What are Start-stop Circuits?

Start-stop circuits are electrical circuits that are used to control the operation of machines or systems. They provide a means to start and stop the machine or system using push buttons or switches. These circuits are commonly used in industrial settings, such as manufacturing plants, where machines need to be started and stopped frequently.

Key Components of Start-Stop Circuits

The main components of a start-stop circuit include:

- Push Buttons: These are the input devices used to initiate the start and stop commands. There are two types of push buttons:

- START button (Normally Open): When pressed, it closes the circuit and initiates the starting sequence.

-

STOP button (Normally Closed): When pressed, it opens the circuit and initiates the stopping sequence.

-

Contactors: Contactors are electrically controlled switches that are used to switch high current loads. They consist of a coil and a set of contacts. When the coil is energized, the contacts close, allowing current to flow through the load.

-

Overload Protection: Overload protection devices, such as thermal overload relays or electronic overload relays, are used to protect the motor from excessive current draw. These devices monitor the current flowing through the motor and trip the circuit if the current exceeds a preset value.

-

Fuses or Circuit Breakers: Fuses or circuit breakers are used to protect the circuit from short circuits and overloads. They interrupt the power supply to the circuit in case of a fault, preventing damage to the equipment.

-

Indicator Lights: Indicator lights are used to provide visual feedback about the status of the circuit. They indicate whether the machine is running or stopped.

How Start-Stop Circuits Work

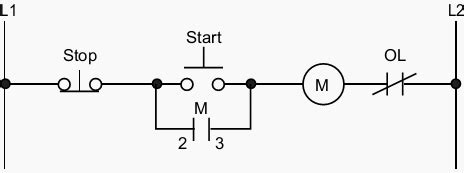

The working principle of a start-stop circuit is based on the interaction between the push buttons, contactors, and overload protection devices. Let’s take a closer look at the sequence of events in a typical start-stop circuit:

- Starting Sequence:

- When the START button is pressed, it closes the circuit and energizes the coil of the contactor.

- The contactor’s contacts close, allowing current to flow through the motor.

- The motor starts running.

-

The START button is released, but the contactor remains energized through a holding circuit (usually a normally open contact of the contactor itself).

-

Stopping Sequence:

- When the STOP button is pressed, it opens the circuit and de-energizes the coil of the contactor.

- The contactor’s contacts open, interrupting the current flow to the motor.

- The motor stops running.

-

The STOP button is released, and the circuit is ready for the next start command.

-

Overload Protection:

- If the motor draws excessive current, the overload protection device (thermal overload relay or electronic overload relay) trips.

- The overload protection device opens the circuit, de-energizing the contactor’s coil and stopping the motor.

- The overload protection device needs to be reset manually or automatically (depending on the type) before the motor can be started again.

Here’s a simple diagram illustrating the basic components and their connections in a start-stop circuit:

START STOP

(NO) (NC)

| |

| |

| |

| |

| |

+--------+ +--------+

| |

| |

+---+---+ +---+---+

| | | |

| Coil | | OLR |

| | | |

+---+---+ +---+---+

| |

| |

| |

+---+---+ +---+---+

| | | |

| M | | M |

| | | |

+-------+ +-------+

Controlling Start-Stop Circuits

Start-stop circuits can be controlled using various methods depending on the application and the level of automation required. Some common control methods include:

-

Manual Control: In manual control, the start and stop commands are initiated by an operator pressing the START and STOP buttons. This method is suitable for applications where manual intervention is necessary or desired.

-

Automatic Control: Automatic control involves the use of sensors, timers, or other control devices to initiate the start and stop commands based on predefined conditions. For example:

- A pressure switch can be used to start the motor when the pressure in a tank falls below a certain level and stop the motor when the pressure reaches a desired level.

-

A timer can be used to start and stop the motor at specific intervals for a predetermined duration.

-

PLC (Programmable Logic Controller) Control: PLCs are widely used in industrial automation to control start-stop circuits. The PLC receives inputs from sensors or other devices and executes a program to control the outputs, including the start and stop commands for the motor. PLCs offer flexibility, scalability, and advanced control features.

-

Relay Logic Control: Relay logic control uses a combination of relays and other control devices to implement the start-stop control logic. Relays are electrically operated switches that can be used to control the contactor’s coil based on the state of the input devices (push buttons, sensors, etc.).

Advantages of Start-Stop Circuits

Start-stop circuits offer several advantages in industrial applications:

-

Simplicity: Start-stop circuits provide a simple and intuitive way to control machines or systems. The use of push buttons makes it easy for operators to start and stop the machine as needed.

-

Safety: Start-stop circuits incorporate safety features such as overload protection and emergency stop functionality. These features protect the equipment and ensure the safety of personnel working around the machine.

-

Flexibility: Start-stop circuits can be adapted to various control methods, allowing for manual control, automatic control, or integration with PLCs or other control systems.

-

Cost-effective: Start-stop circuits are relatively inexpensive compared to more complex control systems. They provide a cost-effective solution for applications where basic start-stop control is sufficient.

FAQ

-

Q: What is the purpose of a start-stop circuit?

A: The purpose of a start-stop circuit is to control the operation of a machine or system by providing a means to start and stop it using push buttons or switches. -

Q: What are the main components of a start-stop circuit?

A: The main components of a start-stop circuit include push buttons (START and STOP), contactors, overload protection devices (thermal overload relays or electronic overload relays), fuses or circuit breakers, and indicator lights. -

Q: How does the overload protection device work in a start-stop circuit?

A: The overload protection device monitors the current flowing through the motor and trips the circuit if the current exceeds a preset value. This protects the motor from excessive current draw and prevents damage to the equipment. -

Q: Can start-stop circuits be controlled automatically?

A: Yes, start-stop circuits can be controlled automatically using sensors, timers, or other control devices. These devices initiate the start and stop commands based on predefined conditions or time intervals. -

Q: What are the advantages of using start-stop circuits in industrial applications?

A: Start-stop circuits offer advantages such as simplicity, safety, flexibility, and cost-effectiveness. They provide a simple and intuitive way to control machines, incorporate safety features, and can be adapted to various control methods.

Conclusion

Start-stop circuits are fundamental components in the field of electrical engineering and automation. They provide a simple and effective way to control the operation of machines and systems by allowing operators to start and stop them using push buttons. Understanding the components, working principles, and control methods of start-stop circuits is crucial for designing and implementing efficient and safe control systems in industrial applications.

By incorporating overload protection, safety features, and flexibility in control methods, start-stop circuits offer a reliable and cost-effective solution for a wide range of applications. As technology advances, start-stop circuits continue to evolve, integrating with more advanced control systems such as PLCs and relay logic control to meet the growing demands of modern industrial automation.

No responses yet