Introduction to Heatsink paste

Heatsink paste, also known as thermal paste, thermal compound, or thermal grease, is a crucial component in ensuring efficient heat transfer between a heat-generating device, such as a CPU or GPU, and its heatsink. The primary purpose of heatsink paste is to fill the microscopic gaps and irregularities between the surfaces of the heat source and the heatsink, thereby improving thermal conductivity and overall cooling performance.

The Importance of Heatsink Paste

Without heatsink paste, the imperfections on the surfaces of the heat source and heatsink would create air pockets, which act as thermal insulators. These air pockets significantly hinder the transfer of heat, leading to increased temperatures and potentially causing damage to the device. By applying a thin layer of heatsink paste, you can eliminate these air gaps and ensure optimal heat dissipation.

Types of Heatsink Paste

There are several types of heatsink paste available on the market, each with its own unique properties and performance characteristics. The most common types include:

- Silicone-based pastes

- Metal-based pastes

- Carbon-based pastes

- Liquid metal pastes

- Ceramic-based pastes

We will discuss each type in more detail in the following sections.

Silicone-based Heatsink Pastes

Silicone-based heatsink pastes are among the most popular and widely used thermal compounds. They are known for their ease of application, non-conductive properties, and decent thermal performance.

Composition and Properties

Silicone-based pastes typically consist of a silicone oil or compound mixed with thermally conductive particles, such as zinc oxide or aluminum oxide. The silicone base provides a stable and non-conductive medium, while the added particles enhance the thermal conductivity of the paste.

Advantages

- Non-conductive and electrically insulating, reducing the risk of short circuits

- Easy to apply and remove

- Relatively inexpensive compared to other types of heatsink paste

- Suitable for most everyday applications

Disadvantages

- Lower thermal conductivity compared to metal-based or liquid metal pastes

- May dry out or degrade over time, requiring reapplication

Popular Silicone-based Heatsink Pastes

Some popular silicone-based heatsink pastes include:

- Arctic Silver 5

- Noctua NT-H1

- Thermal Grizzly Kryonaut

- Cooler Master MasterGel Maker

Metal-based Heatsink Pastes

Metal-based heatsink pastes offer higher thermal conductivity than silicone-based pastes, making them a popular choice for enthusiasts and overclockers who demand the best possible cooling performance.

Composition and Properties

Metal-based pastes contain a suspension of fine metal particles, such as silver, copper, or aluminum, in a liquid or semi-liquid base. These metal particles provide excellent thermal conductivity, allowing for more efficient heat transfer between the heat source and heatsink.

Advantages

- Higher thermal conductivity compared to silicone-based pastes

- Ideal for high-performance applications and overclocking

- Longer-lasting and more durable than silicone-based pastes

Disadvantages

- More expensive than silicone-based pastes

- Can be electrically conductive, requiring careful application to avoid short circuits

- May be more difficult to apply and remove compared to silicone-based pastes

Popular Metal-based Heatsink Pastes

Some well-known metal-based heatsink pastes include:

- Coollaboratory Liquid Ultra

- Thermal Grizzly Conductonaut

- Innovation Cooling Diamond

- Phobya Liquid Metal Paste

Carbon-based Heatsink Pastes

Carbon-based heatsink pastes are a relatively newer addition to the thermal compound market. They utilize carbon nanoparticles to enhance thermal conductivity while maintaining low electrical conductivity.

Composition and Properties

Carbon-based pastes contain carbon nanoparticles, such as carbon nanotubes or graphene, suspended in a non-conductive base. These nanoparticles offer excellent thermal conductivity while remaining electrically insulating.

Advantages

- High thermal conductivity, comparable to metal-based pastes

- Non-conductive and electrically insulating

- Stable performance over a wide temperature range

Disadvantages

- More expensive than silicone-based pastes

- May be more difficult to find compared to other types of heatsink paste

Popular Carbon-based Heatsink Pastes

Some examples of carbon-based heatsink pastes include:

- IC Graphite Thermal Pad

- Innovation Cooling Graphite Pad

- Thermal Grizzly Carbonaut

Liquid Metal Heatsink Pastes

Liquid metal heatsink pastes are the most thermally conductive option available, offering unparalleled heat transfer performance. However, they also come with some significant drawbacks that make them suitable only for advanced users.

Composition and Properties

Liquid metal pastes are composed of low-melting-point alloys, typically containing gallium, indium, and tin. These alloys remain in a liquid state at room temperature, allowing them to conform perfectly to the surfaces of the heat source and heatsink.

Advantages

- Highest thermal conductivity among all types of heatsink paste

- Ideal for extreme overclocking and high-performance applications

- Long-lasting and durable

Disadvantages

- Highly electrically conductive, requiring extreme caution during application to avoid short circuits

- Can be difficult to apply and remove

- May react with and permanently bond to aluminum heatsinks

- Expensive compared to other types of heatsink paste

Popular Liquid Metal Heatsink Pastes

Some well-known liquid metal heatsink pastes include:

- Thermal Grizzly Conductonaut

- Coollaboratory Liquid Pro

- Thermal Grizzly Hydronaut

Ceramic-based Heatsink Pastes

Ceramic-based heatsink pastes are known for their high thermal conductivity and electrical insulation properties. They provide a good balance between performance and ease of use.

Composition and Properties

Ceramic-based pastes contain ceramic particles, such as aluminum oxide or boron nitride, suspended in a non-conductive base. These ceramic particles offer good thermal conductivity while remaining electrically insulating.

Advantages

- Good thermal conductivity, higher than silicone-based pastes

- Non-conductive and electrically insulating

- Easy to apply and remove

- Stable performance over a wide temperature range

Disadvantages

- May be more expensive than silicone-based pastes

- Slightly lower thermal conductivity compared to metal-based or liquid metal pastes

Popular Ceramic-based Heatsink Pastes

Some examples of ceramic-based heatsink pastes include:

- Arctic Ceramique 2

- Noctua NT-H2

- Prolimatech PK-3

Comparison of Heatsink Paste Types

| Paste Type | Thermal Conductivity | Electrical Conductivity | Ease of Use | Price |

|---|---|---|---|---|

| Silicone-based | Moderate | Non-conductive | Easy | Low |

| Metal-based | High | Conductive | Moderate | High |

| Carbon-based | High | Non-conductive | Moderate | High |

| Liquid Metal | Very High | Highly Conductive | Difficult | Very High |

| Ceramic-based | High | Non-conductive | Easy | Moderate |

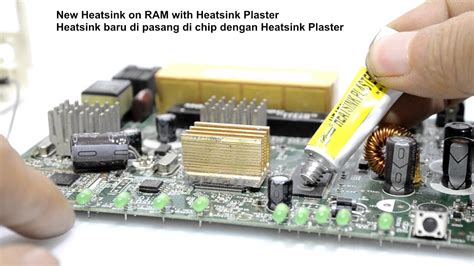

How to Apply Heatsink Paste

Applying heatsink paste correctly is crucial for achieving optimal thermal performance. Follow these steps to ensure a proper application:

-

Clean the surfaces of the heat source and heatsink using isopropyl alcohol and a lint-free cloth to remove any old thermal paste or residue.

-

Apply a small amount of heatsink paste to the center of the heat source. A pea-sized drop is usually sufficient.

-

Place the heatsink on top of the heat source and apply even pressure to spread the paste. The pressure will cause the paste to spread out and fill any gaps between the surfaces.

-

Secure the heatsink in place using the appropriate mounting mechanism, such as clips or screws.

-

Connect any necessary cables, such as the CPU fan or pump, and double-check all connections.

-

Power on the system and monitor temperatures to ensure proper cooling performance.

Frequently Asked Questions (FAQ)

-

Q: How often should I replace my heatsink paste?

A: In most cases, heatsink paste can last for several years without needing replacement. However, if you notice a significant increase in temperatures or if you remove the heatsink for any reason, it’s a good idea to clean off the old paste and apply a fresh layer. -

Q: Can I use too much heatsink paste?

A: Yes, applying too much heatsink paste can be detrimental to cooling performance. Excess paste can act as an insulator and prevent efficient heat transfer. Always follow the manufacturer’s instructions and apply a small amount, as a little goes a long way. -

Q: Is it okay to mix different types of heatsink paste?

A: No, it is not recommended to mix different types of heatsink paste. Each type of paste has its own unique composition and properties, and mixing them can lead to unpredictable results or even damage to your components. -

Q: Can I use heatsink paste on other components besides the CPU?

A: Yes, heatsink paste can be used on other components that require efficient heat transfer, such as GPUs, chipsets, or power regulators. However, always consult the manufacturer’s instructions or guidelines before applying paste to any component. -

Q: Are expensive heatsink pastes always better than cheaper options?

A: Not necessarily. While expensive heatsink pastes, such as liquid metal or high-end metal-based compounds, may offer the best thermal performance, they also come with higher risks and more difficult application processes. For most users, a good quality silicone-based or ceramic-based paste will provide sufficient cooling performance at a lower cost and with easier application.

Conclusion

Choosing the right heatsink paste is essential for ensuring optimal cooling performance and protecting your valuable components from heat-related damage. By understanding the different types of heatsink paste available, their compositions, advantages, and disadvantages, you can make an informed decision based on your specific needs and application.

Whether you opt for a silicone-based paste for ease of use and affordability, a metal-based or carbon-based paste for high performance, or a liquid metal paste for extreme overclocking, always follow proper application techniques and guidelines to achieve the best possible results.

Remember to monitor your system temperatures regularly and replace your heatsink paste as needed to maintain optimal cooling performance and extend the life of your components.

No responses yet