What are Gerber Files and Why are They Important?

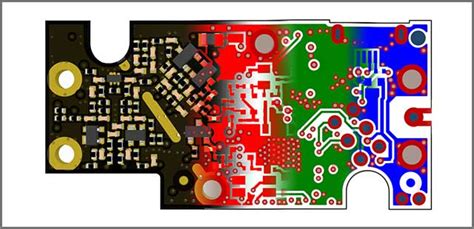

Gerber files are the standard file format used in the PCB (printed circuit board) industry to describe the printed circuit board images (copper layers, solder mask, legend, etc.) used to manufacture a PCB. Developed by Gerber Systems Corp., a division of Ucamco, Gerber files provide a precise and efficient way to transfer PCB design data from CAD systems to PCB fabrication equipment.

Gerber files are essential because they contain all the necessary information for a PCB manufacturer to fabricate your board exactly to your specifications. Inaccurate or incomplete Gerber files can lead to manufacturing issues, delays, and added costs. Therefore, it’s crucial to ensure your Gerber files are correctly generated and contain all the required information before sending them to your PCB manufacturer.

The 9 Key Considerations for Gerber File Output

When generating Gerber files for PCB manufacturing, there are 9 key areas you need to pay close attention to in order to ensure smooth and accurate fabrication of your PCB design:

- File Format and Naming Conventions

- Copper Layer Considerations

- Solder Mask and Silkscreen

- Drill Files and Hole Sizes

- Apertures and Tooling Holes

- Panelization and Board Outline

- Netlist and Test Point Files

- Layer Stackup Information

- Design Rule Checks (DRC)

Let’s dive into each of these areas in more detail.

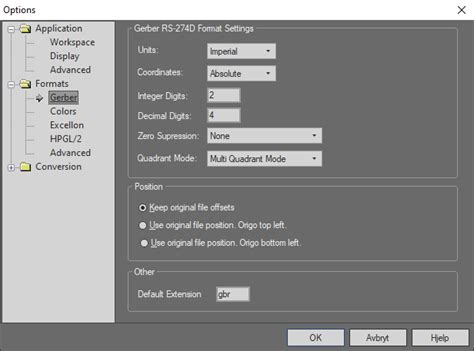

1. File Format and Naming Conventions

Gerber files should be generated in RS-274X format, also known as Extended Gerber or X-Gerber. This is the current industry standard and ensures compatibility with modern PCB fabrication equipment. Avoid using obsolete formats like RS-274-D.

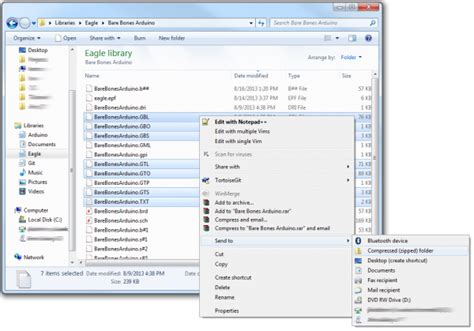

Use clear and consistent naming conventions for your Gerber files. Each file should be named according to its layer function, such as:

| Layer Function | Suggested Filename |

|---|---|

| Top Copper | projectname.GTL |

| Bottom Copper | projectname.GBL |

| Top Soldermask | projectname.GTS |

| Bottom Soldermask | projectname.GBS |

| Top Silkscreen | projectname.GTO |

| Bottom Silkscreen | projectname.GBO |

| Board Outline | projectname.GKO |

| Drill File | projectname.TXT |

Using a clear naming scheme helps avoid confusion and ensures your manufacturer can easily identify each file.

2. Copper Layer Considerations

Ensure that your copper features (traces, pads, polygons) meet your manufacturer’s minimum width and spacing requirements. These requirements depend on the PCB fabrication process and the desired copper weight.

| Copper Weight (oz) | Minimum Track Width (mm) | Minimum Spacing (mm) |

|---|---|---|

| 0.5 | 0.10 | 0.10 |

| 1 | 0.15 | 0.15 |

| 2 | 0.20 | 0.20 |

Include copper thieving if your design has large copper pour areas. Copper thieving helps ensure even copper distribution and prevents issues like copper pooling or solder mask adhesion problems.

3. Solder Mask and Silkscreen

Solder mask and silkscreen layers should be generated as separate Gerber files. Ensure that the solder mask openings are slightly larger than the copper pads to allow for proper solder wetting. A typical Solder Mask Expansion is 0.05mm to 0.075mm.

Silkscreen features should have a minimum line width of 0.15mm and a minimum spacing of 0.15mm to ensure legibility. Avoid placing silkscreen over exposed copper areas like pads or vias.

4. Drill Files and Hole Sizes

Drill files should be generated in Excellon format and include all the necessary hole information (position, size, and plating). Ensure that your hole sizes meet your manufacturer’s minimum drill size requirements.

| Hole Type | Minimum Hole Size (mm) |

|---|---|

| Through Hole | 0.20 |

| Micro Via | 0.10 |

If your design includes blind or buried vias, provide clear layer stackup information to your manufacturer.

5. Apertures and Tooling Holes

Gerber files should include all necessary aperture information. Use D-Codes to define aperture shapes and sizes. Avoid creating custom apertures unless absolutely necessary.

Include tooling holes in your design to help with PCB alignment during fabrication and assembly. Tooling holes should be at least 2.5mm in diameter and placed near the corners of the board.

6. Panelization and Board Outline

If your design requires panelization, include the panel outline and any necessary fiducial marks in your Gerber files. Clearly communicate your panelization requirements to your manufacturer.

The board outline should be defined in a separate layer and should include any required cutouts or slots. Ensure that your board outline meets your manufacturer’s minimum routing requirements, typically 1.5mm to 2mm.

7. Netlist and Test Point Files

Provide a netlist file (IPC-D-356 format) to help your manufacturer verify the continuity of your PCB design. This helps catch any potential issues before fabrication.

If your design requires electrical testing, include a test point file that specifies the location and type of test points. This information helps your manufacturer set up the appropriate testing procedures.

8. Layer Stackup Information

Provide clear layer stackup information to your manufacturer, specifying the number of layers, layer order, copper weights, and dielectric material requirements. This information is crucial for ensuring the correct fabrication of your PCB.

Example 4-layer stackup:

| Layer | Material | Thickness (mm) | Copper Weight (oz) |

|——-|———-|—————-|———————|

| Top Copper | FR-4 | 0.035 | 1 |

| Inner Layer 1 | FR-4 | 0.2 | 0.5 |

| Inner Layer 2 | FR-4 | 0.2 | 0.5 |

| Bottom Copper | FR-4 | 0.035 | 1 |

9. Design Rule Checks (DRC)

Before generating your Gerber files, run a comprehensive Design Rule Check (DRC) on your PCB design. This helps identify any potential design issues, such as trace width or spacing violations, missing or incorrect connections, or silk screen overlaps.

Resolve any DRC errors before generating your final Gerber files. This step can save you significant time and cost by catching design issues early in the process.

FAQ

-

What is the difference between Gerber files and ODB++ files?

Gerber files and ODB++ (Open Database++) files are both used to transfer PCB design data to manufacturers. However, ODB++ is a more comprehensive format that includes not only the layer images but also netlist, component placement, and drill data in a single database. Gerber files, on the other hand, are individual files for each layer and require separate drill and netlist files. -

Can I use different copper weights on different layers of my PCB?

Yes, you can use different copper weights on different layers of your PCB. This is often done to achieve specific electrical or thermal characteristics. However, make sure to clearly communicate your copper weight requirements for each layer to your manufacturer. -

What is the purpose of including fiducial marks in my Gerber files?

Fiducial marks are used as reference points for aligning the various layers of your PCB during fabrication and assembly. They help ensure the accurate registration of layers and the precise placement of components. Fiducial marks are especially important for designs with tight tolerances or high-density components. -

How do I ensure my solder mask openings are the correct size?

To ensure your solder mask openings are the correct size, specify the desired solder mask expansion in your Gerber files. A typical solder mask expansion is 0.05mm to 0.075mm larger than the copper pad size. Your CAD software should have settings to control the solder mask expansion when generating Gerber files. -

What should I do if my manufacturer reports issues with my Gerber files?

If your manufacturer reports issues with your Gerber files, first verify that you have followed all the necessary guidelines for generating accurate files (file format, naming conventions, DRC, etc.). If the issues persist, work closely with your manufacturer to identify the specific problems and make the necessary corrections to your design or Gerber files. Maintain clear communication and be prepared to provide additional information or files if requested.

Conclusion

Generating accurate and complete Gerber files is crucial for ensuring the smooth and successful fabrication of your PCB design. By paying close attention to the 9 key areas outlined in this article – file format and naming, copper layers, solder mask and silkscreen, drill files, apertures, panelization, netlist and test points, layer stackup, and DRC – you can minimize the risk of manufacturing issues and delays.

Remember to always communicate clearly with your PCB manufacturer and provide them with all the necessary information and files they need to fabricate your design to your specifications. By following these guidelines and best practices, you can streamline your PCB fabrication process and achieve the best possible results for your projects.

No responses yet