Introduction to PCB Visualization

PCB (Printed Circuit Board) visualization is a crucial aspect of the electronics design and manufacturing process. It enables designers, engineers, and stakeholders to visually represent and communicate the intricate details of a PCB design effectively. By leveraging PCB visualization techniques, businesses can streamline their workflows, enhance collaboration, and ensure the successful development and production of electronic devices.

In this comprehensive article, we will explore the importance of PCB visualization and how it can be integrated throughout the entire business process. From the initial concept and design stages to manufacturing and quality control, PCB visualization plays a vital role in driving efficiency, accuracy, and innovation.

The Benefits of PCB Visualization

Improved Communication and Collaboration

One of the primary benefits of PCB visualization is enhanced communication and collaboration among team members. By creating visual representations of PCB designs, designers and engineers can effectively convey complex ideas and concepts to stakeholders who may not have technical expertise. This visual language bridges the gap between technical and non-technical individuals, fostering better understanding and alignment within the organization.

PCB visualization tools allow teams to share and review designs in real-time, regardless of their physical location. This collaborative approach enables faster decision-making, reduces misunderstandings, and facilitates seamless integration of feedback and revisions.

Faster Design Iterations and Prototyping

PCB visualization accelerates the design iteration process by providing instant visual feedback. Designers can quickly experiment with different component placements, routing strategies, and layout optimizations, and immediately see the impact of their changes. This iterative approach allows for rapid prototyping and helps identify potential issues early in the design cycle.

By visualizing PCB designs in 3D, designers can gain a more comprehensive understanding of the spatial relationships between components, connectors, and mechanical enclosures. This enables them to optimize the board layout for manufacturability, thermal management, and signal integrity, reducing the likelihood of costly redesigns later in the process.

Enhanced Design Verification and Validation

PCB visualization plays a crucial role in design verification and validation. By generating high-quality visual representations of the PCB, designers can perform thorough design rule checks (DRC) and ensure compliance with manufacturing guidelines and industry standards. Visual inspection of the PCB Layout helps identify potential issues such as component clearance violations, insufficient trace spacing, or improper via placement.

Moreover, PCB visualization enables designers to conduct virtual prototyping and simulations. They can visualize the PCB’s behavior under different operating conditions, analyze signal integrity, and identify potential electromagnetic interference (EMI) issues. This virtual testing approach reduces the need for physical prototypes, saving time and resources while improving the overall design quality.

Streamlined Manufacturing and Assembly

PCB visualization extends beyond the design phase and plays a significant role in manufacturing and assembly processes. By providing clear and accurate visual instructions, PCB visualization helps streamline the production workflow and minimizes the risk of errors.

Visual aids such as assembly drawings, component placement diagrams, and solder paste stencil designs ensure that manufacturing personnel have the necessary information to assemble the PCB correctly. This reduces the chances of misinterpretation and improves the overall quality and reliability of the final product.

Additionally, PCB visualization enables better communication between design teams and manufacturing partners. By sharing visual representations of the PCB, designers can convey their intentions clearly, and manufacturers can provide valuable feedback on manufacturability and assembly considerations.

PCB Visualization Techniques and Tools

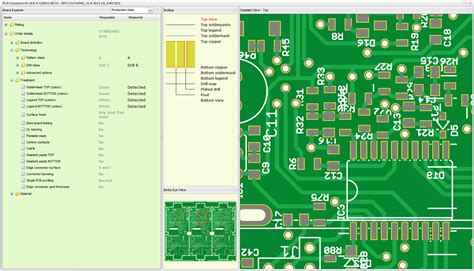

2D PCB Layout Visualization

2D PCB layout visualization is the foundation of PCB design. It involves creating a flat representation of the PCB, showing the component placement, trace routing, and various layers of the board. This visualization technique is essential for defining the physical layout of the PCB and ensuring proper connectivity between components.

Popular PCB design software packages, such as Altium Designer, Cadence OrCAD, and KiCad, offer powerful 2D layout visualization capabilities. These tools provide a wide range of features, including schematic capture, component libraries, design rule checking, and automatic routing algorithms.

3D PCB Visualization

3D PCB visualization takes the design process to the next level by providing a three-dimensional representation of the PCB. This technique allows designers to visualize the PCB from different angles, assess component heights, and ensure proper mechanical fitment within the enclosure.

3D PCB visualization tools, such as Altium Designer’s 3D View, Autodesk EAGLE’s 3D Viewer, and Solidworks PCB, enable designers to import 3D models of components and create realistic renderings of the PCB Assembly. This helps in identifying potential clearance issues, optimizing component placement for thermal management, and visualizing the overall product aesthetics.

Interactive PCB Visualization

Interactive PCB visualization enhances collaboration and communication by allowing stakeholders to explore and interact with the PCB design in real-time. This technique enables users to navigate through the PCB, select components, view their properties, and access relevant documentation.

Tools like EDA360 and Altium 365 provide cloud-based platforms for interactive PCB visualization. These platforms allow team members to access and review PCB designs from anywhere, provide feedback, and collaborate seamlessly. Interactive visualization also facilitates design reviews, making it easier to identify and address issues early in the development process.

Virtual and Augmented Reality for PCB Visualization

Virtual Reality (VR) and Augmented Reality (AR) technologies are revolutionizing PCB visualization by offering immersive and interactive experiences. VR allows designers to step inside a virtual representation of the PCB, enabling them to explore the design from various perspectives and identify potential issues.

AR, on the other hand, overlays digital information onto the real world, providing a blend of virtual and physical environments. AR-based PCB visualization can assist in assembly processes, guiding technicians through the placement of components and highlighting potential errors in real-time.

Best Practices for Effective PCB Visualization

Standardize Design Rules and Guidelines

To ensure consistent and effective PCB visualization, it is crucial to establish and follow standardized design rules and guidelines. These guidelines should cover aspects such as component placement, trace routing, via sizing, and manufacturing constraints.

By adhering to a set of well-defined design rules, designers can create PCBs that are visually coherent, manufacturable, and compliant with industry standards. This standardization also facilitates collaboration among team members and reduces the likelihood of errors and inconsistencies.

Use Clear and Consistent Naming Conventions

Implementing clear and consistent naming conventions for components, nets, and layers is essential for effective PCB visualization. Proper naming helps in identifying and referencing different elements of the PCB design quickly and accurately.

When naming components, it is recommended to use descriptive and concise names that reflect their functionality or purpose. Similarly, nets should be named based on their signal type or the components they connect. Layers should be labeled according to their purpose, such as “Top Layer,” “Bottom Layer,” or “Power Layer.”

Leverage Color Coding and Visual Hierarchy

Color coding and visual hierarchy are powerful tools in PCB visualization. By assigning distinct colors to different elements of the PCB, designers can enhance clarity and improve the readability of the design.

For example, different colors can be used to distinguish between component types, such as resistors, capacitors, and integrated circuits. Trace widths and colors can be varied based on their signal type or current carrying capacity. Visual hierarchy can be achieved by emphasizing critical components or connections, making them stand out from the rest of the design.

Regularly Review and Update Documentation

Comprehensive and up-to-date documentation is essential for effective PCB visualization. This includes schematic diagrams, component datasheets, assembly instructions, and design release notes.

Regular reviews and updates of the documentation ensure that all stakeholders have access to accurate and relevant information. Visual aids, such as 3D renderings and assembly drawings, should be included in the documentation to provide a clear understanding of the PCB design.

Collaborate with Manufacturing Partners

Collaborating closely with manufacturing partners is crucial for successful PCB visualization and production. Designers should engage with manufacturing experts early in the design process to gather feedback on manufacturability, assembly considerations, and potential optimizations.

By involving manufacturing partners in the visualization process, designers can ensure that the PCB design is optimized for production, reducing the risk of delays or quality issues. Regular communication and sharing of visual representations help in aligning expectations and facilitating a smooth transition from design to manufacturing.

Conclusion

PCB visualization is a vital aspect of the electronics design and manufacturing process. By leveraging advanced visualization techniques and tools, businesses can streamline their workflows, enhance collaboration, and ensure the successful development and production of electronic devices.

From improved communication and faster design iterations to enhanced design verification and streamlined manufacturing, PCB visualization offers numerous benefits throughout the entire business process. By adopting best practices such as standardized design rules, clear naming conventions, color coding, and regular documentation updates, organizations can maximize the effectiveness of their PCB visualization efforts.

As technology continues to evolve, the role of PCB visualization will only become more critical. Embracing innovative approaches like virtual and augmented reality will enable businesses to stay ahead of the curve and deliver cutting-edge electronic products to the market.

By prioritizing PCB visualization and integrating it throughout the business process, companies can drive efficiency, accuracy, and innovation, ultimately leading to successful outcomes and satisfied customers.

Frequently Asked Questions (FAQ)

-

What is PCB visualization, and why is it important?

PCB visualization refers to the process of creating visual representations of printed circuit board designs. It is important because it enhances communication, collaboration, and understanding among team members, stakeholders, and manufacturing partners. PCB visualization helps in identifying potential issues early, optimizing designs for manufacturability, and streamlining the overall development process. -

What are the different techniques used for PCB visualization?

The main techniques used for PCB visualization include: - 2D PCB layout visualization: Creating a flat representation of the PCB, showing component placement, trace routing, and layers.

- 3D PCB visualization: Providing a three-dimensional representation of the PCB, allowing designers to assess component heights and mechanical fitment.

- Interactive PCB visualization: Enabling stakeholders to explore and interact with the PCB design in real-time, facilitating collaboration and design reviews.

-

Virtual and Augmented Reality: Offering immersive and interactive experiences for PCB visualization, assisting in design exploration and assembly processes.

-

How can PCB visualization improve collaboration among team members?

PCB visualization enhances collaboration by providing a visual language that bridges the gap between technical and non-technical individuals. It allows team members to share and review designs in real-time, regardless of their physical location. Visual representations of the PCB facilitate faster decision-making, reduce misunderstandings, and enable seamless integration of feedback and revisions. -

What are the benefits of 3D PCB visualization?

3D PCB visualization offers several benefits, including: - Providing a comprehensive understanding of the spatial relationships between components, connectors, and mechanical enclosures.

- Enabling designers to optimize the board layout for manufacturability, thermal management, and signal integrity.

- Allowing designers to identify potential clearance issues and visualize the overall product aesthetics.

-

Facilitating virtual prototyping and simulations to analyze PCB behavior under different operating conditions.

-

How can businesses ensure effective PCB visualization throughout the development process?

To ensure effective PCB visualization, businesses can follow these best practices: - Establish and adhere to standardized design rules and guidelines for consistency and manufacturability.

- Implement clear and consistent naming conventions for components, nets, and layers to enhance clarity and readability.

- Leverage color coding and visual hierarchy to distinguish different elements of the PCB and emphasize critical components or connections.

- Regularly review and update documentation, including visual aids, to provide accurate and relevant information to all stakeholders.

- Collaborate closely with manufacturing partners to gather feedback, optimize designs for production, and ensure a smooth transition from design to manufacturing.

| Technique | Benefits |

|---|---|

| 2D PCB Layout Visualization | – Foundation of PCB design – Defines physical layout and connectivity – Supported by popular PCB design software |

| 3D PCB Visualization | – Provides 3D representation of PCB – Assesses component heights and mechanical fitment – Identifies clearance issues and optimizes layout |

| Interactive PCB Visualization | – Enhances collaboration and communication – Allows real-time exploration and interaction – Facilitates design reviews and issue identification |

| VR/AR PCB Visualization | – Offers immersive and interactive experiences – Assists in design exploration and assembly processes – Blends virtual and physical environments |

By leveraging these PCB visualization techniques and following best practices, businesses can streamline their development process, improve collaboration, and deliver high-quality electronic products to the market efficiently.

No responses yet