Introduction to Voltmeter ICs

A voltmeter is an essential tool for measuring electrical potential difference between two points in a circuit. Traditionally, analog voltmeters were used, which relied on the movement of a needle across a calibrated scale to indicate the voltage. However, with the advent of integrated circuit (IC) technology, digital voltmeters have become increasingly popular due to their accuracy, reliability, and ease of use.

Voltmeter ICs are specialized integrated circuits designed to measure voltage accurately. These ICs incorporate various features such as high input impedance, low drift, and wide voltage ranges, making them suitable for a variety of applications.

How Voltmeter ICs Work

Voltmeter ICs work by converting the analog voltage signal into a digital value that can be displayed on a screen or processed further. The core component of a voltmeter IC is an analog-to-digital converter (ADC), which performs this conversion.

The ADC in a voltmeter IC typically uses a technique called successive approximation to convert the analog voltage into a digital value. This process involves comparing the input voltage to a series of reference voltages generated by the ADC until the closest match is found. The digital value corresponding to this match is then output by the ADC.

Advantages of Voltmeter ICs

Voltmeter ICs offer several advantages over traditional analog voltmeters:

-

Accuracy: Voltmeter ICs can measure voltage with a high degree of accuracy, typically in the range of 0.1% to 0.5%. This is due to the precise nature of the ADC and the use of high-quality components within the IC.

-

Resolution: The resolution of a voltmeter IC refers to the smallest change in voltage that it can detect. Modern voltmeter ICs offer resolutions of up to 24 bits, allowing them to detect minute changes in voltage.

-

Reliability: Voltmeter ICs are highly reliable and can operate consistently over a wide range of temperatures and environmental conditions. They are also less prone to wear and tear compared to mechanical analog voltmeters.

-

Ease of use: Voltmeter ICs are easy to use and can be interfaced with various displays and processors. They often come with built-in features such as auto-ranging and data logging, which simplify the measurement process.

Types of Voltmeter ICs

There are several types of voltmeter ICs available, each with its own unique features and applications.

Digital Voltmeter ICs

Digital voltmeter ICs are the most common type of voltmeter IC. They provide a direct digital output of the measured voltage, which can be displayed on a screen or processed by a microcontroller.

Some popular digital voltmeter ICs include:

- Texas Instruments ADS1115

- Analog Devices AD7792

- Maxim Integrated MAX11200

These ICs offer high accuracy, resolution, and low power consumption, making them suitable for a wide range of applications.

Differential Voltmeter ICs

Differential voltmeter ICs are designed to measure the voltage difference between two points in a circuit. They are particularly useful in applications where the voltage being measured is referenced to a point other than ground.

Examples of differential voltmeter ICs include:

- Analog Devices AD629

- Texas Instruments INA128

- Linear Technology LT1167

These ICs offer high common-mode rejection and low noise, making them ideal for precision measurement applications.

Isolated Voltmeter ICs

Isolated voltmeter ICs provide electrical isolation between the measured voltage and the output circuitry. This is important in applications where the measured voltage may be at a significantly different potential than the rest of the system, or where there is a risk of electrical noise or interference.

Some examples of isolated voltmeter ICs are:

- Analog Devices AD7400

- Texas Instruments AMC1301

- Silicon Labs Si8920

These ICs use techniques such as optical isolation or capacitive coupling to provide high isolation voltages, typically in the range of several kilovolts.

Applications of Voltmeter ICs

Voltmeter ICs find applications in a wide range of industries and sectors. Some of the most common applications include:

Power Monitoring

Voltmeter ICs are used in power monitoring systems to measure the voltage levels in electrical power distribution networks. They help ensure that the voltage remains within acceptable limits and can detect any anomalies or faults in the system.

Battery Management Systems

In battery management systems, voltmeter ICs are used to monitor the voltage of individual cells or the overall battery pack. This information is used to determine the state of charge (SoC) of the battery and to prevent overcharging or undercharging, which can damage the battery.

Automotive Electronics

Voltmeter ICs are widely used in automotive electronics to monitor various electrical systems such as the battery, alternator, and sensors. They help ensure the reliable operation of these systems and can alert the driver in case of any issues.

Industrial Automation

In industrial automation systems, voltmeter ICs are used to monitor the voltage levels of various sensors and actuators. They help ensure that these components are operating within their specified ranges and can detect any faults or anomalies.

Medical Devices

Voltmeter ICs are used in medical devices such as patient monitors and diagnostic equipment to measure various physiological parameters such as ECG, EEG, and blood pressure. They provide accurate and reliable measurements that are critical for patient care and diagnosis.

Choosing the Right Voltmeter IC

When selecting a voltmeter IC for a particular application, several factors need to be considered:

-

Voltage Range: The voltmeter IC should be able to measure the expected range of voltages in the application. This includes both the minimum and maximum voltages that need to be measured.

-

Accuracy and Resolution: The required accuracy and resolution of the measurement should be determined based on the application requirements. Higher accuracy and resolution may be needed in certain critical applications.

-

Sampling Rate: The sampling rate of the voltmeter IC should be sufficient to capture any changes in the voltage being measured. This is particularly important in applications where the voltage may vary rapidly.

-

Interface: The interface of the voltmeter IC should be compatible with the rest of the system. Common interfaces include I2C, SPI, and UART.

-

Power Consumption: The power consumption of the voltmeter IC should be considered, especially in battery-powered applications where low power consumption is crucial.

-

Cost: The cost of the voltmeter IC should be balanced against the required features and performance. In some cases, a lower-cost IC may suffice, while in others, a more expensive IC with advanced features may be necessary.

Interfacing Voltmeter ICs

Interfacing voltmeter ICs with the rest of the system requires careful design and consideration of several factors.

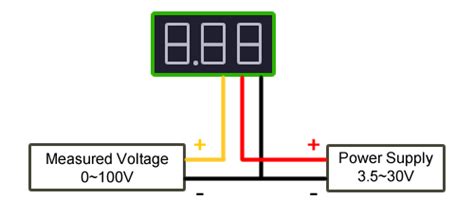

Power Supply

The voltmeter IC requires a stable and clean power supply to function accurately. The power supply should be decoupled using appropriate capacitors to minimize noise and ripple.

Input Scaling

The input voltage range of the voltmeter IC may differ from the actual voltage being measured. In such cases, input scaling using resistor dividers or operational amplifiers may be necessary to bring the voltage within the acceptable range of the IC.

Analog Front-End

The analog front-end circuitry before the voltmeter IC should be designed to minimize noise, interference, and loading effects. This may involve the use of filters, buffers, and shielding techniques.

Digital Interface

The digital interface of the voltmeter IC should be properly configured and connected to the rest of the system. This includes setting the appropriate communication protocol, data rate, and addressing scheme.

Calibration and Error Compensation

To ensure accurate voltage measurements, voltmeter ICs need to be calibrated and compensated for various errors.

Offset Error

Offset error refers to the non-zero output of the voltmeter IC when the input voltage is zero. This error can be compensated by measuring the offset voltage and subtracting it from the actual measurements.

Gain Error

Gain error refers to the deviation of the voltmeter IC’s scaling factor from its ideal value. This error can be compensated by measuring the gain factor and adjusting the measurements accordingly.

Temperature Drift

The performance of voltmeter ICs can vary with temperature, leading to drift in the measurements. This can be compensated by using temperature sensors and applying correction factors based on the measured temperature.

Periodic Calibration

Periodic calibration of the voltmeter IC is necessary to ensure that it remains accurate over time. This involves measuring known reference voltages and adjusting the IC’s parameters to match the expected values.

Conclusion

Voltmeter ICs are powerful and versatile tools for measuring voltage in various applications. They offer high accuracy, resolution, and reliability, making them an essential component in many electronic systems.

When selecting and using voltmeter ICs, careful consideration of the application requirements, interfacing, and calibration is necessary to ensure optimal performance and accuracy.

As technology continues to advance, we can expect to see even more sophisticated and feature-rich voltmeter ICs in the future, enabling new applications and possibilities in voltage measurement.

FAQs

- What is the difference between a voltmeter IC and a digital multimeter (DMM)?

A voltmeter IC is a specialized integrated circuit designed specifically for measuring voltage, while a digital multimeter is a more general-purpose instrument that can measure voltage, current, and resistance. Voltmeter ICs offer higher accuracy and resolution compared to most DMMs.

- Can voltmeter ICs measure AC voltage?

Yes, some voltmeter ICs are capable of measuring AC voltage by using techniques such as true RMS (root mean square) conversion. However, the specific capabilities depend on the particular IC being used.

- How do I interface a voltmeter IC with a microcontroller?

Most voltmeter ICs use standard communication protocols such as I2C or SPI to interface with microcontrollers. The specific interface depends on the IC being used and may require additional components such as pull-up resistors or level shifters.

- What is the maximum voltage that a voltmeter IC can measure?

The maximum voltage that a voltmeter IC can measure depends on its specifications and the input scaling circuitry used. Some ICs are designed for low-voltage applications and may have a maximum input range of a few volts, while others can measure voltages up to several hundred volts with appropriate scaling.

- How often should I calibrate my voltmeter IC?

The calibration frequency depends on the accuracy requirements of the application and the stability of the IC over time. In general, it is recommended to calibrate the IC at least once a year or whenever there is a significant change in the operating conditions, such as temperature or humidity. More frequent calibration may be necessary in critical applications where high accuracy is essential.

No responses yet