Introduction to Xenon Flash Circuits

A xenon flash circuit is an electronic circuit that generates a brief, intense burst of light using a xenon flash tube. These circuits are commonly used in photography, strobe lights, and other applications requiring a powerful, short-duration light source. In this article, we will explore the components, working principles, and step-by-step instructions for building a xenon flash circuit.

Components Required for a Xenon Flash Circuit

To build a xenon flash circuit, you will need the following components:

| Component | Description |

|---|---|

| Xenon Flash Tube | The main light-emitting element in the circuit. |

| High Voltage Power Supply | Provides the necessary high voltage to trigger and maintain the xenon flash tube. |

| Capacitor | Stores the energy required for the flash. |

| Trigger Transformer | Steps up the trigger voltage to initiate the flash. |

| Trigger Circuit | Controls the timing and duration of the flash. |

| Resistors and Diodes | Used for current limiting and protection in the circuit. |

Xenon Flash Tube

The xenon flash tube is a gas-filled tube that contains two electrodes and a small amount of xenon gas. When a high voltage is applied across the electrodes, the xenon gas ionizes and conducts electricity, resulting in a bright flash of light. Xenon flash tubes are available in various sizes and shapes, depending on the application and required light output.

High Voltage Power Supply

To operate a xenon flash tube, a high voltage power supply is necessary. The power supply should be capable of providing a voltage between 200V and 1000V, depending on the specific xenon tube being used. A common choice for xenon flash circuits is a flyback transformer-based power supply, which can step up a low voltage DC input to the required high voltage.

Capacitor

The capacitor in a xenon flash circuit stores the energy required for the flash. The capacitor is charged by the high voltage power supply and discharged through the xenon tube when the flash is triggered. The capacitance value depends on the desired flash duration and intensity. Typical values range from a few microfarads to several hundred microfarads.

Trigger Transformer

The trigger transformer steps up the trigger voltage from the trigger circuit to a level sufficient to ionize the xenon gas and initiate the flash. The primary winding of the trigger transformer is connected to the trigger circuit, while the secondary winding is connected to the xenon tube’s trigger electrode.

Trigger Circuit

The trigger circuit controls the timing and duration of the flash. It typically consists of a low-voltage pulse generator, such as a 555 timer IC or a microcontroller, which sends a pulse to the primary winding of the trigger transformer. The trigger circuit can be designed to generate single flashes or repetitive flashes at a desired frequency.

Resistors and Diodes

Resistors and diodes are used in the xenon flash circuit for current limiting and protection. A current-limiting resistor is placed in series with the xenon tube to prevent excessive current flow, which could damage the tube or other components. Diodes are used to protect the circuit from reverse voltage spikes that may occur during the flash discharge.

Working Principle of a Xenon Flash Circuit

The working principle of a xenon flash circuit can be summarized as follows:

- The high voltage power supply charges the capacitor to the desired voltage.

- The trigger circuit generates a low-voltage pulse, which is applied to the primary winding of the trigger transformer.

- The trigger transformer steps up the voltage and applies it to the trigger electrode of the xenon flash tube.

- The high voltage across the xenon tube’s electrodes ionizes the xenon gas, causing it to conduct electricity.

- The capacitor discharges through the xenon tube, resulting in a bright flash of light.

- The capacitor recharges, and the cycle repeats as desired.

Step-by-Step Guide to Building a Xenon Flash Circuit

Step 1: Choosing the Components

Select the appropriate components for your xenon flash circuit based on the desired light output, flash duration, and power requirements. Ensure that the xenon flash tube, high voltage power supply, capacitor, and trigger transformer are compatible and rated for the intended application.

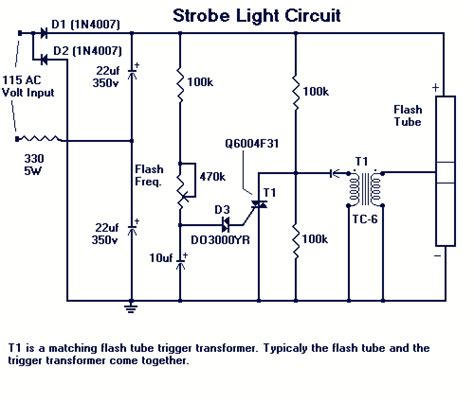

Step 2: Designing the Circuit

Create a schematic diagram of the xenon flash circuit, including all the necessary components and their connections. Use the schematic as a reference during the assembly process.

Step 3: Assembling the Power Supply

Build the high voltage power supply according to the chosen design. If using a flyback transformer, follow the appropriate winding and feedback circuit guidelines. Test the power supply to ensure it provides the required voltage for the xenon flash tube.

Step 4: Constructing the Trigger Circuit

Assemble the trigger circuit using the selected components, such as a 555 timer IC or a microcontroller. Design the circuit to generate the desired trigger pulses for the xenon flash tube. Test the trigger circuit to verify its functionality.

Step 5: Connecting the Components

Connect the components according to the schematic diagram. Pay attention to the polarity of the capacitor and the connections of the xenon flash tube. Use appropriate wire gauges and insulation to handle the high voltages involved.

Step 6: Testing and Troubleshooting

Once the circuit is assembled, test it with caution. Ensure proper safety precautions are taken, as the circuit deals with high voltages. If the flash does not work as expected, troubleshoot the circuit by checking connections, component values, and power supply output. Use a multimeter or oscilloscope to diagnose any issues.

Step 7: Finalizing the Circuit

After the circuit is functioning correctly, consider adding any additional features or protections, such as a trigger switch, a flash intensity control, or a protective enclosure. Ensure that the circuit is properly insulated and secured to prevent accidental contact with high voltage components.

Safety Considerations

When working with xenon flash circuits, it is essential to prioritize safety due to the high voltages involved. Always follow these safety guidelines:

- Work in a well-ventilated area and wear protective eyewear to avoid exposure to the bright flash.

- Use insulated tools and wear rubber gloves when handling high voltage components.

- Discharge the capacitor before making any circuit adjustments or repairs.

- Keep the circuit away from flammable materials and moisture.

- Never touch the xenon flash tube or any exposed high voltage points when the circuit is powered on.

Applications of Xenon Flash Circuits

Xenon flash circuits find applications in various fields, including:

-

Photography: Used in camera flashes and studio strobe lights for capturing images in low-light conditions or freezing fast-moving subjects.

-

Warning lights: Employed in emergency vehicles, aircraft, and industrial equipment to provide high-intensity, attention-grabbing light signals.

-

Scientific instrumentation: Utilized in spectroscopy, microscopy, and other analytical techniques requiring short, intense light pulses.

-

Entertainment: Incorporated into stage lighting and special effects for concerts, theaters, and other events.

-

Optogenetics: Used to stimulate light-sensitive proteins in biological research and neuroscience experiments.

Frequently Asked Questions (FAQ)

1. What is the typical voltage required for a xenon flash tube?

The voltage required for a xenon flash tube depends on its size and specifications. Typically, xenon flash tubes operate between 200V and 1000V. Smaller tubes may require lower voltages, while larger tubes may need higher voltages for optimal performance.

2. How long does a xenon flash last?

The duration of a xenon flash depends on the capacitance value and the discharge circuit design. Typical flash durations range from a few microseconds to several milliseconds. The flash duration can be controlled by adjusting the capacitor size and the discharge circuit parameters.

3. Can I use a regular power supply for a xenon flash circuit?

No, a regular power supply is not suitable for a xenon flash circuit. Xenon flash tubes require high voltages to ionize the xenon gas and produce the flash. A dedicated high voltage power supply, such as a flyback transformer-based design, is necessary to provide the required voltage.

4. How often can a xenon flash circuit be triggered?

The maximum trigger frequency of a xenon flash circuit depends on the capacitor’s recharge time and the flash tube’s recovery time. The recharge time is determined by the capacitor size and the power supply’s current capability. The flash tube’s recovery time depends on its specifications and the cooling system employed. Typical maximum trigger frequencies range from a few hertz to several hundred hertz.

5. What safety precautions should I take when working with xenon flash circuits?

When working with xenon flash circuits, always prioritize safety. Work in a well-ventilated area, wear protective eyewear, and use insulated tools. Discharge the capacitor before making any circuit adjustments, and never touch the xenon flash tube or exposed high voltage points when the circuit is powered on. Keep the circuit away from flammable materials and moisture.

Conclusion

Building a xenon flash circuit requires an understanding of the components, working principles, and safety considerations involved. By following the step-by-step guide and taking the necessary precautions, you can construct a functional xenon flash circuit for various applications, such as photography, warning lights, scientific instrumentation, and entertainment. Remember to prioritize safety when working with high voltages and always adhere to the proper guidelines to ensure a successful and safe project.

No responses yet