Understanding Resistor Materials

Resistors are passive two-terminal electrical components that implement electrical resistance as a circuit element. Their primary purpose is to reduce current flow and lower voltage levels within circuits. Resistors can be made from a variety of materials, each with distinct properties:

Carbon Composition Resistors

- Made of carbon powder mixed with a binder

- Inexpensive but have poor tolerance and stability

- Suitable for general purpose applications

Carbon Film Resistors

- Thin carbon film on a ceramic rod

- Better tolerance and temperature stability vs carbon composition

- Commonly used in consumer electronics

Metal Film Resistors

- Thin metal film on a ceramic rod

- Superior tolerance, temperature stability, and reliability

- Used in precision circuits and harsh environments

Wirewound Resistors

- Metallic wire wrapped around an insulating core

- Handle high power/current levels

- Expensive specialty resistors for niche uses

For most modern electronics, the choice usually comes down to carbon film vs metal film resistors. Let’s compare them head-to-head.

Carbon Film vs Metal Film Resistors

Manufacturing Process

Carbon film resistors are made by depositing a thin layer of pyrolytic carbon onto a ceramic substrate rod. The film is spiral cut to increase the resistive path. Terminals are attached and the entire assembly is coated with an insulating lacquer.

Metal film resistors are manufactured similarly, but using metal alloys like nichrome instead of carbon. The metal is vaporized in a vacuum chamber and deposited onto the ceramic rod. Nickel-chromium alloys are popular due to their resistivity and stability properties.

Tolerance

Tolerance refers to how close the actual resistance is to the specified nominal value. It’s expressed as a +/- percentage.

Carbon film typical tolerances:

– ± 5%

– ± 2%

Metal film typical tolerances:

– ± 1%

– ± 0.5%

– ± 0.1%

– ± 0.05% (precision)

Metal film resistors offer tighter tolerances, an important advantage for applications sensitive to resistance fluctuation. The better tolerance of metal films allows for more precise circuit behavior.

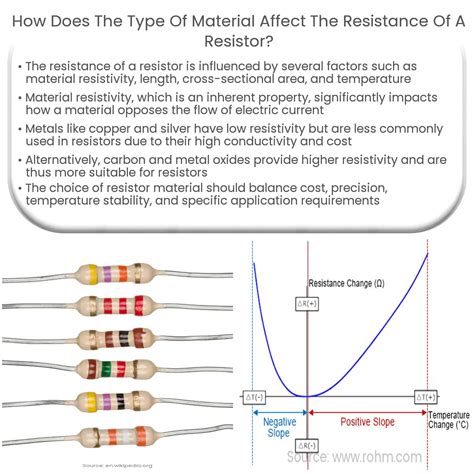

Temperature Coefficient

The temperature coefficient of resistance (TCR) quantifies how much the resistance value changes with temperature variation. It’s measured in ppm/°C (parts per million per degree Celsius).

| Resistor Material | Typical TCR (ppm/°C) |

|---|---|

| Carbon Film | ± 200 to ± 500 |

| Metal Film | ± 50 to ± 100 |

Metal film resistors have significantly lower TCR values, meaning their resistance remains more stable over temperature ranges. This is critical in circuits that may be exposed to variable ambient temperatures.

Noise

Noise refers to unwanted AC voltage fluctuations across the resistor. It’s caused by random electron motion and imperfections in the resistive material. Noise is measured in μV/V (microvolts per volt).

Carbon film resistors have higher noise, around 0.1 to 0.5 μV/V. Metal film resistors exhibit much lower noise levels, as little as 0.05 μV/V. In sensitive analog circuits or audio applications, the lower noise of metal films provides superior signal quality.

Power Rating

The power rating indicates how much power the resistor can safely dissipate without damage. It’s specified in watts (W).

| Power Rating (W) | Carbon Film Size | Metal Film Size |

|---|---|---|

| 1/8 | 0204 | 0204 |

| 1/4 | 0207 | 0207 |

| 1/2 | 0309 | 0309 |

| 1 | 0414 | 0414 |

| 2 | 0617 | 0617 |

For a given power rating, carbon and metal film resistors are available in the same physical sizes. The choice between them depends more on the other performance factors.

Reliability

Metal film resistors are known for their high reliability and stability. They exhibit minimal drift in resistance value over time. The metal alloy films are more resistant to moisture and environmental factors compared to carbon.

Carbon film resistors are prone to drifting more over their service life. They absorb moisture which can change resistance. At high humidity, they may experience temporary noise bursts. The carbon film is also susceptible to mechanical damage.

For critical applications requiring a high degree of reliability, metal films are the preferred choice. They maintain their characteristics in harsh conditions.

Cost

Due to the materials used and precision manufacturing, metal film resistors are more expensive than carbon films. The exact price difference varies by tolerance and other specifications, but metal films can cost 2x to 5x more.

Carbon film remains a cost-effective option for less demanding circuits. When high volumes are needed and performance isn’t as critical, their lower price is attractive.

Choosing Between Carbon Film and Metal Film

With their individual strengths and weaknesses, which resistor material is the best choice? It depends on the specific requirements of the application.

When to Use Carbon Film Resistors

- General purpose circuits

- Non-critical resistance tolerance

- Low-cost designs

- Hobbyist projects

When to Use Metal Film Resistors

- Precision analog circuits

- Tight tolerance requirements

- Stable operation over temperature

- Low noise characteristics

- High reliability needs

- Professional equipment

Frequently Asked Questions

What are the resistance ranges of carbon and metal film resistors?

Both are commonly available from 1 ohm to 10 megaohm. Some precision metal films can go down to 0.1 ohm or up to 100 megaohm.

Are carbon and metal film resistors interchangeable?

Generally, a metal film resistor can directly replace a same-value carbon film type. However, the reverse is not always true, as the metal film may have been chosen for its superior specs. It’s best to replace resistors with ones of the same material.

Can carbon film resistors handle high voltages?

Carbon film resistors are limited to a few hundred volts due to their construction. For high voltage applications, you need specialized resistors with an extended creepage path, like metal oxide film types.

What is the shelf life of resistors?

When stored in a cool, dry environment, both carbon and metal film resistors can last many years. Proper storage conditions minimize drifting. Always check resistors that have been in long-term storage with an ohmmeter before using.

What about other resistor types like thick/thin film?

Thick and thin film resistors use newer technologies for precision networks and surface-mount packaging. They fulfill roles where discrete through-hole carbon/metal film styles aren’t suitable. The choice between thick and thin film depends on resistance range, TCR, and size requirements.

Ultimately, understanding the differences between carbon film and metal film resistors allows you to optimize your designs. By matching the component characteristics to the demands of the application, you’ll ensure your circuits perform up to expectations. Consider all the electrical, environmental, and budget factors when specifying resistor types.

With careful selection of carbon film, metal film, or other resistor technologies, you can build reliable electronics that stand the test of time. The humble resistor may seem simple, but knowing its subtleties makes all the difference in the final product. Choose your resistor materials wisely.

No responses yet