What is Wave Soldering?

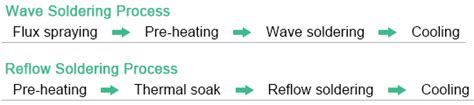

Wave soldering is a process that involves passing a PCB over a molten solder wave to create electrical connections between components and the board. The process begins by applying flux to the bottom side of the PCB to clean and prepare the surface for soldering. The board is then placed on a conveyor belt that moves it over a molten solder bath. As the board passes over the solder wave, the molten solder adheres to the exposed metal surfaces, creating a strong electrical and mechanical bond.

Advantages of Wave Soldering

- Cost-effective for large production runs: Wave soldering is ideal for high-volume production as it can process a large number of boards quickly and efficiently.

- Suitable for through-hole components: Wave soldering is the preferred method for soldering through-hole components, as the molten solder can easily flow through the holes and create a strong connection.

- Flexibility in board design: Wave soldering allows for more flexibility in board design, as components can be placed on both sides of the board.

Disadvantages of Wave Soldering

- Limited compatibility with surface mount components: Wave soldering is not well-suited for surface mount components, as the high temperature and turbulence of the solder wave can cause components to move or dislodge.

- Potential for thermal damage: The high temperature of the molten solder can cause thermal damage to heat-sensitive components.

- Difficulty in controlling solder joint quality: Controlling the quality of solder joints can be challenging in wave soldering, as factors such as solder wave height, conveyor speed, and flux type can affect the final result.

What is Reflow Soldering?

Reflow soldering is a process that involves applying solder paste to the PCB, placing components on the board, and then heating the entire assembly in a reflow oven to melt the solder and create a permanent connection. The solder paste contains a mixture of tiny solder particles and flux, which helps to clean and prepare the surfaces for soldering. The reflow oven heats the board in a controlled manner, following a specific temperature profile to ensure proper solder joint formation.

Advantages of Reflow Soldering

- Ideal for surface mount components: Reflow soldering is the preferred method for soldering surface mount components, as it allows for precise placement and strong solder joint formation.

- High precision and consistency: Reflow soldering offers high precision and consistency in solder joint quality, as the process is highly controlled and automated.

- Reduced thermal stress: Compared to wave soldering, reflow soldering subjects components to less thermal stress, as the entire board is heated evenly.

Disadvantages of Reflow Soldering

- Limited compatibility with through-hole components: Reflow soldering is not well-suited for through-hole components, as the solder paste may not flow properly into the holes.

- Higher setup costs: Reflow soldering requires specialized equipment such as stencils, solder paste dispensers, and reflow ovens, which can increase initial setup costs.

- Complexity in board design: Designing boards for reflow soldering can be more complex, as factors such as component placement, solder paste volume, and reflow profile must be carefully considered.

Comparison of Wave Soldering and Reflow Soldering

| Factor | Wave Soldering | Reflow Soldering |

|---|---|---|

| Suitable for through-hole components | Yes | Limited |

| Suitable for surface mount components | Limited | Yes |

| Production volume | High | Medium to high |

| Setup costs | Lower | Higher |

| Solder joint quality control | Challenging | High |

| Thermal stress on components | Higher | Lower |

| Board design flexibility | Higher | Lower |

Choosing Between Wave Soldering and Reflow Soldering

When deciding between wave soldering and reflow soldering for your PCB assembly, consider the following factors:

- Component types: If your board primarily uses through-hole components, wave soldering may be the better choice. For surface mount components, reflow soldering is generally preferred.

- Production volume: Wave soldering is more cost-effective for high-volume production, while reflow soldering is suitable for medium to high volumes.

- Board complexity: If your board design requires flexibility in component placement or has a mix of through-hole and surface mount components, wave soldering may be more appropriate. For boards with a high density of surface mount components, reflow soldering is often the better option.

- Quality requirements: Reflow soldering offers better control over solder joint quality and consistency, making it suitable for applications with strict quality requirements.

- Budget and setup costs: Wave soldering generally has lower setup costs compared to reflow soldering, which requires specialized equipment and tooling.

Frequently Asked Questions (FAQ)

-

Can wave soldering and reflow soldering be used together on the same board?

Yes, it is possible to use both wave soldering and reflow soldering on the same board in a process called mixed assembly. In this case, surface mount components are typically reflow soldered first, followed by wave soldering of through-hole components. -

Is it possible to reflow solder through-hole components?

While reflow soldering is not the preferred method for through-hole components, it is possible to use a technique called pin-in-paste, where solder paste is applied to the holes before placing the components. However, this method requires careful design considerations and may not be suitable for all applications. -

How does the size of the PCB affect the choice between wave soldering and reflow soldering?

The size of the PCB can influence the choice between wave soldering and reflow soldering. Wave soldering is generally more suitable for larger boards, as the solder wave can cover a greater area. Reflow soldering is often used for smaller boards with a high density of surface mount components. -

What are the environmental considerations when choosing between wave soldering and reflow soldering?

Both wave soldering and reflow soldering processes have environmental impacts, such as energy consumption and the use of lead-based solder alloys. However, many manufacturers are now using lead-free solder alloys and implementing eco-friendly practices to reduce their environmental footprint. -

Can reflow soldering be used for double-sided PCBs?

Yes, reflow soldering can be used for double-sided PCBs. In this case, the process is typically performed in two stages, with components on one side of the board being reflow soldered first, followed by the components on the other side. Special considerations, such as the use of adhesives or selective solder masks, may be necessary to prevent components from falling off during the second reflow cycle.

Conclusion

Choosing between wave soldering and reflow soldering for PCB assembly depends on various factors, including component types, production volume, board complexity, quality requirements, and budget. Wave soldering is generally more suitable for through-hole components and high-volume production, while reflow soldering is preferred for surface mount components and offers better control over solder joint quality.

Understanding the advantages and disadvantages of each method, as well as the specific requirements of your PCB design, will help you make an informed decision. In some cases, a combination of both wave soldering and reflow soldering may be necessary to achieve the best results.

As technology continues to advance, new soldering techniques and materials may emerge, offering even greater flexibility and efficiency in PCB assembly. Staying up-to-date with industry trends and best practices will ensure that you choose the most appropriate soldering method for your specific needs.

No responses yet