Understanding UL certification

What is UL Certification?

UL (Underwriters Laboratories) certification is a globally recognized safety standard for electrical and electronic products. It ensures that products meet rigorous safety requirements and are safe for use by consumers. UL certification is voluntary, but many manufacturers choose to obtain it to demonstrate their commitment to safety and quality.

Why is UL Certification Important?

UL certification is important for several reasons:

- Safety: UL certification ensures that products are safe for use and do not pose a risk of fire, electric shock, or other hazards.

- Compliance: Many jurisdictions require UL certification for certain types of products, such as electrical appliances and medical devices.

- Market Access: UL certification can help manufacturers access new markets and customers who require or prefer UL-certified products.

- Brand Reputation: Obtaining UL certification can enhance a manufacturer’s brand reputation and demonstrate their commitment to safety and quality.

Types of UL Certification

There are several types of UL certification, each with its own set of requirements and testing procedures. Some of the most common types of UL certification include:

| Certification Type | Description |

|---|---|

| UL Listed | Indicates that a product has been tested and meets UL’s safety standards for its intended use. |

| UL Recognized | Indicates that a component or material has been tested and meets UL’s safety standards for use in a specific product or application. |

| UL Classified | Indicates that a product has been evaluated for a specific hazard or performance characteristic, such as fire resistance or energy efficiency. |

Obtaining UL Certification

Steps to Obtain UL Certification

Obtaining UL certification involves several steps:

- Product Design: The manufacturer must design their product to meet UL’s safety standards and requirements.

- Testing: The product must undergo rigorous testing to ensure that it meets UL’s safety standards. This may include testing for fire resistance, electrical safety, and other hazards.

- Inspection: UL may conduct factory inspections to ensure that the manufacturer is following proper production and quality control procedures.

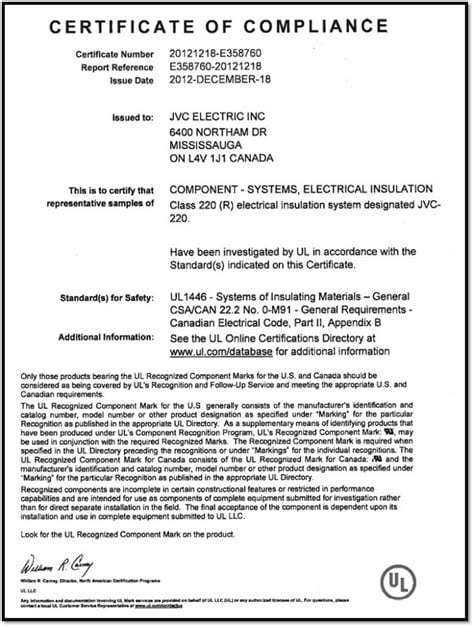

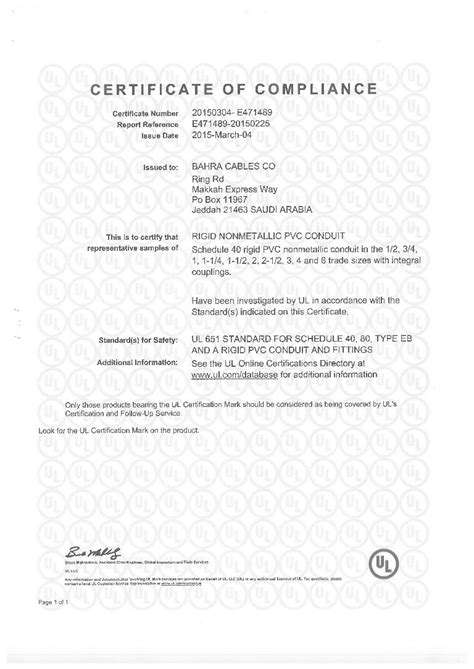

- Certification: If the product passes all tests and inspections, UL will issue a certificate of compliance and authorize the manufacturer to use the UL mark on their product.

Costs of UL Certification

The cost of UL certification can vary depending on several factors, such as the complexity of the product, the type of certification required, and the number of products being certified. Some of the costs associated with UL certification may include:

- Testing fees

- Inspection fees

- Certification fees

- Annual maintenance fees

Manufacturers should carefully consider the costs and benefits of UL certification before deciding whether to pursue it for their products.

Marking UL Certification on Circuit Boards

UL Marking Requirements

UL has specific requirements for marking certified products, including circuit boards. The UL mark must be clearly visible and legible on the product, and must include the following information:

- The UL symbol (either the UL Listed or UL Recognized mark)

- The manufacturer’s name or trademark

- The product model number or other identifying information

Methods for Marking UL Certification on Circuit Boards

There are several methods for marking UL certification on circuit boards, including:

- Silk Screening: The UL mark can be printed directly onto the circuit board using a silk screening process.

- Labeling: A separate label containing the UL mark can be affixed to the circuit board.

- Etching: The UL mark can be etched onto the circuit board using a chemical etching process.

- Laser Marking: The UL mark can be laser-engraved onto the circuit board.

The method chosen will depend on factors such as the size and material of the circuit board, the production volume, and the manufacturer’s preferences.

Placement of UL Mark on Circuit Boards

The placement of the UL mark on a circuit board is also important. The mark should be located in a visible and easily accessible location, such as near the edge of the board or on a separate label. It should not interfere with the function or operation of the circuit board.

Benefits of UL Certification for Circuit Boards

Obtaining UL certification for circuit boards can provide several benefits for manufacturers and consumers:

- Safety: UL certification ensures that the circuit board meets rigorous safety standards and is safe for use in its intended application.

- Compliance: Many jurisdictions require UL certification for certain types of products, such as medical devices and industrial control panels. Obtaining UL certification can help manufacturers meet these requirements and avoid regulatory issues.

- Market Access: UL certification can help manufacturers access new markets and customers who require or prefer UL-certified products.

- Brand Reputation: Obtaining UL certification can enhance a manufacturer’s brand reputation and demonstrate their commitment to safety and quality.

Common Misconceptions About UL Certification

There are several common misconceptions about UL certification that manufacturers should be aware of:

- UL certification is not a guarantee of product quality or performance. It only ensures that the product meets UL’s safety standards.

- UL certification is not required for all products. It is voluntary in most cases, although some jurisdictions may require it for certain types of products.

- UL certification does not replace the need for proper installation, use, and maintenance of the product. Manufacturers must still provide clear instructions and warnings to ensure safe and proper use of the product.

Conclusion

UL certification is an important safety standard for electrical and electronic products, including circuit boards. Obtaining UL certification can provide several benefits for manufacturers and consumers, including improved safety, compliance with regulatory requirements, enhanced market access, and improved brand reputation.

Marking UL certification on circuit boards involves meeting specific requirements for the UL mark and choosing an appropriate marking method and placement. Manufacturers should carefully consider the costs and benefits of UL certification before pursuing it for their products.

By understanding the importance of UL certification and how to properly mark it on circuit boards, manufacturers can demonstrate their commitment to safety and quality, and provide consumers with greater confidence in their products.

Frequently Asked Questions (FAQ)

- What is the difference between UL Listed and UL Recognized?

-

UL Listed indicates that a product has been tested and meets UL’s safety standards for its intended use, while UL Recognized indicates that a component or material has been tested and meets UL’s safety standards for use in a specific product or application.

-

How long does the UL certification process take?

-

The length of the UL certification process can vary depending on the complexity of the product and the type of certification required. It can take anywhere from a few weeks to several months to complete the process.

-

Can I use the UL mark on my product without obtaining certification?

-

No, using the UL mark without obtaining certification is illegal and can result in legal action by UL.

-

What happens if my product fails UL testing?

-

If a product fails UL testing, the manufacturer will need to make necessary changes to the product design or manufacturing process to address the issues identified during testing. The product will then need to be retested to ensure compliance with UL standards.

-

How often do I need to renew my UL certification?

- UL certification is valid for a specific period of time, typically 1-5 years depending on the product and type of certification. Manufacturers must renew their certification before it expires to maintain compliance with UL standards.

No responses yet