Introduction to IPC 2221 Calculator

The IPC 2221 Calculator is a powerful tool for designers and engineers working on high voltage projects. This calculator is based on the IPC 2221 standard, which provides guidelines for the design of printed circuit boards (PCBs) for electronic equipment. The IPC 2221 standard covers various aspects of PCB design, including conductor width, spacing, and thickness, as well as electrical characteristics such as voltage, current, and resistance.

What is the IPC 2221 Standard?

The IPC 2221 standard, titled “Generic Standard on Printed Board Design,” is a comprehensive document that provides guidelines for the design of PCBs. It was developed by the IPC (Association Connecting Electronics Industries), a global trade association for the electronics industry. The standard aims to ensure the reliability, manufacturability, and performance of PCBs by providing best practices and recommendations for various aspects of PCB design.

Why Use an IPC 2221 Calculator for High Voltage Design?

High voltage design requires careful consideration of various factors to ensure the safety, reliability, and performance of the electronic equipment. The IPC 2221 Calculator is an invaluable tool for designers working on high voltage projects, as it helps them determine the appropriate conductor width, spacing, and thickness for their specific application.

By using an IPC 2221 Calculator, designers can:

- Ensure compliance with the IPC 2221 standard

- Optimize the design for manufacturability and reliability

- Minimize the risk of electrical failures, such as short circuits or arcing

- Reduce the need for costly prototypes and iterations

Key Factors in High Voltage PCB Design

When designing PCBs for high voltage applications, several key factors must be considered to ensure the safety and reliability of the electronic equipment. These factors include:

Voltage and Current Ratings

The voltage and current ratings of the PCB must be appropriate for the intended application. The IPC 2221 Calculator helps designers determine the minimum conductor width and spacing required to handle the specified voltage and current levels safely.

Creepage and Clearance Distances

Creepage is the shortest path between two conductors along the surface of an insulating material, while clearance is the shortest distance between two conductors through air. In high voltage design, maintaining adequate creepage and clearance distances is crucial to prevent electrical breakdown and arcing. The IPC 2221 Calculator provides recommendations for minimum creepage and clearance distances based on the voltage level and the pollution degree of the environment.

Insulation Materials

The choice of insulation materials is critical in high voltage PCB design. The insulation must have a high dielectric strength to withstand the applied voltage without breaking down. Common insulation materials for high voltage applications include FR-4, polyimide, and ceramic. The IPC 2221 Calculator takes into account the properties of the insulation material when determining the minimum conductor spacing and thickness.

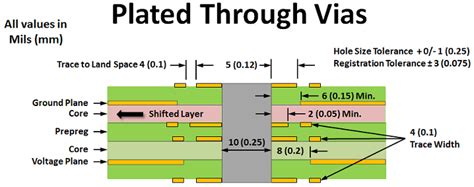

Conductor Thickness and Width

The thickness and width of the conductors on the PCB must be sufficient to handle the expected current flow without overheating or causing voltage drops. The IPC 2221 Calculator provides recommendations for minimum conductor thickness and width based on the current rating and the temperature rise of the conductors.

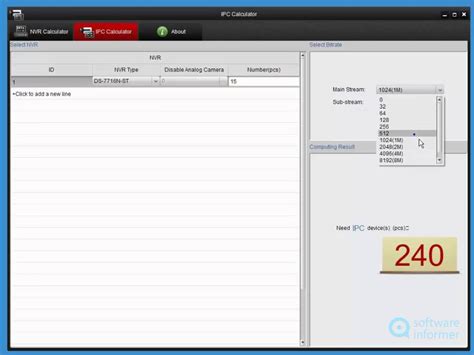

Using the IPC 2221 Calculator

To use the IPC 2221 Calculator for high voltage design, follow these steps:

- Determine the voltage and current ratings of your application.

- Select the appropriate insulation material based on the dielectric strength and other properties.

- Input the voltage, current, and insulation material information into the IPC 2221 Calculator.

- Specify the pollution degree of the environment (1-4) based on the IPC 2221 standard.

- Review the calculator’s recommendations for minimum conductor width, spacing, and thickness.

- Adjust your PCB design according to the calculator’s recommendations.

- Verify that your design meets all other requirements of the IPC 2221 standard and any additional industry or application-specific standards.

Example: Designing a 1000V PCB

Let’s walk through an example of using the IPC 2221 Calculator to design a PCB for a 1000V application.

- Voltage rating: 1000V

- Current rating: 5A

- Insulation material: FR-4 (dielectric strength: 20 kV/mm)

- Pollution degree: 2 (office or lab environment)

Inputting this information into the IPC 2221 Calculator, we get the following recommendations:

| Parameter | Recommendation |

|---|---|

| Minimum conductor width | 0.5 mm |

| Minimum conductor spacing | 1.5 mm |

| Minimum conductor thickness | 35 μm |

Based on these recommendations, we can design our PCB with conductors that are at least 0.5 mm wide, spaced at least 1.5 mm apart, and have a minimum thickness of 35 μm. This design should ensure the safety and reliability of our 1000V application.

Advanced Topics in High Voltage PCB Design

In addition to the basic guidelines provided by the IPC 2221 Calculator, there are several advanced topics that designers should consider when working on high voltage PCB projects.

Partial Discharge and Corona Effects

Partial discharge (PD) and corona effects are common issues in high voltage systems. PD occurs when there is a localized dielectric breakdown in an insulation material, while corona is a discharge that occurs in a gaseous medium when the electric field strength exceeds a certain threshold. Both PD and corona can cause insulation degradation, leading to premature failure of the electronic equipment.

To minimize PD and corona effects, designers can:

- Use insulation materials with high resistance to PD and corona

- Increase the creepage and clearance distances between conductors

- Avoid sharp edges and points on conductors, which can concentrate the electric field

- Use conformal coatings or potting compounds to protect the PCB from environmental factors

High Voltage Connectors and Cabling

Selecting the appropriate connectors and cabling is crucial for high voltage applications. The connectors and cables must be rated for the expected voltage and current levels, and they must maintain adequate insulation and shielding to prevent electrical interference and breakdown.

Some common types of high voltage connectors include:

- Circular plastic connectors (CPC)

- High voltage D-sub connectors

- Modular high voltage connectors

- Custom-designed connectors for specific applications

When choosing high voltage cables, designers should consider factors such as:

- Voltage and current ratings

- Insulation material and thickness

- Shielding effectiveness

- Flexibility and durability

- Environmental resistance (e.g., temperature, humidity, chemicals)

Testing and Certification

High voltage PCBs must undergo rigorous testing and certification to ensure their safety and reliability. Some common tests for high voltage PCBs include:

- Dielectric withstand voltage (DWV) test

- Insulation resistance (IR) test

- Partial discharge (PD) test

- Leakage current test

- Visual and X-ray inspections

In addition to these tests, high voltage PCBs may need to comply with various industry standards and certifications, such as:

- UL (Underwriters Laboratories)

- IEC (International Electrotechnical Commission)

- CSA (Canadian Standards Association)

- VDE (Verband Deutscher Elektrotechniker)

Designers should consult the relevant standards and certifications for their specific application to ensure compliance and safety.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between creepage and clearance in high voltage PCB design?

A: Creepage is the shortest path between two conductors along the surface of an insulating material, while clearance is the shortest distance between two conductors through air. Both creepage and clearance distances are important in high voltage design to prevent electrical breakdown and arcing. -

Q: How does the pollution degree affect the minimum spacing requirements in the IPC 2221 Calculator?

A: The pollution degree is a measure of the environmental contamination that can affect the insulation properties of the PCB. A higher pollution degree requires greater creepage and clearance distances to maintain the same level of insulation safety. The IPC 2221 Calculator adjusts the minimum spacing recommendations based on the specified pollution degree. -

Q: Can I use the IPC 2221 Calculator for DC and AC voltage applications?

A: Yes, the IPC 2221 Calculator can be used for both DC and AC voltage applications. However, keep in mind that AC voltages may require additional considerations, such as the frequency and waveform, which can affect the insulation requirements. -

Q: What should I do if my high voltage PCB design requires smaller spacings than those recommended by the IPC 2221 Calculator?

A: If your design requires smaller spacings than those recommended by the IPC 2221 Calculator, you should carefully evaluate the risks and consider alternative design options. These may include using higher-grade insulation materials, conformal coatings, or potting compounds to enhance the insulation properties. Consultation with experienced high voltage PCB designers or the IPC organization can also provide guidance in these situations. -

Q: Are there any additional resources or tools available for high voltage PCB design beyond the IPC 2221 Calculator?

A: Yes, there are several additional resources and tools available for high voltage PCB design. These include simulation software for electric field analysis, such as ANSYS or COMSOL, which can help optimize the PCB layout and identify potential weak points in the insulation. Additionally, there are specialized high voltage design forums and communities where designers can share knowledge and seek advice from experienced professionals.

Conclusion

The IPC 2221 Calculator is a valuable tool for designers working on high voltage PCB projects. By providing recommendations for minimum conductor width, spacing, and thickness based on the voltage, current, and insulation material properties, the calculator helps ensure the safety, reliability, and performance of high voltage electronic equipment.

However, designers should also consider advanced topics such as partial discharge, corona effects, high voltage connectors and cabling, and testing and certification requirements when working on high voltage PCB projects. By combining the guidelines provided by the IPC 2221 Calculator with a thorough understanding of these advanced topics, designers can create high-quality, safe, and reliable high voltage PCBs for a wide range of applications.

No responses yet