Introduction to PCB Assembly in China

China has emerged as a global leader in the electronics manufacturing industry, particularly in the field of printed circuit board (PCB) assembly. The country’s vast manufacturing capabilities, coupled with its skilled workforce and competitive pricing, have made it an attractive destination for businesses seeking high-quality PCB assembly services. In this article, we will explore the reasons why choosing PCB assembly in China can be a strategic decision for your business.

The Advantages of PCB Assembly in China

Cost-Effectiveness

One of the primary reasons why companies choose PCB assembly in China is the significant cost savings they can achieve. China’s lower labor costs, coupled with its efficient manufacturing processes and economies of scale, enable PCB assembly providers to offer competitive pricing without compromising on quality. This cost advantage allows businesses to reduce their production expenses and allocate resources to other critical areas of their operations.

Skilled Workforce

China boasts a highly skilled and experienced workforce in the electronics manufacturing industry. The country has invested heavily in technical education and training programs, producing a large pool of qualified engineers, technicians, and operators. These skilled professionals possess the knowledge and expertise necessary to handle complex PCB assembly projects, ensuring high-quality results and adherence to international standards.

Advanced Technology and Infrastructure

Chinese PCB assembly providers have access to state-of-the-art technology and advanced manufacturing facilities. They continuously invest in the latest equipment and automation systems to enhance production efficiency, accuracy, and consistency. From surface-mount technology (SMT) lines to automated optical inspection (AOI) systems, Chinese PCB assembly companies leverage cutting-edge tools to deliver superior products and meet the evolving needs of their clients.

Rapid Prototyping and Production

In today’s fast-paced business environment, time-to-market is crucial. Chinese PCB assembly providers understand this and have streamlined their processes to offer rapid prototyping and production services. They can quickly turn around prototypes, allowing businesses to test and refine their designs before committing to mass production. Additionally, China’s well-established supply chain and logistics infrastructure enable efficient and timely delivery of finished products to clients worldwide.

Flexibility and Customization

Chinese PCB assembly companies are known for their flexibility and willingness to accommodate custom requirements. Whether you need small-batch production for niche applications or large-scale manufacturing for high-volume orders, they can adapt their processes to meet your specific needs. Chinese providers are also experienced in handling a wide range of PCB types, including rigid, flexible, and rigid-flex boards, as well as various surface finishes and component packages.

Choosing the Right PCB Assembly Partner in China

While China offers numerous benefits for PCB assembly, it is essential to select the right partner to ensure a successful collaboration. Here are some key factors to consider when choosing a PCB assembly provider in China:

Quality Assurance

Ensure that the PCB assembly provider has robust quality assurance processes in place. Look for certifications such as ISO 9001, ISO 14001, and IATF 16949, which demonstrate their commitment to quality management and environmental responsibility. Inquire about their testing and inspection procedures, including in-circuit testing (ICT), functional testing, and AOI, to verify the reliability and performance of the assembled PCBs.

Technical Expertise and Support

Assess the technical expertise and support offered by the PCB assembly provider. They should have a team of experienced engineers who can provide guidance and assistance throughout the design and manufacturing process. Look for providers that offer design for manufacturability (DFM) analysis and feedback to optimize your PCB design for production. Additionally, consider their ability to provide technical support and troubleshooting services post-production.

Communication and Language Proficiency

Effective communication is crucial when working with an overseas PCB assembly partner. Choose a provider with English-speaking staff or dedicated project managers who can communicate clearly and promptly. Ensure that they have established communication channels, such as email, video conferencing, and instant messaging, to facilitate regular updates and address any concerns or questions you may have.

Intellectual Property Protection

Protecting your intellectual property (IP) is paramount when outsourcing PCB assembly to China. Look for providers that have strict IP protection policies and non-disclosure agreements (NDAs) in place. Inquire about their measures to safeguard your sensitive information, such as secure data storage, access controls, and employee confidentiality agreements. Reputable PCB assembly companies understand the importance of IP protection and take necessary steps to maintain the confidentiality of your designs and proprietary information.

Lead Time and Delivery

Consider the lead time and delivery capabilities of the PCB assembly provider. They should have a proven track record of meeting project deadlines and delivering products on time. Inquire about their manufacturing capacity and ability to handle your production volume. Additionally, assess their shipping and logistics arrangements to ensure smooth and efficient delivery of your assembled PCBs.

PCB Assembly Process in China

To better understand the PCB assembly process in China, let’s take a closer look at the key steps involved:

-

Design and Prototyping: The process begins with the PCB design phase, where the client provides the schematic diagram and bill of materials (BOM). The Chinese PCB assembly provider reviews the design and offers DFM feedback to optimize it for manufacturing. Once the design is finalized, prototypes are fabricated and tested to validate the functionality and performance of the PCB.

-

Component Sourcing: The PCB assembly provider sources the required components based on the BOM. They have established relationships with reliable component suppliers and can often secure competitive pricing due to their high-volume purchases. The components are carefully inspected to ensure they meet the required specifications and quality standards.

-

PCB Fabrication: The bare PCBs are fabricated according to the approved design. This involves creating the copper traces, drilling holes, applying solder mask, and adding silkscreen markings. The fabricated PCBs undergo rigorous quality checks to verify their dimensional accuracy, electrical continuity, and overall integrity.

-

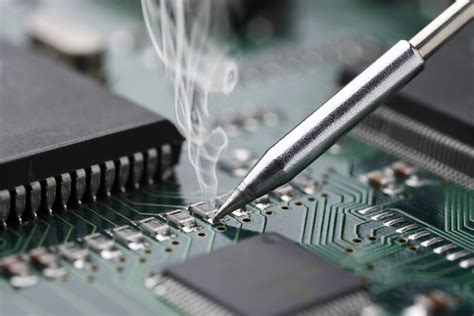

Surface Mount Assembly (SMT): The SMT process involves placing and soldering surface-mount components onto the PCB. The PCBs are loaded onto the SMT Line, where automated pick-and-place machines accurately place the components based on the programmed coordinates. The boards then pass through a reflow oven, where the solder paste melts and forms reliable electrical connections between the components and the PCB pads.

-

Through-Hole Assembly (THT): If the PCB design includes through-hole components, they are manually inserted into the designated holes on the board. The leads of the components are then soldered to the pads on the opposite side of the PCB using wave soldering or selective soldering techniques.

-

Inspection and Testing: After the assembly process, the PCBs undergo thorough inspection and testing to ensure their quality and functionality. This includes visual inspection, automated optical inspection (AOI), in-circuit testing (ICT), and functional testing. Any defects or issues identified during this stage are rectified before the PCBs are approved for final packaging.

-

Packaging and Shipping: The assembled PCBs are carefully packaged to protect them during transit. The packaging materials are chosen based on the specific requirements of the client and the shipping method. The PCBs are then shipped to the client’s designated location using reliable logistics partners.

FAQs about PCB Assembly in China

Q1: What is the minimum order quantity (MOQ) for PCB assembly in China?

A1: The minimum order quantity for PCB assembly in China varies among providers. Some companies offer low MOQs, even as low as 1-10 pieces for prototyping, while others may require higher quantities for mass production. It’s best to discuss your specific requirements with potential PCB assembly partners to determine their MOQ policies.

Q2: How long does it take to complete a PCB assembly project in China?

A2: The lead time for PCB assembly in China depends on several factors, such as the complexity of the design, the availability of components, and the production volume. On average, prototyping can take anywhere from a few days to a couple of weeks, while mass production lead times can range from several weeks to a few months. It’s important to communicate your timeline requirements with the PCB assembly provider and plan accordingly.

Q3: Can Chinese PCB assembly providers source components on my behalf?

A3: Yes, most Chinese PCB assembly providers offer component sourcing services. They have established relationships with reliable component suppliers and can procure the necessary components based on your bill of materials (BOM). This can be a convenient option, especially if you are unfamiliar with the local supply chain or want to leverage the provider’s purchasing power for better pricing.

Q4: How can I ensure the quality of the PCBs assembled in China?

A4: To ensure the quality of PCBs assembled in China, choose a provider with a robust quality management system and certifications such as ISO 9001. Discuss their quality assurance processes, including testing and inspection procedures, and request documentation such as quality reports and test results. Additionally, consider conducting on-site audits or requesting third-party inspections to verify the quality of the assembled PCBs.

Q5: What is the typical payment terms for PCB assembly services in China?

A5: Payment terms for PCB assembly services in China can vary depending on the provider and the nature of the project. Common payment terms include 30% deposit upon order placement and the remaining 70% balance before shipment. Some providers may offer more flexible terms, such as milestone payments or credit terms for established clients. It’s important to clarify the payment terms and conditions with the PCB assembly provider before entering into a contract.

Conclusion

China has established itself as a global hub for PCB assembly, offering numerous advantages for businesses seeking high-quality, cost-effective, and efficient Electronics Manufacturing Services. From its skilled workforce and advanced technology to its rapid prototyping and flexible customization capabilities, China provides a compelling value proposition for PCB assembly.

When choosing a PCB assembly partner in China, it’s crucial to consider factors such as quality assurance, technical expertise, communication proficiency, IP protection, and delivery reliability. By carefully evaluating potential providers and selecting the right partner, you can leverage the benefits of PCB assembly in China to enhance your product quality, reduce costs, and accelerate your time-to-market.

As the electronics industry continues to evolve and grow, China’s PCB assembly sector is well-positioned to meet the increasing demands and challenges of the market. By partnering with a reputable Chinese PCB assembly provider, you can tap into their expertise, capabilities, and resources to drive innovation, competitiveness, and success in your electronics manufacturing endeavors.

No responses yet