Introduction to EMC Troubleshooting

Electromagnetic Compatibility (EMC) is a critical aspect of electronic product design and development. EMC ensures that electronic devices can operate reliably in their intended electromagnetic environment without causing or being susceptible to electromagnetic interference (EMI). Troubleshooting EMC immunity issues is an essential skill for engineers working on electronic products, as it helps identify and resolve problems related to EMI susceptibility.

In this article, we will discuss various aspects of EMC troubleshooting, focusing on immunity issues. We will cover the fundamentals of EMC, common EMC immunity problems, diagnostic techniques, and practical solutions to mitigate EMI susceptibility.

Understanding EMC Immunity

What is EMC Immunity?

EMC immunity refers to an electronic device’s ability to operate as intended in the presence of electromagnetic disturbances. These disturbances can come from various sources, such as:

- Radio frequency (RF) emissions from nearby electronic devices

- Electrostatic discharge (ESD) events

- Transient electrical disturbances on power and signal lines

- Magnetic fields from power transformers or motors

EMC Immunity Standards

Several international standards define the requirements for EMC immunity testing and compliance. Some of the most common standards include:

- IEC 61000-4 series: Electromagnetic compatibility (EMC) – Part 4: Testing and measurement techniques

- EN 55024: Information technology equipment – Immunity characteristics – Limits and methods of measurement

- MIL-STD-461: Requirements for the control of electromagnetic interference characteristics of subsystems and equipment

These standards specify the test methods, test levels, and performance criteria for evaluating the immunity of electronic devices to various electromagnetic disturbances.

Common EMC Immunity Problems

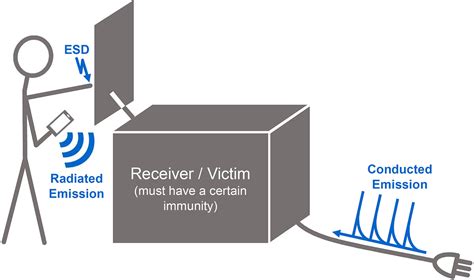

Radiated Immunity Issues

Radiated immunity problems occur when an electronic device is susceptible to RF electromagnetic fields. Common symptoms of radiated immunity issues include:

- Unexpected resets or shutdowns

- Erratic behavior or malfunctions

- Degraded performance or loss of functionality

Radiated immunity issues can be caused by factors such as:

- Insufficient shielding of the device enclosure

- Poor grounding or bonding of cables and connectors

- Inadequate filtering of I/O ports and power inputs

- Coupling of RF energy through apertures or seams in the enclosure

Conducted Immunity Issues

Conducted immunity problems arise when electromagnetic disturbances couple into an electronic device through its power or signal lines. Common symptoms of conducted immunity issues include:

- Power supply fluctuations or interruptions

- Communication errors or data corruption

- False triggering of sensors or actuators

Conducted immunity issues can be caused by factors such as:

- Insufficient filtering of power inputs and outputs

- Inadequate transient protection on signal lines

- Poor cable shielding or grounding

- Coupling of transient disturbances through shared power or ground planes

Electrostatic Discharge (ESD) Issues

ESD events can cause significant damage or disruption to electronic devices. Common symptoms of ESD susceptibility include:

- Permanent damage to components or circuit boards

- Temporary malfunctions or resets

- Latch-up or burnout of integrated circuits

ESD susceptibility can be caused by factors such as:

- Insufficient ESD protection on I/O ports and user interfaces

- Poor grounding or bonding of conductive surfaces

- Inadequate handling and assembly procedures for ESD-sensitive components

EMC Troubleshooting Techniques

Visual Inspection

Visual inspection is the first step in troubleshooting EMC immunity issues. This involves examining the device and its components for signs of physical damage, poor workmanship, or design flaws. Some key areas to inspect include:

- Enclosure integrity: Check for gaps, seams, or damage that could allow RF energy to enter or escape.

- Cable and connector

shielding: Ensure that cables are properly shielded and terminated, and that connectors are securely fastened and grounded. - Component placement: Look for potential sources of coupling or crosstalk, such as closely spaced high-speed traces or unshielded components.

Immunity Testing

Immunity testing is the most direct way to identify and characterize EMC immunity problems. This involves subjecting the device to controlled electromagnetic disturbances and monitoring its performance. Some common immunity tests include:

- Radiated RF immunity testing: Exposing the device to high-frequency electromagnetic fields and monitoring for malfunctions or degraded performance.

- Conducted RF immunity testing: Injecting RF disturbances into the device’s power and signal lines and monitoring for susceptibility.

- ESD testing: Applying controlled ESD events to the device’s user interfaces and external surfaces to check for damage or disruption.

Immunity testing can be performed in-house using specialized test equipment, or outsourced to accredited EMC testing laboratories.

Spectrum Analysis

Spectrum analysis is a useful technique for identifying the sources and characteristics of electromagnetic disturbances. A spectrum analyzer can be used to measure the frequency, amplitude, and bandwidth of RF emissions from the device or its environment. This information can help pinpoint the root causes of immunity problems and guide the selection of appropriate mitigation techniques.

Near-Field Probing

Near-field probing is a technique for locating the sources of electromagnetic emissions or susceptibilities on a device’s circuit board or components. A near-field probe is a small, hand-held antenna that can detect electric or magnetic fields in close proximity to the device. By scanning the probe over the device’s surface, engineers can identify “hot spots” where emissions or coupling are occurring, and take targeted measures to mitigate the problem.

Practical Solutions for EMC Immunity

Shielding

Shielding is a fundamental technique for improving EMC immunity. Shielding involves enclosing the device or its components in a conductive barrier that attenuates electromagnetic fields. Some common shielding techniques include:

- Metallic enclosures: Using metal cases, covers, or gaskets to create a continuous shield around the device.

- Shielded cables: Using cables with braided or foil shields to minimize coupling of external disturbances.

- Shielding materials: Applying conductive coatings, tapes, or paints to non-metallic surfaces to create a shielding effect.

Grounding and Bonding

Proper grounding and bonding are essential for controlling electromagnetic emissions and improving immunity. Grounding involves connecting conductive surfaces to a common reference point, such as the earth or a chassis ground. Bonding involves creating low-impedance electrical connections between conductive surfaces to minimize potential differences and reduce coupling. Some key grounding and bonding techniques include:

- Star grounding: Connecting all ground points to a single, central ground reference to minimize ground loops and common-mode noise.

- Shield termination: Properly terminating cable shields to the device enclosure or ground plane to minimize RF leakage.

- Bonding straps: Using short, wide, and flexible conductors to bond conductive surfaces together and reduce impedance.

Filtering

Filtering is a technique for attenuating unwanted frequency components from power and signal lines. Filters can be used to suppress electromagnetic emissions or to block external disturbances from entering the device. Some common types of filters include:

- Power line filters: LC or RC filters installed on the device’s power input to attenuate conducted RF disturbances.

- I/O filters: Ferrite beads, capacitors, or resistors installed on signal lines to suppress high-frequency noise or transients.

- EMI filters: Specialized filters designed to attenuate specific frequency bands, such as those used for wireless communications or power line harmonics.

Transient Protection

Transient protection is a technique for mitigating the effects of short-duration, high-energy disturbances, such as ESD or voltage spikes. Transient protection devices (TPDs) are designed to clamp or divert transient currents before they can damage or disrupt sensitive components. Some common types of TPDs include:

- Varistors: Voltage-dependent resistors that provide a low-impedance path for transient currents.

- TVS diodes: Transient voltage suppression diodes that clamp voltage spikes to a safe level.

- Gas discharge tubes: Devices that ionize at high voltages to provide a low-impedance path for transient currents.

Layout and Routing

Careful layout and routing of circuit boards can help minimize EMC immunity problems. Some key layout and routing techniques include:

- Minimizing loop areas: Keeping high-speed traces and power loops as small as possible to reduce radiated emissions and pickup.

- Separating sensitive circuits: Physically separating noise-sensitive circuits, such as analog or RF sections, from noisy digital or power circuits.

- Routing control: Using ground planes, guard traces, or shielded traces to control the flow of high-frequency currents and minimize crosstalk.

FAQs

Q1: What is the difference between EMC emissions and immunity?

A1: EMC emissions refer to the electromagnetic disturbances generated by an electronic device, which can interfere with the operation of other devices. EMC immunity, on the other hand, refers to a device’s ability to operate as intended in the presence of electromagnetic disturbances from other sources.

Q2: What are the most common sources of EMC immunity problems?

A2: Some of the most common sources of EMC immunity problems include:

– Radiated RF emissions from nearby electronic devices

– Conducted disturbances on power and signal lines

– Electrostatic discharge (ESD) events

– Transient electrical disturbances, such as voltage spikes or power surges

Q3: What are the key steps in troubleshooting EMC immunity issues?

A3: The key steps in troubleshooting EMC immunity issues are:

1. Visual inspection: Examining the device and its components for physical damage, poor workmanship, or design flaws.

2. Immunity testing: Subjecting the device to controlled electromagnetic disturbances and monitoring its performance.

3. Spectrum analysis: Measuring the frequency, amplitude, and bandwidth of RF emissions from the device or its environment.

4. Near-field probing: Locating the sources of electromagnetic emissions or susceptibilities on the device’s circuit board or components.

5. Implementing practical solutions: Applying techniques such as shielding, grounding, filtering, transient protection, and layout optimization to mitigate the problem.

Q4: What are some common shielding techniques for improving EMC immunity?

A4: Some common shielding techniques for improving EMC immunity include:

– Using metallic enclosures, such as metal cases, covers, or gaskets, to create a continuous shield around the device.

– Using shielded cables with braided or foil shields to minimize coupling of external disturbances.

– Applying conductive coatings, tapes, or paints to non-metallic surfaces to create a shielding effect.

Q5: How can layout and routing techniques help minimize EMC immunity problems?

A5: Careful layout and routing of circuit boards can help minimize EMC immunity problems by:

– Keeping high-speed traces and power loops as small as possible to reduce radiated emissions and pickup.

– Physically separating noise-sensitive circuits, such as analog or RF sections, from noisy digital or power circuits.

– Using ground planes, guard traces, or shielded traces to control the flow of high-frequency currents and minimize crosstalk.

Conclusion

Troubleshooting EMC immunity issues is a critical skill for engineers working on electronic products. By understanding the fundamentals of EMC, common immunity problems, and diagnostic techniques, engineers can identify and resolve issues related to electromagnetic susceptibility. Practical solutions such as shielding, grounding, filtering, transient protection, and layout optimization can help mitigate EMC immunity problems and ensure that electronic devices operate reliably in their intended electromagnetic environment.

As the complexity of electronic systems continues to increase, and the electromagnetic spectrum becomes more crowded, the importance of EMC troubleshooting will only continue to grow. By staying up-to-date with the latest standards, techniques, and best practices, engineers can effectively tackle EMC immunity challenges and develop products that are both reliable and compliant.

No responses yet