Introduction to Silver-Gold PCB

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are used in almost every electronic device, from smartphones and laptops to industrial control systems and medical equipment. PCBs are essentially a substrate made of insulating material, such as fiberglass or plastic, with conductive traces etched onto the surface to connect electronic components.

One of the most critical aspects of PCB design is the choice of materials used for the conductive traces. While copper is the most common material used for PCB traces, silver and gold are also used in certain applications. In this article, we will explore the reasons why silver and gold are used in electronic circuits to build a basic PCB board.

Properties of Silver and Gold

Silver Properties

Silver is a highly conductive metal, with an electrical conductivity of 6.30 x 10^7 S/m, which is the highest among all metals. It is also highly reflective, with a reflectivity of 95% in the visible spectrum. Silver has a relatively low melting point of 961.8°C, which makes it easy to work with during PCB fabrication.

| Property | Value |

|---|---|

| Electrical Conductivity | 6.30 x 10^7 S/m |

| Reflectivity | 95% |

| Melting Point | 961.8°C |

Gold Properties

Gold is another highly conductive metal, with an electrical conductivity of 4.10 x 10^7 S/m, which is second only to silver. Gold is also highly resistant to corrosion and oxidation, which makes it an ideal choice for PCB traces in harsh environments. Gold has a relatively high melting point of 1064.18°C, which makes it more difficult to work with during PCB fabrication compared to silver.

| Property | Value |

|---|---|

| Electrical Conductivity | 4.10 x 10^7 S/m |

| Corrosion Resistance | High |

| Melting Point | 1064.18°C |

Advantages of Using Silver and Gold in PCBs

High Conductivity

One of the main advantages of using silver and gold in PCBs is their high electrical conductivity. This means that PCBs made with silver or gold traces can transmit signals more efficiently than those made with copper traces. This is particularly important in high-frequency applications, where signal integrity is critical.

Corrosion Resistance

Another advantage of using gold in PCBs is its high resistance to corrosion and oxidation. This makes gold an ideal choice for PCBs that will be exposed to harsh environments, such as those found in industrial or marine applications. Silver, while not as resistant to corrosion as gold, is still more resistant than copper.

Improved Signal Integrity

Using silver or gold in PCBs can also improve signal integrity, particularly in high-frequency applications. This is because silver and gold have lower resistivity than copper, which means that signals can travel through the traces with less attenuation and distortion.

Disadvantages of Using Silver and Gold in PCBs

High Cost

The main disadvantage of using silver and gold in PCBs is their high cost compared to copper. Silver and gold are precious metals, and their prices can fluctuate significantly based on market conditions. This means that PCBs made with silver or gold traces can be significantly more expensive than those made with copper traces.

Difficult to Work With

Another disadvantage of using silver and gold in PCBs is that they can be more difficult to work with during PCB fabrication. Silver and gold have higher melting points than copper, which means that they require higher temperatures and more precise control during soldering and other fabrication processes.

Applications of Silver-Gold PCBs

High-Frequency Applications

Silver-gold PCBs are commonly used in high-frequency applications, such as RF and microwave circuits. This is because silver and gold have lower resistivity than copper, which means that signals can travel through the traces with less attenuation and distortion. This is particularly important in applications where signal integrity is critical, such as in wireless communication systems.

Harsh Environments

Gold-plated PCBs are also commonly used in applications where the PCB will be exposed to harsh environments, such as in industrial or marine applications. Gold’s high resistance to corrosion and oxidation makes it an ideal choice for these applications, where the PCB may be exposed to moisture, chemicals, or extreme temperatures.

Medical Devices

Silver-gold PCBs are also used in medical devices, particularly in implantable devices such as pacemakers and defibrillators. This is because silver and gold are biocompatible materials that do not cause adverse reactions when in contact with human tissue. Additionally, the high conductivity and signal integrity of silver-gold PCBs make them ideal for use in these critical applications.

Fabrication of Silver-Gold PCBs

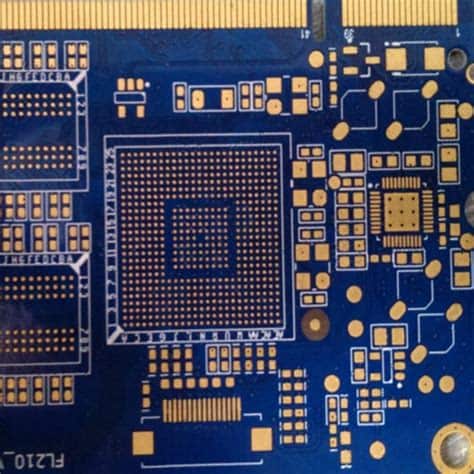

Plating Process

The most common method of fabricating silver-gold PCBs is through a plating process. In this process, a thin layer of silver or gold is deposited onto the surface of the copper traces using an electroplating process. The thickness of the plating layer can vary depending on the application, but is typically in the range of 0.5 to 2 microns.

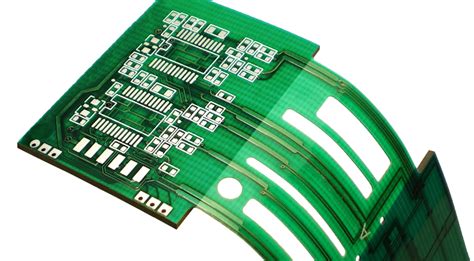

Sputtering Process

Another method of fabricating silver-gold PCBs is through a sputtering process. In this process, a thin layer of silver or gold is deposited onto the surface of the PCB using a physical vapor deposition process. This process can produce very thin and uniform layers of silver or gold, but is typically more expensive than the plating process.

Conclusion

In conclusion, silver and gold are used in electronic circuits to build basic PCB boards for a variety of reasons. Their high conductivity, corrosion resistance, and improved signal integrity make them ideal for use in high-frequency applications, harsh environments, and medical devices. While silver-gold PCBs are more expensive than copper PCBs, their benefits often outweigh the costs in these critical applications.

Frequently Asked Questions (FAQ)

-

Q: What are the main advantages of using silver and gold in PCBs?

A: The main advantages of using silver and gold in PCBs are their high conductivity, corrosion resistance, and improved signal integrity. -

Q: What are the main disadvantages of using silver and gold in PCBs?

A: The main disadvantages of using silver and gold in PCBs are their high cost compared to copper and the fact that they can be more difficult to work with during PCB fabrication. -

Q: What are some common applications of silver-gold PCBs?

A: Some common applications of silver-gold PCBs include high-frequency applications such as RF and microwave circuits, harsh environments such as industrial or marine applications, and medical devices such as pacemakers and defibrillators. -

Q: What is the most common method of fabricating silver-gold PCBs?

A: The most common method of fabricating silver-gold PCBs is through a plating process, where a thin layer of silver or gold is deposited onto the surface of the copper traces using an electroplating process. -

Q: Are silver-gold PCBs more expensive than copper PCBs?

A: Yes, silver-gold PCBs are typically more expensive than copper PCBs due to the higher cost of the precious metals used in their fabrication.

No responses yet