Understanding PCB Resonances and Their Impact on Circuit Performance

Printed Circuit Boards (PCBs) are essential components in modern electronic devices, providing a platform for mounting and interconnecting electronic components. One of the critical aspects of PCB design is managing power plane resonances, which can significantly impact the overall performance and reliability of the circuit. In this article, we will dive deep into the topic of PCB power plane resonances, exploring when they occur, their causes, and strategies to mitigate their effects.

What are PCB Power Plane Resonances?

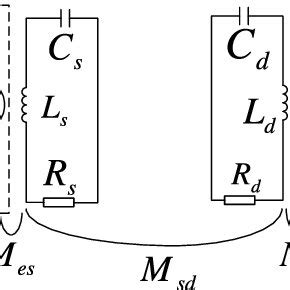

PCB power plane resonances are electromagnetic phenomena that occur when the power and ground planes of a PCB interact with each other, creating standing waves at specific frequencies. These resonances can lead to voltage fluctuations, signal integrity issues, and electromagnetic interference (EMI) problems, compromising the performance and reliability of the electronic circuit.

The Role of Power and Ground Planes in PCBs

Power and ground planes are crucial elements in PCB design, serving as low-impedance paths for distributing power and providing a reference for signals. These planes are typically made of copper and are placed on dedicated layers within the PCB stack-up. The power plane supplies the necessary voltage to the components, while the ground plane acts as a return path for the current.

Factors Contributing to PCB Power Plane Resonances

Several factors can contribute to the occurrence of PCB power plane resonances:

-

Plane Geometry: The shape and size of the power and ground planes play a significant role in determining the resonant frequencies. Rectangular planes, for example, are more susceptible to resonances compared to irregular shapes.

-

Dielectric Material: The dielectric material used in the PCB, which separates the power and ground planes, affects the resonant frequencies. The dielectric constant and thickness of the material influence the capacitance between the planes, which in turn impacts the resonant behavior.

-

Plane Spacing: The distance between the power and ground planes, known as the plane spacing, also influences the resonant frequencies. Closer spacing leads to higher capacitance and lower resonant frequencies, while larger spacing results in lower capacitance and higher resonant frequencies.

-

Plane Perforations: Perforations in the power and ground planes, such as via holes and component mounting holes, can disrupt the current flow and create localized resonances. The size, shape, and location of these perforations affect the resonant behavior.

-

Component Placement: The placement of components on the PCB can also impact power plane resonances. Components with high current consumption or fast switching speeds can excite resonances, especially if they are located near the edges of the planes or in areas with high perforation density.

Identifying and Analyzing PCB Power Plane Resonances

To effectively address PCB power plane resonances, it is essential to identify and analyze their occurrence. Several methods can be employed for this purpose:

Frequency Domain Analysis

Frequency domain analysis involves measuring the impedance of the power distribution network (PDN) over a range of frequencies. This can be done using a vector network analyzer (VNA) or by simulating the PDN using electromagnetic (EM) simulation tools. The resulting impedance plot reveals the resonant frequencies, allowing designers to identify potential issues.

Time Domain Analysis

Time domain analysis focuses on examining the voltage and current waveforms in the time domain. Oscilloscope measurements or time-domain reflectometry (TDR) techniques can be used to capture the waveforms and identify any voltage fluctuations or ringing that may indicate the presence of resonances.

Electromagnetic Simulation

Electromagnetic simulation tools, such as 3D EM solvers, can be used to model and analyze the PCB power plane resonances. These tools solve Maxwell’s equations to predict the electromagnetic behavior of the PCB, including the resonant frequencies and field distributions. Simulation allows designers to explore different design options and optimize the PCB layout to minimize resonances.

Strategies for Mitigating PCB Power Plane Resonances

Once the PCB power plane resonances are identified and analyzed, several strategies can be employed to mitigate their effects:

Optimizing Plane Geometry

Modifying the shape and size of the power and ground planes can help reduce the impact of resonances. Irregular plane shapes, such as rounded corners or cutouts, can disrupt the standing wave patterns and shift the resonant frequencies. Additionally, minimizing the plane area and using multiple smaller planes instead of a single large plane can also help mitigate resonances.

Adjusting Dielectric Material and Thickness

The choice of dielectric material and its thickness plays a crucial role in managing power plane resonances. Using materials with lower dielectric constants and increasing the dielectric thickness can help reduce the capacitance between the planes, shifting the resonant frequencies to higher values. This can be particularly effective in high-speed designs where resonances at higher frequencies are less likely to interfere with the signal integrity.

Implementing Plane Cutouts and Splits

Introducing strategically placed cutouts or splits in the power and ground planes can help disrupt the current flow and break up the resonant patterns. These modifications can be in the form of slots, holes, or isolated islands. By carefully designing these cutouts, designers can effectively mitigate the impact of resonances on the circuit performance.

Utilizing Decoupling Capacitors

Decoupling capacitors are commonly used to suppress power plane resonances and provide a stable power supply to the components. These capacitors are placed close to the power pins of the components and act as local energy storage, providing a low-impedance path for high-frequency currents. Properly selecting the capacitor values and optimizing their placement can significantly reduce the impact of resonances.

Implementing Power Plane Stitching Vias

Power plane stitching vias are conductive connections between the power and ground planes that help equalize the potential difference and reduce the impedance between the planes. By placing stitching vias at strategic locations, such as near the edges of the planes or in areas with high perforation density, designers can effectively suppress resonances and improve the power integrity of the PCB.

Real-World Examples and Case Studies

To illustrate the impact of PCB power plane resonances and the effectiveness of mitigation strategies, let’s consider a few real-world examples and case studies.

Example 1: High-Speed Digital Design

In a high-speed digital design, such as a high-performance processor or an FPGA board, power plane resonances can significantly impact the signal integrity and cause issues like voltage fluctuations, jitter, and crosstalk. By implementing a combination of strategies, such as optimizing the plane geometry, using low-dielectric materials, and placing decoupling capacitors near the critical components, designers can effectively mitigate the resonances and ensure reliable operation of the digital circuits.

Example 2: Automotive Electronics

Automotive electronics, such as engine control units (ECUs) and infotainment systems, are subject to stringent EMI requirements to ensure the reliability and safety of the vehicle. Power plane resonances can contribute to EMI emissions, potentially interfering with other electronic systems in the vehicle. By employing techniques like plane cutouts, stitching vias, and proper grounding practices, automotive electronics designers can minimize the impact of resonances and meet the necessary EMI standards.

Example 3: Wireless Communication Devices

In wireless communication devices, such as smartphones or IoT devices, power plane resonances can affect the performance of the radio frequency (RF) circuits. Resonances can cause unwanted coupling between the power planes and the RF signals, leading to degraded signal quality and reduced range. By carefully designing the power distribution network, using shielding techniques, and implementing filtering components, designers can mitigate the impact of resonances on the RF performance of the device.

Frequently Asked Questions (FAQ)

-

What are the main causes of PCB power plane resonances?

The main causes of PCB power plane resonances include plane geometry, dielectric material properties, plane spacing, perforations, and component placement. These factors contribute to the interaction between the power and ground planes, leading to the formation of standing waves at specific frequencies. -

How can I identify PCB power plane resonances in my design?

PCB power plane resonances can be identified through frequency domain analysis, time domain analysis, and electromagnetic simulation. Frequency domain analysis involves measuring the impedance of the power distribution network, while time domain analysis examines voltage and current waveforms. Electromagnetic simulation tools can model and predict the resonant behavior of the PCB. -

What are some effective strategies for mitigating PCB power plane resonances?

Effective strategies for mitigating PCB power plane resonances include optimizing plane geometry, adjusting dielectric material and thickness, implementing plane cutouts and splits, utilizing decoupling capacitors, and implementing power plane stitching vias. These techniques help disrupt the resonant patterns, reduce the impedance between the planes, and provide a stable power supply to the components. -

How can decoupling capacitors help in suppressing power plane resonances?

Decoupling capacitors act as local energy storage and provide a low-impedance path for high-frequency currents. By placing decoupling capacitors close to the power pins of the components, designers can effectively suppress power plane resonances and ensure a stable power supply. The capacitors help to filter out the high-frequency noise and prevent it from propagating throughout the PCB. -

Are there any specific considerations for mitigating power plane resonances in high-speed designs?

In high-speed designs, power plane resonances can have a significant impact on signal integrity. To mitigate resonances in high-speed designs, designers should focus on optimizing the plane geometry, using low-dielectric materials, and implementing effective decoupling strategies. Additionally, techniques like differential signaling, proper termination, and careful routing can help minimize the impact of resonances on the high-speed signals.

Conclusion

PCB power plane resonances are a critical consideration in PCB design, as they can significantly impact the performance, reliability, and EMI characteristics of electronic circuits. Understanding when these resonances occur, their causes, and the strategies to mitigate their effects is essential for designers to create robust and reliable PCBs.

By employing techniques such as optimizing plane geometry, adjusting dielectric properties, implementing plane cutouts and stitching vias, and utilizing decoupling capacitors, designers can effectively manage power plane resonances and ensure the proper functioning of their circuits. Additionally, using frequency domain analysis, time domain analysis, and electromagnetic simulation tools can help identify and analyze resonances, enabling designers to make informed decisions and optimize their designs.

As the complexity and speed of electronic systems continue to increase, the importance of addressing PCB power plane resonances becomes even more critical. By staying up-to-date with the latest design techniques and best practices, PCB designers can overcome the challenges posed by resonances and deliver high-performance, reliable, and EMI-compliant electronic products.

No responses yet