communicating with your manufacturing partner.

- Can auto interactive routing completely replace hand routing?

- While auto interactive routing can handle the majority of routing tasks, there may still be situations where hand routing is necessary, such as for unconventional or highly specialized designs. The best approach is to use auto interactive routing as a starting point, and then make manual adjustments as needed to fine-tune the final layout.

Conclusion

PCB routing is a critical step in the PCB design process that can have a significant impact on the functionality, reliability, and manufacturability of the final board. While hand routing and automated routing both have their strengths and weaknesses, auto interactive routing offers the best of both worlds by combining the speed and accuracy of automation with the flexibility and control of manual routing.

By following best practices such as defining clear routing strategies and constraints, using a hierarchical approach, and taking advantage of design rule checks, designers can use auto interactive routing to create high-quality PCB layouts in a fraction of the time required for hand routing. As PCB designs continue to become more complex and demanding, auto interactive routing will become an increasingly essential tool for designers looking to stay competitive and deliver the best possible results for their clients.

No responses yet