Introduction to Altium Designer and RAYPCB

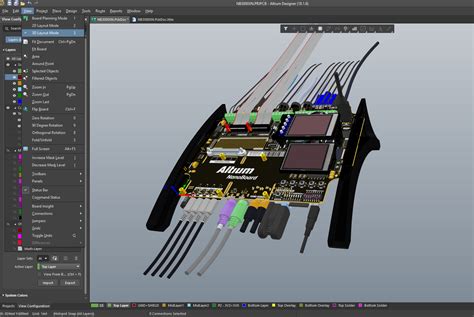

Altium Designer is a powerful electronic design automation (EDA) software that enables engineers to design printed Circuit Boards (PCBs) efficiently. It offers a comprehensive set of tools for schematic capture, PCB Layout, and design verification. One of the key features of Altium Designer is its ability to create and use design templates, which can significantly speed up the design process and ensure consistency across projects.

RAYPCB is a leading PCB manufacturing company that provides high-quality PCB Fabrication and assembly services. They have established a set of design rules and guidelines to ensure the manufacturability and reliability of PCBs. By incorporating these design rules into Altium Designer templates, engineers can create designs that are optimized for RAYPCB’s manufacturing processes.

Benefits of Using Altium Designer Templates with RAYPCB Design Rules

- Improved Design Efficiency

- Enhanced Design Consistency

- Reduced Design Errors

- Faster Time-to-Market

- Cost Savings

Creating Altium Designer Templates with RAYPCB Design Rules

Step 1: Setting Up the PCB Project

To create an Altium Designer template with RAYPCB design rules, start by creating a new PCB project. Follow these steps:

- Open Altium Designer and click on “File” > “New” > “Project”.

- Select “PCB Project” and choose a location to save the project.

- Give the project a meaningful name, such as “RAYPCB_Template”.

Step 2: Configuring the PCB Document

Next, configure the PCB document settings to match RAYPCB’s design rules. Here’s how:

- Double-click on the PCB document in the Projects panel to open it.

- Go to “Design” > “Board Options” to access the PCB document settings.

- In the “Board Options” dialog box, navigate to the “Design Rules” tab.

- Click on the “Import” button and select the RAYPCB design rules file (usually provided by RAYPCB).

- Review the imported design rules and make any necessary adjustments.

Step 3: Defining Layer Stack and Materials

Define the layer stack and materials according to RAYPCB’s specifications. Follow these steps:

- In the PCB document, go to “Design” > “Layer Stack Manager”.

- In the “Layer Stack Manager” dialog box, define the number of layers and their properties (e.g., thickness, material, color).

- Ensure that the layer stack matches RAYPCB’s requirements for the specific PCB type (e.g., standard, high-speed, or high-density interconnect).

Step 4: Creating Reusable Components and Footprints

Identify commonly used components in your designs and create reusable components and footprints that adhere to RAYPCB’s design guidelines. Here’s how:

- In Altium Designer, open the “Components” panel and click on the “Libraries” tab.

- Create a new library or open an existing one to store the reusable components.

- For each component, create a schematic symbol and a PCB footprint that meet RAYPCB’s requirements (e.g., pad size, spacing, and drill sizes).

- Assign appropriate 3D models and parameters to the components for accurate visualization and design rule checking.

Step 5: Setting Up Design Rule Checks (DRC)

Configure the Design Rule Check (DRC) settings to ensure that your designs comply with RAYPCB’s manufacturing constraints. Follow these steps:

- In the PCB document, go to “Tools” > “Design Rule Check”.

- In the “Design Rule Check” dialog box, select the appropriate rule set based on RAYPCB’s design rules.

- Customize the DRC settings, if necessary, to match your specific design requirements.

- Run the DRC and address any violations before proceeding with the design.

Step 6: Creating the PCB Layout Template

Create a PCB layout template that incorporates RAYPCB’s recommended layout practices and design rules. Here’s how:

- In the PCB document, set up the board outline and dimensions according to your design requirements.

- Define the placement of key components, such as connectors, power supplies, and mounting holes, following RAYPCB’s guidelines.

- Create a component placement grid that aligns with RAYPCB’s manufacturing capabilities.

- Set up appropriate routing rules, such as Track width, spacing, and via sizes, based on RAYPCB’s design rules.

- Define copper pour and plane areas, ensuring proper clearances and thermal relief settings.

Step 7: Documenting and Saving the Template

Document the template’s features and guidelines to help other engineers understand and utilize it effectively. Follow these steps:

- Create a README file that outlines the purpose, features, and usage instructions for the template.

- Include information about RAYPCB’s design rules and any specific requirements that the template adheres to.

- Save the template project in a centralized location, such as a shared network drive or a version control system, for easy access and collaboration.

Using Altium Designer Templates with RAYPCB Design Rules

Step 1: Starting a New Project

To start a new project using the RAYPCB template, follow these steps:

- Open Altium Designer and click on “File” > “New” > “Project”.

- Select “PCB Project” and choose the location where you want to save the project.

- In the “New Project” dialog box, click on the “Use Template” button.

- Browse to the location where you saved the RAYPCB template and select it.

- Give the project a meaningful name and click “OK” to create the new project based on the template.

Step 2: Customizing the Template

Customize the template to fit your specific design requirements. Here are some aspects you may need to modify:

- Update the schematic and PCB layout to include your specific components and circuitry.

- Adjust the layer stack and materials if your design requires a different configuration than the template.

- Modify the component placement and routing as needed while adhering to RAYPCB’s design rules.

- Update the design parameters, such as track width and spacing, to match your design’s specific requirements.

Step 3: Running Design Rule Checks

Regularly run Design Rule Checks (DRC) to ensure that your design complies with RAYPCB’s manufacturing constraints. Follow these steps:

- In the PCB document, go to “Tools” > “Design Rule Check”.

- Ensure that the appropriate rule set, based on RAYPCB’s design rules, is selected.

- Run the DRC and carefully review any violations or warnings.

- Make necessary changes to your design to resolve any issues flagged by the DRC.

Step 4: Generating Manufacturing Files

Once your design is complete and has passed the DRC, generate the necessary manufacturing files for RAYPCB. Follow these steps:

- In the PCB document, go to “File” > “Fabrication Outputs”.

- Select the appropriate output format, such as Gerber or ODB++, based on RAYPCB’s requirements.

- Configure the output settings, including layer mapping and file naming conventions, according to RAYPCB’s specifications.

- Generate the manufacturing files and review them for accuracy and completeness.

Step 5: Communicating with RAYPCB

Maintain clear communication with RAYPCB throughout the design and manufacturing process. Here are some tips:

- Provide RAYPCB with the complete set of manufacturing files, including the Gerber or ODB++ files, drill files, and any additional documentation.

- Clearly communicate any special requirements or design intent to RAYPCB’s technical support team.

- Respond promptly to any questions or clarifications requested by RAYPCB to avoid delays in the manufacturing process.

- Work closely with RAYPCB to resolve any issues that may arise during the fabrication and assembly stages.

Best Practices for Using Altium Designer Templates with RAYPCB Design Rules

- Keep Templates Up-to-Date

- Collaborate with RAYPCB

- Validate Design Rules Regularly

- Use Consistent Naming Conventions

- Document Template Changes

Common Mistakes to Avoid

- Neglecting to Update Templates

- Overriding Design Rules

- Inconsistent Layer Stack Definition

- Incomplete or Inaccurate Manufacturing Files

- Poor Communication with RAYPCB

Frequently Asked Questions (FAQ)

1. How often should I update my Altium Designer templates with RAYPCB’s design rules?

It is recommended to update your templates whenever RAYPCB releases new design rules or guidelines. Additionally, review your templates periodically (e.g., every 6 months) to ensure they are up-to-date with the latest industry standards and best practices.

2. Can I modify the design rules in the template to suit my specific requirements?

Yes, you can modify the design rules in the template to accommodate your specific design requirements. However, it is essential to communicate any deviations from RAYPCB’s standard design rules to their technical support team to ensure manufacturability and avoid potential issues.

3. What should I do if I encounter a design rule violation that I cannot resolve?

If you encounter a design rule violation that you cannot resolve, consult with RAYPCB’s technical support team. They can provide guidance on how to address the issue while maintaining manufacturability. In some cases, they may suggest alternative design approaches or offer specific recommendations based on their expertise.

4. How can I ensure that my design is compatible with RAYPCB’s manufacturing capabilities?

To ensure compatibility with RAYPCB’s manufacturing capabilities, follow these steps:

- Use the Altium Designer template that incorporates RAYPCB’s design rules and guidelines.

- Regularly run Design Rule Checks (DRC) to identify and resolve any violations.

- Communicate with RAYPCB’s technical support team regarding any specific requirements or concerns.

- Provide accurate and complete manufacturing files to RAYPCB, following their specifications.

5. What are the benefits of using Altium Designer templates with RAYPCB’s design rules?

Using Altium Designer templates with RAYPCB’s design rules offers several benefits:

- Improved design efficiency by starting with a pre-configured template that adheres to RAYPCB’s manufacturing constraints.

- Enhanced design consistency across projects, ensuring that all designs meet RAYPCB’s standards.

- Reduced design errors and iterations, as the template helps prevent common mistakes and violations.

- Faster time-to-market by streamlining the design process and minimizing the need for revisions.

- Cost savings by avoiding unnecessary manufacturing delays or issues related to design non-compliance.

Conclusion

Altium Designer templates with RAYPCB design rules provide a powerful toolset for creating high-quality, manufacturable PCB designs. By incorporating RAYPCB’s design guidelines and constraints into your Altium Designer workflow, you can streamline the design process, reduce errors, and ensure compatibility with RAYPCB’s manufacturing capabilities.

Remember to keep your templates up-to-date, communicate effectively with RAYPCB, and regularly validate your designs against the established design rules. By following best practices and avoiding common mistakes, you can leverage the full potential of Altium Designer templates with RAYPCB design rules to create successful PCB projects.

No responses yet