Understanding Solder Mask Expansion

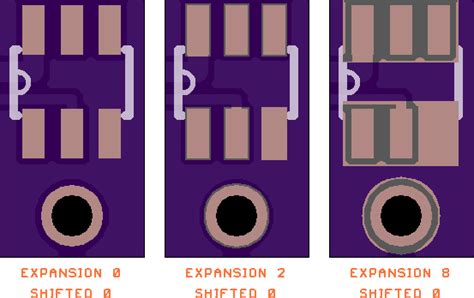

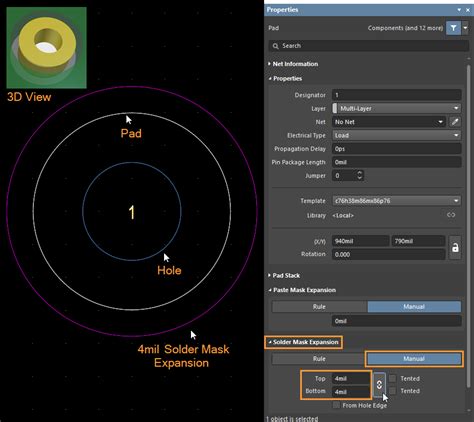

Solder mask expansion refers to the amount by which the solder mask opening is larger than the copper pad it surrounds. This expansion is necessary to account for any misalignment or registration errors during the manufacturing process. If the solder mask opening is too small, it may encroach on the copper pad and hinder solderability. On the other hand, if the opening is too large, it can lead to solder bridging between adjacent pads.

The solder mask expansion value is typically expressed in mils (thousandths of an inch) or microns. It is the distance between the edge of the copper pad and the edge of the solder mask opening.

Factors Affecting Solder Mask Expansion Choice

Several factors influence the selection of an appropriate solder mask expansion value:

PCB Manufacturing Capabilities

The manufacturing capabilities of your PCB fabricator play a significant role in determining the solder mask expansion value. More advanced PCB manufacturers can achieve tighter tolerances and registration accuracy, allowing for smaller solder mask expansion values. It’s essential to discuss your requirements with your manufacturer and understand their capabilities before finalizing your design.

Component Pitch and Density

The pitch and density of components on your PCB also affect the choice of solder mask expansion. For high-density designs with fine-pitch components, smaller solder mask expansion values are necessary to prevent solder bridging. In contrast, larger expansion values may be acceptable for designs with larger components and greater spacing between pads.

Soldermask Type and Application Method

The type of solder mask material and the application method used by your manufacturer can influence the expansion value. Liquid photoimageable (LPI) solder masks, which are widely used in the industry, typically require smaller expansion values compared to dry film solder masks. The application method, such as spraying or curtain coating, can also impact the registration accuracy and, consequently, the expansion value.

IPC Standards and Recommendations

The IPC (Association Connecting Electronics Industries) provides guidelines and recommendations for solder mask expansion values based on the component pitch and the solder mask type. These standards, such as IPC-SM-840 and IPC-7351, offer valuable guidance for designers and manufacturers. Adhering to these standards ensures compatibility and reliability in the final product.

Recommended Solder Mask Expansion Values

The following table provides general recommendations for solder mask expansion values based on component pitch and solder mask type:

| Component Pitch | Solder Mask Type | Recommended Expansion Value |

|---|---|---|

| ≥ 0.65 mm | LPI | 50-75 μm (2-3 mils) |

| 0.5 mm – 0.65 mm | LPI | 25-50 μm (1-2 mils) |

| 0.4 mm – 0.5 mm | LPI | 25 μm (1 mil) |

| < 0.4 mm | LPI | Consult manufacturer |

| ≥ 0.65 mm | Dry Film | 75-100 μm (3-4 mils) |

| 0.5 mm – 0.65 mm | Dry Film | 50-75 μm (2-3 mils) |

| < 0.5 mm | Dry Film | Consult manufacturer |

These values serve as a starting point, and it’s crucial to discuss your specific requirements with your PCB manufacturer to ensure optimal results.

Impact of Solder Mask Expansion on PCB Performance

Choosing the right solder mask expansion value has a direct impact on the performance and reliability of your PCB:

Solderability

An appropriate solder mask expansion value ensures good solderability by providing sufficient exposed copper area for solder to wet and form a reliable connection. If the expansion value is too small, the solder mask may encroach on the copper pad, hindering solder wetting and leading to poor joint formation.

Solder Bridging Prevention

Solder bridging occurs when solder inadvertently connects adjacent pads, causing short circuits and potentially damaging the PCB or connected components. By selecting an appropriate solder mask expansion value, you can minimize the risk of solder bridging. The solder mask acts as a barrier, preventing solder from spreading beyond the intended pad area.

Adhesion and Durability

The solder mask expansion value also affects the adhesion and durability of the solder mask layer. If the expansion value is too large, there may be insufficient overlap between the solder mask and the copper pad, leading to poor adhesion. This can result in the solder mask lifting or peeling off during the soldering process or in harsh environmental conditions. Ensuring an appropriate expansion value promotes good adhesion and long-term durability of the solder mask.

Design Considerations for Solder Mask Expansion

When designing your PCB, keep the following considerations in mind regarding solder mask expansion:

Pad Size and Shape

The size and shape of your component pads influence the solder mask expansion value. Larger pads generally require larger expansion values to ensure sufficient clearance. Irregularly shaped pads, such as those with rounded corners or chamfers, may need special attention to ensure proper solder mask coverage.

Soldermask Webbing

Soldermask webbing refers to the thin solder mask bridge between adjacent pads. It is essential to maintain a minimum webbing width to ensure the structural integrity of the solder mask and prevent solder bridging. The webbing width depends on the solder mask expansion value and the spacing between pads. Consult your PCB manufacturer for their recommended minimum webbing width based on your design parameters.

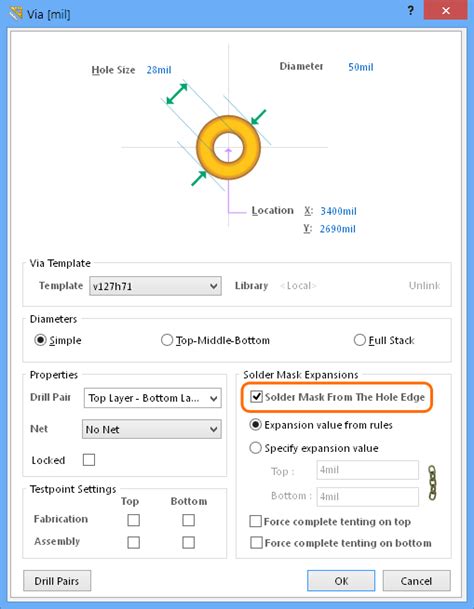

Thermal Pads and Via Tenting

Thermal pads, used for heat dissipation, and via tenting, where the solder mask covers the via holes, require special consideration when determining the solder mask expansion value. Thermal pads often require larger expansion values to ensure proper heat transfer and prevent solder mask interference. Via tenting may require smaller expansion values to prevent solder mask from seeping into the via holes during the application process.

FAQ

-

Q: What happens if I choose a solder mask expansion value that is too small?

A: If the solder mask expansion value is too small, the solder mask may encroach on the copper pad, hindering solder wetting and leading to poor joint formation. This can result in solderability issues and potentially affect the reliability of the PCB. -

Q: Can I use different solder mask expansion values for different components on the same PCB?

A: Yes, it is possible to use different solder mask expansion values for different components or areas of the PCB. This is particularly useful when you have components with varying pitches or densities. However, it’s important to clearly communicate these requirements to your PCB manufacturer to ensure proper implementation. -

Q: How do I determine the right solder mask expansion value for my PCB design?

A: To determine the right solder mask expansion value, consider factors such as your PCB manufacturer’s capabilities, component pitch and density, solder mask type and application method, and relevant IPC standards. Consult with your PCB manufacturer and refer to the recommended values based on your specific design parameters. -

Q: What are the consequences of using a solder mask expansion value that is too large?

A: If the solder mask expansion value is too large, it can lead to several issues. Solder bridging may occur between adjacent pads, causing short circuits. Additionally, there may be insufficient overlap between the solder mask and the copper pad, resulting in poor adhesion and potential lifting or peeling of the solder mask. -

Q: Can the choice of solder mask expansion value affect the cost of PCB manufacturing?

A: Yes, the choice of solder mask expansion value can indirectly affect the cost of PCB manufacturing. Smaller expansion values require tighter tolerances and higher registration accuracy, which may increase manufacturing costs. It’s essential to find a balance between the required performance and the associated manufacturing costs. Discuss your requirements and budget with your PCB manufacturer to find the most cost-effective solution.

Conclusion

Selecting the appropriate solder mask expansion value is a critical aspect of PCB design. It ensures proper solderability, prevents solder bridging, and promotes the overall reliability and durability of the PCB. By considering factors such as manufacturing capabilities, component pitch and density, solder mask type, and IPC standards, you can make an informed decision when choosing the solder mask expansion value for your design.

Remember to collaborate closely with your PCB manufacturer throughout the design process. They can provide valuable insights and recommendations based on their experience and capabilities. By working together and carefully considering the solder mask expansion value, you can create high-quality PCBs that meet your performance and reliability requirements.

No responses yet