Introduction to USB PCB

USB (Universal Serial Bus) has become the standard interface for connecting various peripherals and devices to computers and other electronic systems. At the heart of any USB device lies the USB PCB (Printed Circuit Board), which plays a crucial role in facilitating communication and power transfer between the device and the host system. This article will delve into the intricacies of USB PCBs, exploring their components, design considerations, and the role they play in enabling seamless USB connectivity.

Understanding the USB Protocol

To grasp the significance of USB PCBs, it is essential to understand the USB protocol itself. USB is a serial communication protocol that allows devices to communicate with a host system using a standardized set of rules and specifications. The USB protocol defines the following key aspects:

| Aspect | Description |

|---|---|

| Data Transfer | USB supports various data transfer types, including bulk, interrupt, isochronous, and control transfers. |

| Power Delivery | USB provides power to connected devices, with different voltage levels and current capabilities depending on the USB version. |

| Device Classes | USB defines device classes, such as HID (Human Interface Device), MSC (Mass Storage Class), and CDC (Communications Device Class), which specify the functionality and behavior of devices. |

USB Versions and Speeds

Over the years, USB has evolved through different versions, each offering increased bandwidth and enhanced features. The following table summarizes the main USB versions and their respective speeds:

| USB Version | Maximum Speed |

|---|---|

| USB 1.1 | 12 Mbps |

| USB 2.0 | 480 Mbps |

| USB 3.0 | 5 Gbps |

| USB 3.1 | 10 Gbps |

| USB 3.2 | 20 Gbps |

| USB 4.0 | 40 Gbps |

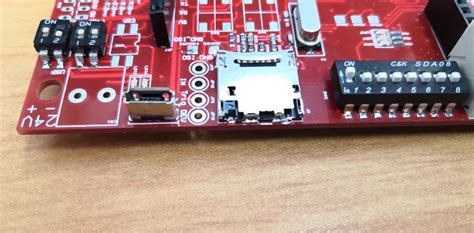

Anatomy of a USB PCB

A USB PCB is a complex assembly of various components that work together to enable USB functionality. Let’s explore the key components found on a typical USB PCB.

USB Connector

The USB connector is the physical interface between the USB device and the host system. It consists of a set of pins or contacts that carry power, ground, and data signals. The most common USB connector types are:

- USB Type-A: Commonly found on host systems and USB hubs.

- USB Type-B: Used on peripheral devices such as printers and external hard drives.

- USB Type-C: A reversible connector that supports higher speeds and power delivery.

USB Controller

The USB controller is the brain of the USB PCB. It manages the USB communication protocol, handles data transfer, and controls the overall operation of the USB device. The USB controller typically integrates the following functionalities:

- USB transceiver: Responsible for sending and receiving USB signals.

- Serial Interface Engine (SIE): Implements the USB protocol and manages data packets.

- Microcontroller: Executes firmware to control the USB device’s behavior.

Voltage Regulator

USB PCBs often include a voltage regulator to convert the incoming USB voltage (5V) to the appropriate voltage levels required by the device’s components. The voltage regulator ensures a stable and regulated power supply for the USB controller and other circuitry on the PCB.

Crystal Oscillator

A crystal oscillator is used to generate a precise clock signal for the USB controller. The clock signal synchronizes the USB communication and ensures accurate timing for data transfer. The most common crystal frequencies used in USB PCBs are 12 MHz and 24 MHz.

ESD protection

Electrostatic Discharge (ESD) protection is crucial in USB PCBs to safeguard the sensitive electronic components from voltage spikes and static electricity. ESD protection components, such as transient voltage suppressors (TVS) and ESD diodes, are placed near the USB connector to absorb and divert any harmful voltage surges.

Designing a USB PCB

Designing a USB PCB requires careful consideration of various factors to ensure optimal performance, reliability, and adherence to USB standards. Some key design considerations include:

Signal Integrity

Maintaining signal integrity is crucial for reliable USB communication. USB PCBs should be designed with proper impedance matching, controlled impedance traces, and appropriate termination to minimize signal reflections and ensure data integrity.

Power Management

USB PCBs must manage power effectively to meet the power requirements of the connected devices. This involves selecting the appropriate voltage regulators, current limiting resistors, and power filtering components to provide clean and stable power to the USB controller and other circuitry.

EMI/EMC Compliance

USB devices must comply with electromagnetic interference (EMI) and electromagnetic compatibility (EMC) regulations to avoid interfering with other electronic devices and to ensure immunity against external electromagnetic disturbances. USB PCBs should incorporate EMI/EMC mitigation techniques such as proper grounding, shielding, and filtering.

Layout Considerations

The layout of a USB PCB plays a significant role in its performance and reliability. Some key layout considerations include:

- Proper component placement to minimize signal path lengths and crosstalk.

- Adequate ground planes and power planes for low-impedance current return paths.

- Proper routing of high-speed signals and differential pairs.

- Separation of analog and digital sections to minimize noise coupling.

USB PCB testing and Certification

To ensure that a USB PCB meets the required specifications and standards, thorough testing and certification processes are necessary. Some common tests performed on USB PCBs include:

Functional Testing

Functional testing verifies that the USB device operates as intended, including data transfer, enumeration, and power management. This involves testing the USB PCB with various host systems and testing tools to ensure compatibility and reliability.

Compliance Testing

USB devices must undergo compliance testing to ensure adherence to USB specifications and standards. Compliance testing covers various aspects such as electrical characteristics, protocol implementation, and interoperability. USB-IF (USB Implementers Forum) provides certification programs to validate USB compliance.

Environmental Testing

USB PCBs may be subjected to environmental testing to assess their performance and reliability under different operating conditions. This includes temperature cycling, humidity testing, vibration testing, and shock testing to ensure the PCB can withstand the intended operating environment.

FAQs

What is the difference between a USB hub and a USB controller?

A USB hub is an external device that allows multiple USB devices to be connected to a single USB port on the host system. It essentially expands the number of available USB ports. On the other hand, a USB controller is an integrated circuit on the USB PCB that manages the USB communication protocol and controls the overall operation of the USB device.

Can a USB PCB be designed to support multiple USB versions?

Yes, a USB PCB can be designed to support multiple USB versions. However, it requires careful design considerations to ensure compatibility and proper implementation of the different USB protocols. The USB controller and other components must be selected to support the desired USB versions, and the PCB layout must accommodate the specific requirements of each version.

What are the common challenges in USB PCB design?

Some common challenges in USB PCB design include maintaining signal integrity, managing power efficiently, ensuring EMI/EMC compliance, and achieving proper impedance matching. Additionally, the high-speed nature of USB communication requires careful layout considerations to minimize signal reflections, crosstalk, and other signal integrity issues.

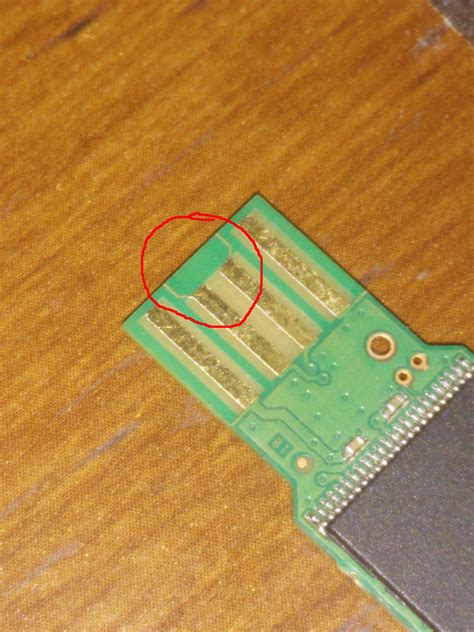

How important is the quality of the USB connector in a USB PCB?

The quality of the USB connector is extremely important in a USB PCB. A poor-quality connector can lead to unreliable connections, signal degradation, and even physical damage to the PCB or the connected devices. It is crucial to select high-quality USB connectors from reputable manufacturers and ensure proper mounting and soldering techniques during PCB assembly.

Can a faulty USB PCB damage the connected devices or the host system?

Yes, a faulty USB PCB can potentially damage the connected devices or the host system. Issues such as short circuits, overcurrent conditions, or ESD events can cause damage to the USB components or even propagate to the connected devices. Proper design, testing, and protection mechanisms, such as current limiting and ESD protection, are essential to mitigate the risk of damage.

Conclusion

USB PCBs form the backbone of any USB device, enabling seamless communication and power transfer between the device and the host system. Understanding the components, design considerations, and testing requirements of USB PCBs is crucial for developing reliable and high-performance USB devices.

From the USB connector and controller to voltage regulators and ESD protection, each component plays a vital role in the overall functionality of the USB PCB. Careful design choices, such as maintaining signal integrity, managing power effectively, and ensuring EMI/EMC compliance, are essential for optimal USB performance.

As USB technology continues to evolve, with higher speeds and enhanced features, USB PCB design will also need to adapt and innovate to keep pace with the advancing standards. By staying informed about the latest USB specifications, design techniques, and testing methodologies, engineers and designers can create robust and future-proof USB PCBs that meet the evolving needs of the electronics industry.

No responses yet