1. Define Your Requirements

Before you start designing your PCB Prototype, clearly define your requirements. Consider factors such as:

- Size constraints

- Power requirements

- Component placement

- Connectivity

- Environmental conditions

By having a clear understanding of your requirements upfront, you can design a prototype that meets your specific needs.

2. Choose the Right Software

Selecting the right PCB design software is crucial for creating a high-quality prototype. Some popular options include:

- Altium Designer

- Eagle

- KiCad

- OrCAD

Consider factors such as ease of use, feature set, and compatibility with your existing tools when choosing your software.

3. Start with a Schematic

Begin your PCB prototype design by creating a schematic. A schematic is a graphical representation of your circuit, showing how components are connected. It serves as a blueprint for your PCB layout.

Tips for creating a schematic:

- Use clear and consistent naming conventions for components and nets

- Group related components together

- Use hierarchical design for complex circuits

4. Create a Component Library

A component library is a collection of footprints and symbols for the components you’ll use in your PCB design. Having a well-organized library can save you time and ensure consistency across your designs.

Tips for creating a component library:

- Use standard footprints when possible

- Create custom footprints for unique components

- Include relevant information such as manufacturer part numbers and datasheets

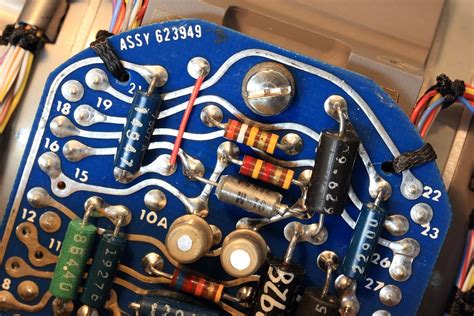

5. Design Your PCB Layout

With your schematic and component library in place, you can start designing your PCB layout. The layout determines the physical placement of components and routing of traces on your board.

Tips for designing your PCB layout:

- Follow good design practices such as minimizing trace lengths and avoiding sharp angles

- Use ground planes to reduce noise and improve signal integrity

- Consider manufacturability, such as minimum trace widths and clearances

6. Perform Design Rule Checks (DRC)

Design Rule Checks (DRC) help identify potential issues in your PCB layout, such as short circuits, insufficient clearances, or missing connections. Running DRC throughout your design process can catch problems early and save time in the long run.

Tips for running DRC:

- Set up your DRC rules based on your manufacturer’s specifications

- Run DRC regularly, especially after making significant changes to your layout

- Review and address all DRC violations before moving to prototype fabrication

7. Generate Gerber Files

Gerber files are the industry standard format for PCB fabrication. They contain all the necessary information for manufacturing your PCB, including copper layers, solder mask, and silkscreen.

Tips for generating Gerber files:

- Use a standard naming convention for your Gerber files

- Include all necessary layers, such as drill files and assembly drawings

- Verify your Gerber files using a viewer to ensure accuracy

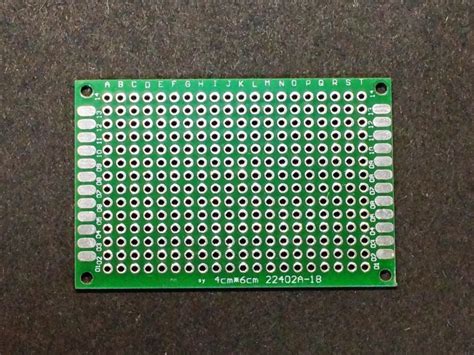

8. Choose the Right Prototype Fabrication Method

There are several methods for fabricating PCB prototypes, each with its own advantages and disadvantages. Common methods include:

| Method | Advantages | Disadvantages |

|---|---|---|

| Quick-turn PCB services | Fast turnaround time, low cost for small quantities | Limited customization options, higher cost for larger quantities |

| In-house fabrication | Full control over the process, faster iterations | Requires investment in equipment and expertise |

| 3D printing | Rapid prototyping, complex geometries possible | Limited material options, lower resolution compared to traditional methods |

Choose the fabrication method that best suits your needs based on factors such as time, cost, and required features.

9. Assemble and Test Your Prototype

Once you have your PCB prototype fabricated, it’s time to assemble the components and test your design. This step allows you to validate your design and identify any issues before moving to full production.

Tips for assembling and testing your prototype:

- Use proper ESD protection when handling components

- Follow the assembly instructions carefully, referring to your schematic and layout

- Perform functional tests to verify your prototype meets your requirements

- Document any issues or areas for improvement

10. Iterate and Refine Your Design

Based on the results of your prototype testing, you may need to iterate and refine your design. This process involves making changes to your schematic, layout, or component selection to address any issues or improve performance.

Tips for iterating and refining your design:

- Prioritize changes based on their impact and feasibility

- Keep detailed notes of your changes and their rationale

- Communicate changes with your team and stakeholders

- Repeat the prototyping process as necessary until you achieve your desired results

Frequently Asked Questions (FAQ)

1. How long does it take to create a PCB prototype?

The time required to create a PCB prototype depends on several factors, such as the complexity of your design, the fabrication method chosen, and the workload of your manufacturer. Quick-turn PCB services can often provide prototypes within a few days, while more complex designs or in-house fabrication may take several weeks.

2. How much does it cost to create a PCB prototype?

The cost of creating a PCB prototype varies based on factors such as the size of your board, the number of layers, the quantity ordered, and the fabrication method. Quick-turn PCB services typically charge a premium for their fast turnaround times, while in-house fabrication may have higher upfront costs but lower per-unit costs for larger quantities.

3. What are some common mistakes to avoid when creating a PCB prototype?

Some common mistakes to avoid when creating a PCB prototype include:

- Failing to define clear requirements upfront

- Not following good design practices, such as proper grounding and signal routing

- Skipping Design Rule Checks (DRC) or not addressing violations

- Not verifying Gerber files before sending them to fabrication

- Rushing the assembly and testing process

4. How do I choose the right components for my PCB prototype?

When choosing components for your PCB prototype, consider factors such as:

- Functionality and performance requirements

- Availability and lead times

- Cost and budget constraints

- Footprint and package compatibility with your PCB layout

- Compliance with relevant standards and regulations

Research and compare components from multiple manufacturers, and consider consulting with experienced engineers or your PCB manufacturer for guidance.

5. Can I use a PCB prototype for full production?

While a PCB prototype can be used for small-scale production runs, it is generally not recommended for full production. Prototypes are designed to validate your design and identify areas for improvement, and may not be optimized for large-scale manufacturing. Once you have finalized your design based on prototype testing, work with your PCB manufacturer to develop a production-ready version of your board.

Conclusion

Creating a PCB prototype is a critical step in the product development process, allowing you to test and refine your design before committing to full production. By following these 10 ways to make a prototype for your exact needs, you can ensure a successful outcome for your project.

Remember to:

- Define your requirements clearly

- Choose the right software and tools

- Start with a well-organized schematic

- Create a comprehensive component library

- Follow good design practices in your PCB layout

- Perform regular Design Rule Checks (DRC)

- Generate accurate Gerber files

- Select the appropriate prototype fabrication method

- Assemble and test your prototype thoroughly

- Iterate and refine your design based on prototype results

By working closely with your PCB manufacturer and leveraging their expertise, you can streamline the prototyping process and bring your product to market faster and with greater success.

No responses yet