Introduction to Vapor Phase Reflow

Vapor phase reflow is a soldering technique used in the assembly of printed circuit boards (PCBs) that offers several advantages over traditional convection reflow methods. In this process, the PCB assembly is subjected to a hot vapor blanket generated by the boiling of a heat transfer liquid, which provides a uniform and efficient heat transfer to the components and solder joints. This technology has gained popularity in recent years due to its ability to address the challenges posed by the increasing complexity and density of modern electronic assemblies.

How Vapor Phase Reflow Works

The vapor phase reflow process involves the following steps:

- The PCB assembly is preheated to activate the flux and remove any moisture.

- The assembly is then lowered into a vapor blanket generated by a boiling heat transfer liquid, typically a perfluoropolyether (PFPE) fluid.

- The vapor condenses on the cooler surfaces of the PCB and components, transferring its latent heat of vaporization uniformly across the assembly.

- As the PCB reaches the vapor temperature, the solder paste melts and forms reliable solder joints between the components and the board.

- The assembly is then lifted out of the vapor blanket and allowed to cool, solidifying the solder joints.

Advantages of Vapor Phase Reflow

Vapor phase reflow offers several key advantages over traditional convection reflow methods:

- Uniform heat transfer: The condensation of the vapor on the PCB surface ensures a uniform and efficient heat transfer, minimizing temperature gradients and reducing the risk of thermal stress on components.

- Improved soldering quality: The even heat distribution leads to more consistent and reliable solder joint formation, reducing the occurrence of defects such as bridging, tombstoning, and voiding.

- Reduced energy consumption: Vapor phase reflow requires less energy compared to convection reflow, as the latent heat of vaporization is efficiently transferred to the PCB assembly.

- Flexibility in board design: The uniform heating allows for greater flexibility in component placement and board layout, as the process is less sensitive to variations in thermal mass and component shadowing.

The Need for Vapor Phase Reflow Technology

Increasing Complexity of Electronic Assemblies

Modern electronic devices are becoming increasingly complex, with higher component densities, smaller form factors, and more diverse component packages. This complexity poses several challenges for the soldering process, including:

- Maintaining consistent solder joint quality across the entire assembly

- Avoiding thermal damage to sensitive components

- Ensuring proper soldering of fine-pitch and ball grid array (BGA) components

- Minimizing warpage and thermal stress on the PCB

Vapor phase reflow technology addresses these challenges by providing a uniform and controlled heating environment that ensures consistent solder joint formation and reduces the risk of thermal damage to components.

Limitations of Conventional Reflow Methods

Conventional convection reflow methods, such as forced air convection and infrared (IR) reflow, have several limitations when dealing with complex electronic assemblies:

- Temperature gradients: Convection reflow can result in temperature gradients across the PCB, leading to uneven heating and potential thermal stress on components.

- Shadow effect: Taller components can shield smaller components from the hot air flow, causing insufficient heating and poor solder joint formation.

- Difficulty in soldering fine-pitch components: The uneven heating in convection reflow can cause issues such as bridging and tombstoning when soldering fine-pitch components.

- Energy inefficiency: Convection reflow requires a significant amount of energy to maintain the hot air flow and compensate for heat losses.

Vapor phase reflow overcomes these limitations by providing a uniform and efficient heating environment that ensures consistent solder joint quality, regardless of component size, placement, or thermal mass.

Meeting Industry Standards and Regulations

The electronics industry is subject to various standards and regulations that govern the quality, reliability, and environmental impact of electronic products. Vapor phase reflow technology helps manufacturers meet these requirements by:

- Ensuring consistent solder joint quality: The uniform heating provided by vapor phase reflow results in more reliable and consistent solder joints, helping manufacturers meet quality standards such as IPC-A-610.

- Reducing the use of hazardous substances: Vapor phase reflow can be used with lead-free solder pastes, helping manufacturers comply with regulations such as the Restriction of Hazardous Substances (RoHS) directive.

- Improving energy efficiency: The lower energy consumption of vapor phase reflow compared to convection reflow helps manufacturers meet energy efficiency standards and reduce their environmental impact.

Applications of Vapor Phase Reflow

Vapor phase reflow technology has found applications in various industries and product categories, including:

- Consumer electronics: Smartphones, tablets, laptops, and wearables

- Automotive electronics: Engine control units, infotainment systems, and advanced driver assistance systems (ADAS)

- Medical devices: Implantable devices, diagnostic equipment, and patient monitoring systems

- Aerospace and defense: Avionics, satellite components, and military communication systems

- Industrial electronics: Process control systems, automation equipment, and power electronics

In each of these applications, vapor phase reflow has proven to be an effective solution for ensuring reliable and consistent solder joint quality, while reducing the risk of thermal damage to sensitive components.

Implementing Vapor Phase Reflow Technology

Equipment and Setup

To implement vapor phase reflow technology, manufacturers need to invest in specialized equipment and set up their production lines accordingly. The key components of a vapor phase reflow system include:

- Vapor phase reflow oven: The oven consists of a tank filled with a heat transfer liquid, heating elements to boil the liquid, and a condensation coil to control the vapor blanket height.

- Conveyor system: A conveyor system is used to transport the PCB assemblies into and out of the vapor blanket.

- Cooling station: After exiting the vapor blanket, the PCB assemblies need to be cooled to solidify the solder joints. This can be done using a cooling conveyor or a separate cooling station.

- Fume extraction: Vapor phase reflow ovens generate a small amount of fumes from the heat transfer liquid, which need to be extracted and filtered to maintain a safe working environment.

Process Optimization and Control

To ensure consistent and reliable results, the vapor phase reflow process needs to be optimized and controlled for each specific PCB assembly. Key process parameters include:

- Preheat temperature and time: The preheat stage is crucial for activating the flux and removing moisture from the PCB assembly. The preheat temperature and time should be optimized based on the specific solder paste and components used.

- Vapor temperature: The vapor temperature determines the maximum temperature the PCB assembly will reach during the reflow process. It should be set based on the solder paste specifications and the thermal limits of the components.

- Dwell time: The dwell time is the duration the PCB assembly spends in the vapor blanket. It should be long enough to ensure complete melting and wetting of the solder joints, but not so long as to cause thermal damage to the components.

- Cooling rate: The cooling rate affects the formation and reliability of the solder joints. A controlled cooling rate is necessary to avoid thermal shock and ensure proper solidification of the solder.

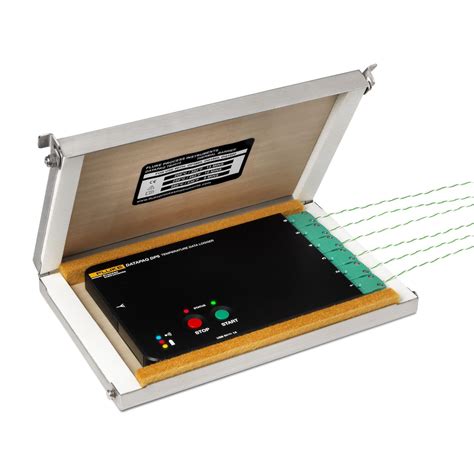

To optimize and control these parameters, manufacturers can use process monitoring and data logging systems that provide real-time feedback on the temperature profile and other key variables. This data can be used to fine-tune the process and ensure consistent results across different PCB assemblies and production runs.

Frequently Asked Questions (FAQ)

-

What is vapor phase reflow, and how does it differ from conventional reflow methods?

Vapor phase reflow is a soldering technique that uses a hot vapor blanket generated by a boiling heat transfer liquid to provide uniform and efficient heat transfer to the PCB assembly. It differs from conventional reflow methods, such as convection and IR reflow, in that it provides a more uniform heating environment and reduces the risk of thermal damage to components. -

What are the main advantages of using vapor phase reflow technology?

The main advantages of vapor phase reflow include uniform heat transfer, improved soldering quality, reduced energy consumption, and flexibility in board design. These advantages help manufacturers address the challenges posed by the increasing complexity and density of modern electronic assemblies. -

What industries and product categories can benefit from vapor phase reflow technology?

Vapor phase reflow technology has found applications in various industries, including consumer electronics, automotive electronics, medical devices, aerospace and defense, and industrial electronics. It is particularly beneficial for products with high component densities, fine-pitch components, and sensitive components that require uniform heating and precise temperature control. -

What equipment is needed to implement vapor phase reflow technology?

To implement vapor phase reflow technology, manufacturers need a vapor phase reflow oven, a conveyor system, a cooling station, and a fume extraction system. The vapor phase reflow oven consists of a tank filled with a heat transfer liquid, heating elements, and a condensation coil to control the vapor blanket height. -

How can manufacturers optimize and control the vapor phase reflow process?

To optimize and control the vapor phase reflow process, manufacturers need to carefully set and monitor key process parameters, such as preheat temperature and time, vapor temperature, dwell time, and cooling rate. Process monitoring and data logging systems can be used to provide real-time feedback on the temperature profile and other key variables, allowing manufacturers to fine-tune the process and ensure consistent results across different PCB assemblies and production runs.

Conclusion

Vapor phase reflow technology has emerged as a powerful solution for addressing the challenges posed by the increasing complexity and density of modern electronic assemblies. By providing a uniform and efficient heating environment, vapor phase reflow ensures consistent solder joint quality, reduces the risk of thermal damage to components, and offers greater flexibility in board design.

As the electronics industry continues to evolve, with ever-increasing demands for performance, reliability, and sustainability, vapor phase reflow technology is poised to play an increasingly important role in the manufacturing of high-quality electronic products. By investing in vapor phase reflow equipment and optimizing their processes, manufacturers can improve their product quality, reduce their environmental impact, and stay competitive in a rapidly changing market.

| Parameter | Description | Typical Value Range |

|---|---|---|

| Preheat Temperature | The temperature at which the PCB assembly is preheated to activate the flux and remove moisture | 150°C – 180°C |

| Preheat Time | The duration of the preheat stage | 60 – 120 seconds |

| Vapor Temperature | The temperature of the vapor blanket, which determines the maximum temperature the PCB assembly will reach during reflow | 230°C – 260°C |

| Dwell Time | The duration the PCB assembly spends in the vapor blanket | 60 – 120 seconds |

| Cooling Rate | The rate at which the PCB assembly is cooled after exiting the vapor blanket | 1°C – 4°C per second |

Table 1: Typical process parameters for vapor phase reflow

No responses yet