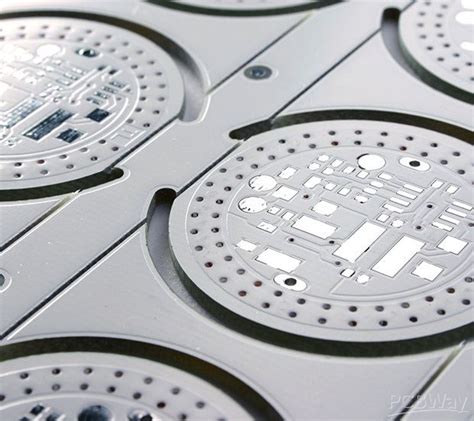

What is an Aluminum PCB?

An aluminum PCB, also known as a metal core PCB (MCPCB), uses an aluminum substrate or base layer instead of the traditional FR-4 material. The aluminum provides superior thermal conductivity compared to FR-4, allowing heat to dissipate more efficiently from high-power components. This makes Aluminum PCBs ideal for applications that generate a lot of heat such as LED lighting, motor drives, power supplies, and high-power amplifiers.

The typical structure of an aluminum PCB includes:

– Aluminum substrate (1-3mm thick)

– Thermal insulation layer

– Copper circuit layer

– Protective coating (solder mask)

Advantages of RAYMING Aluminum PCBs

1. Excellent Thermal Management

One of the main advantages of using an aluminum PCB is its ability to dissipate heat more effectively. RAYMING’s aluminum PCBs have a thermal conductivity of 1.0-2.5 W/m·K, which is about 8-10 times higher than FR-4. This allows heat to spread evenly across the board and prevents hot spots from forming around power components.

By keeping temperatures down, aluminum PCBs can help:

– Increase reliability and lifespan of components

– Improve energy efficiency

– Allow for higher power densities

– Eliminate the need for additional heat sinks

RAYMING offers a range of thermal management options for aluminum PCBs including:

| Option | Description | Thermal Conductivity (W/m·K) |

|---|---|---|

| Insulated Metal Substrate (IMS) | Dielectric layer laminated to aluminum base | 1.0-3.0 |

| Direct Bonded Copper (DBC) | Copper foil directly bonded to ceramic layer on aluminum | 24-180 |

| Active Metal Brazed (AMB) | Copper layer brazed to aluminum with no dielectric | 115-200 |

2. Mechanical Strength and Stability

Aluminum PCBs are more rigid and robust compared to traditional FR-4 PCBs. The aluminum substrate provides a strong backbone that resists bending, twisting, and vibrations. This makes aluminum PCBs suitable for applications that involve physical stress or harsh environments.

RAYMING’s aluminum PCBs offer:

– Thicknesses ranging from 1.0mm to 3.0mm

– Minimum bend radius of 10 times board thickness

– Withstand vibrations up to 20G

– Operating temperatures from -40°C to +180°C

3. Design Flexibility

RAYMING’s aluminum PCBs can be customized to fit various design requirements. Some of the options available include:

| Feature | Capability |

|---|---|

| Board Thickness | 1.0mm to 3.0mm |

| Copper Thickness | 1 oz to 10 oz |

| Minimum Hole Size | 0.2mm |

| Minimum Line Width/Spacing | 3/3mil (0.075/0.075mm) |

| Solder Mask | Any color with matte, glossy or textured finish |

| Silkscreen | Any color with optional carbon ink for LED |

| Surface Finish | HASL, OSP, ENIG, Immersion Silver/Tin |

| Castellated Holes | Plated half-holes for edge connections |

RAYMING also offers value-added services such as:

– Electrical testing

– Thermal simulations

– Design for manufacturing (DFM) review

– Assembly and sub-assembly

– Turnkey manufacturing

4. Cost-Effective Solution

While aluminum PCBs may have a higher raw material cost compared to FR-4, they can be a more cost-effective solution in the long run. By providing better thermal management and reliability, aluminum PCBs can help reduce overall system costs.

RAYMING offers competitive pricing for aluminum PCBs by:

– Optimizing design for manufacturing

– Minimizing material waste

– Leveraging high-volume production

– Providing turnkey and sub-assembly services

RAYMING’s Aluminum PCB Manufacturing Capabilities

RAYMING has state-of-the-art facilities and equipment to manufacture high-quality aluminum PCBs. Some of the key capabilities include:

1. Multilayer Aluminum PCBs

RAYMING can fabricate multilayer aluminum PCBs with up to 8 copper layers. The multilayer construction allows for more complex designs and higher component densities. The layers are laminated together using a high-temperature thermally conductive prepreg material.

| Capability | Specification |

|---|---|

| Number of Layers | Up to 8 |

| Insulation Material | High-Tg Thermally Conductive Prepreg |

| Minimum Hole Size | 0.2mm |

| Aspect Ratio | 8:1 |

| Copper Thickness | 1 oz to 6 oz |

2. Thick Copper Aluminum PCBs

For high-current applications, RAYMING offers aluminum PCBs with thick copper layers up to 10 oz (350µm). The thick copper allows for higher current carrying capacity and lower resistance. RAYMING uses an advanced electroplating process to achieve uniform copper thickness across the board.

3. High-Precision Laser Drilling

RAYMING uses high-precision laser drilling to create micro vias and fine holes in aluminum PCBs. The laser drilling process allows for smaller hole sizes and higher aspect ratios compared to mechanical drilling. This enables denser designs and better electrical performance.

| Capability | Specification |

|---|---|

| Minimum Hole Size | 0.1mm |

| Aspect Ratio | 10:1 |

| Positioning Accuracy | ±0.05mm |

4. Automated Optical Inspection (AOI)

To ensure the highest quality, RAYMING uses automated optical inspection (AOI) to check every aluminum PCB for defects such as:

– Short circuits

– Open circuits

– Incorrect hole sizes

– Copper thickness variations

– Solder mask defects

The AOI system uses high-resolution cameras and advanced image processing algorithms to detect defects as small as 0.05mm.

Applications of RAYMING Aluminum PCBs

RAYMING’s aluminum PCBs are used in a wide range of industries and applications including:

1. LED Lighting

Aluminum PCBs are widely used in LED lighting applications due to their excellent thermal management properties. They help keep the LED junction temperature low, which improves light output, color consistency, and lifespan. RAYMING’s aluminum PCBs are used in various LED lighting products such as:

– Street lights

– High bay lights

– Flood lights

– Grow lights

– Automotive lights

2. Power Electronics

Aluminum PCBs are ideal for power electronic applications that generate a lot of heat such as:

– Motor drives

– Inverters

– Power supplies

– Battery management systems

– Solar inverters

RAYMING’s aluminum PCBs can handle high currents and voltages while providing efficient heat dissipation. This helps improve the reliability and efficiency of power electronic systems.

3. Automotive Electronics

The automotive industry is increasingly using aluminum PCBs for various electronic systems such as:

– Engine control units (ECU)

– LED headlights and taillights

– Electric power steering

– Battery management systems for electric vehicles

– Advanced driver assistance systems (ADAS)

RAYMING’s aluminum PCBs meet the strict quality and reliability requirements of the automotive industry. They can withstand harsh environments, vibrations, and temperature extremes.

4. Aerospace and Defense

Aluminum PCBs are used in various aerospace and defense applications that require high reliability and performance such as:

– Avionics

– Radar systems

– Satellite communications

– Missile guidance systems

RAYMING’s aluminum PCBs are manufactured in a certified facility that meets the stringent standards of the aerospace and defense industry such as IPC Class 3 and MIL-PRF-31032.

FAQ

1. What is the minimum order quantity (MOQ) for RAYMING’s aluminum PCBs?

The minimum order quantity varies depending on the specific requirements of the project such as board size, complexity, and materials. Generally, the MOQ ranges from 50 to 100 pieces. For high-volume production, RAYMING offers more competitive pricing.

2. How long does it take to manufacture aluminum PCBs at RAYMING?

The lead time for aluminum PCBs depends on factors such as complexity, materials, and order quantity. Typical lead times range from 2 to 4 weeks. Rush services are available for urgent projects.

3. Can RAYMING provide assembly services for aluminum PCBs?

Yes, RAYMING offers turnkey assembly services for aluminum PCBs including SMT, THT, and mixed assembly. We have state-of-the-art assembly lines and experienced technicians to ensure high-quality assembly.

4. What file formats does RAYMING accept for aluminum PCB design?

RAYMING accepts industry-standard file formats such as Gerber RS-274X, ODB++, and IPC-2581. We also provide free DFM (Design for Manufacturing) review services to ensure your design is optimized for production.

5. How does RAYMING ensure the quality of its aluminum PCBs?

RAYMING has a comprehensive quality management system that includes:

– Incoming material inspection

– In-process quality control

– Automated optical inspection (AOI)

– Electrical testing

– Visual inspection

– Thermal cycling and environmental testing

– Statistical process control (SPC)

Our facilities are certified to ISO 9001, ISO 14001, and IATF 16949 standards. We also comply with IPC and MIL standards for various industries.

Conclusion

RAYMING is a leading manufacturer of high-quality aluminum PCBs for various industries and applications. With our state-of-the-art facilities, advanced equipment, and experienced team, we can provide custom aluminum PCB solutions that meet your specific requirements. Whether you need simple single-layer boards or complex multilayer designs, RAYMING has the expertise and capabilities to deliver reliable and cost-effective aluminum PCBs. Contact us today to learn more about how we can help with your next project.

No responses yet