Understanding the Rheostat: A Variable Resistor

A rheostat is an electrical component that functions as a variable resistor, allowing for the precise adjustment of resistance within an electrical circuit. Its primary purpose is to control the flow of current by varying the resistance, which in turn affects the voltage and power dissipation in the circuit. Rheostats are commonly used in applications where fine-tuning of electrical parameters is necessary, such as in dimming lights, controlling the speed of motors, or adjusting the volume in audio systems.

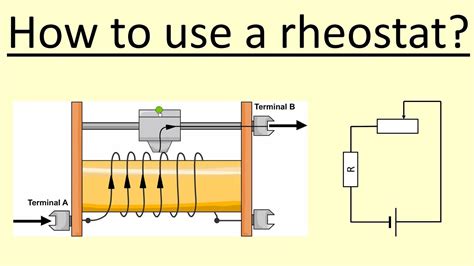

How a Rheostat Works

The working principle of a rheostat is based on the concept of resistance. A rheostat consists of a resistive element, typically a coiled wire or a conductive material, and a sliding contact or wiper. The resistive element has a fixed resistance value, and the position of the sliding contact determines the effective resistance of the rheostat.

As the sliding contact moves along the resistive element, it changes the length of the conductive path, thereby varying the resistance. The resistance is directly proportional to the length of the resistive element that the current must pass through. By adjusting the position of the sliding contact, the resistance can be increased or decreased, allowing for precise control over the current flow in the circuit.

Construction of a Rheostat

Rheostats are constructed using various materials and designs to suit different applications and power ratings. The most common types of rheostats include:

-

Wire-wound Rheostats:

These rheostats consist of a resistive wire wound around an insulating core, usually made of ceramic or fiberglass. The wire is often made of materials with high resistivity, such as nichrome or constantan. The sliding contact moves along the turns of the wire, varying the resistance. Wire-wound rheostats are suitable for high-power applications due to their ability to dissipate heat effectively. -

Carbon Rheostats:

Carbon rheostats use a resistive element made of carbon composition or carbon film. The sliding contact moves along the carbon track, changing the resistance. Carbon rheostats are commonly used in low-power applications and are less expensive compared to wire-wound rheostats. However, they have lower power ratings and are less precise in terms of resistance adjustment. -

Ceramic Rheostats:

Ceramic rheostats employ a resistive element made of a ceramic material with a conductive coating. The sliding contact moves along the ceramic surface, varying the resistance. Ceramic rheostats offer good heat dissipation and are suitable for high-temperature applications.

Rheostat Specifications

When selecting a rheostat for a specific application, several key specifications need to be considered:

-

Resistance Range:

Rheostats are available in various resistance ranges, typically from a few ohms to several thousand ohms. The resistance range should be chosen based on the requirements of the circuit and the desired level of control. -

Power Rating:

The power rating of a rheostat determines the maximum amount of power it can dissipate without overheating or failing. It is essential to select a rheostat with a power rating suitable for the intended application to ensure reliable operation and prevent damage to the component. -

Linearity:

Linearity refers to the relationship between the change in resistance and the position of the sliding contact. An ideal rheostat would have a linear relationship, meaning that the resistance changes proportionally with the movement of the sliding contact. However, in practice, rheostats may exhibit some non-linearity, which should be considered when precise control is required. -

Resolution:

The resolution of a rheostat indicates the smallest increment of resistance change that can be achieved by adjusting the sliding contact. Higher resolution allows for finer control over the resistance and more precise adjustments. -

Mechanical Durability:

Rheostats are subject to mechanical wear and tear due to the movement of the sliding contact. The durability of a rheostat depends on factors such as the quality of materials used, the smoothness of the resistive element, and the design of the sliding contact. Rheostats with robust construction and smooth operation are preferred for long-term reliability.

Applications of Rheostats

Rheostats find applications in various fields where precise control over electrical parameters is required. Some common applications include:

-

Lighting Control:

Rheostats are used in dimming circuits to adjust the brightness of lights. By varying the resistance, the current flow to the light source can be controlled, allowing for smooth dimming and customizable lighting levels. -

Motor Speed Control:

In DC motor applications, rheostats are employed to control the speed of the motor. By adjusting the resistance in series with the motor, the voltage supplied to the motor can be varied, resulting in changes in the motor’s speed. This is particularly useful in applications such as fan speed control or conveyor belt speed regulation. -

Audio Systems:

Rheostats are used as volume controls in audio systems. By varying the resistance, the signal level can be attenuated or amplified, allowing users to adjust the volume according to their preferences. -

Temperature Control:

In temperature control systems, rheostats are used as variable resistors to adjust the current flow to heating elements. By controlling the resistance, the temperature can be precisely regulated, making rheostats suitable for applications such as soldering irons, electric stoves, or industrial heating processes. -

Instrumentation:

Rheostats are used in various measuring instruments and Sensor Circuits to calibrate and adjust the sensitivity or range of the instrument. By varying the resistance, the output signal can be fine-tuned to match the desired measurement range or to compensate for variations in sensor characteristics. -

Voltage Dividers:

Rheostats can be used as variable voltage dividers in circuits where a specific voltage level needs to be obtained from a higher voltage source. By adjusting the resistance, the output voltage can be varied, making rheostats useful in applications such as reference voltage generation or signal conditioning.

Differences Between Rheostats and Potentiometers

While rheostats and potentiometers are both variable resistors, they have some key differences in terms of construction, functionality, and applications.

Construction

- Rheostats:

- Consist of a resistive element and a sliding contact or wiper.

- The sliding contact moves along the resistive element, changing the effective resistance.

-

Typically have two terminals: one connected to one end of the resistive element and the other connected to the sliding contact.

-

Potentiometers:

- Consist of a resistive element and a sliding contact or wiper.

- The sliding contact moves along the resistive element, dividing it into two sections.

- Have three terminals: two fixed terminals connected to both ends of the resistive element and a third terminal connected to the sliding contact.

Functionality

- Rheostats:

- Used to control the current flow in a circuit by varying the resistance.

- The sliding contact determines the effective resistance between the two terminals.

-

Typically used in series with the load to control the current.

-

Potentiometers:

- Used as voltage dividers to provide a variable voltage output.

- The sliding contact divides the resistive element into two sections, creating a voltage divider.

- The output voltage is taken from the sliding contact terminal and varies based on its position.

Applications

- Rheostats:

- Commonly used for current control applications, such as dimming lights or controlling motor speed.

- Suitable for high-power applications due to their ability to dissipate heat.

-

Often used in series with the load to control the current flow.

-

Potentiometers:

- Widely used for voltage control applications, such as volume controls in audio systems or position sensing in sensors.

- Suitable for low-power applications and precision voltage adjustment.

- Often used as voltage dividers to provide a variable voltage output.

Frequently Asked Questions (FAQ)

- What is the main function of a rheostat?

-

The main function of a rheostat is to control the current flow in an electrical circuit by varying the resistance. By adjusting the position of the sliding contact along the resistive element, the effective resistance can be changed, allowing for precise control over the current.

-

Can a rheostat be used as a potentiometer?

-

While a rheostat and a potentiometer are both variable resistors, they have different construction and functionality. A rheostat typically has two terminals and is used to control current, while a potentiometer has three terminals and is used as a voltage divider. In some cases, a rheostat can be used as a potentiometer by utilizing only two of its terminals, but it may not provide the same level of precision and functionality as a dedicated potentiometer.

-

What are the common materials used in the construction of rheostats?

-

Rheostats can be constructed using various materials depending on the specific requirements of the application. Common materials include:

- Wire-wound rheostats: Resistive wire (e.g., nichrome or constantan) wound around an insulating core.

- Carbon rheostats: Carbon composition or carbon film as the resistive element.

- Ceramic rheostats: Ceramic material with a conductive coating as the resistive element.

-

How do I select the appropriate power rating for a rheostat?

-

When selecting a rheostat, it is important to consider the power rating, which determines the maximum amount of power the rheostat can dissipate without overheating or failing. The power rating should be chosen based on the expected current flow and the maximum voltage applied across the rheostat. It is recommended to select a rheostat with a power rating higher than the anticipated power dissipation to ensure reliable operation and prevent damage to the component.

-

Are rheostats suitable for precision control applications?

- Rheostats can provide precise control over resistance and current flow, making them suitable for applications that require fine adjustments. However, the level of precision depends on factors such as the linearity of the rheostat, the resolution of the sliding contact, and the quality of the resistive element. High-quality rheostats with smooth operation and good linearity can offer precise control, while lower-quality rheostats may have limitations in terms of accuracy and repeatability. It is important to select a rheostat with specifications that meet the precision requirements of the specific application.

Conclusion

Rheostats are essential components in electrical circuits, providing a means to control current flow by varying resistance. Their ability to precisely adjust resistance makes them valuable in a wide range of applications, from lighting control and motor speed regulation to audio systems and instrumentation.

Understanding the working principle, construction, and specifications of rheostats is crucial for selecting the appropriate component for a given application. Factors such as resistance range, power rating, linearity, resolution, and mechanical durability should be considered to ensure optimal performance and reliability.

While rheostats and potentiometers share similarities as variable resistors, they differ in terms of construction, functionality, and typical applications. Rheostats are primarily used for current control, while potentiometers are commonly employed as voltage dividers.

By leveraging the versatility and precision of rheostats, designers and engineers can create electrical systems that offer fine-tuned control, improved efficiency, and enhanced user experiences. As technology continues to advance, the role of rheostats in shaping the future of electrical and electronic devices remains significant, enabling innovative solutions across various industries.

No responses yet