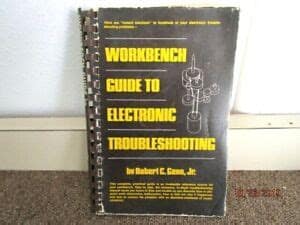

Introduction to EMC and Workbench Troubleshooting

Electromagnetic compatibility (EMC) is a critical aspect of electronic device design and functionality. It ensures that electronic devices can operate efficiently in their intended electromagnetic environment without causing or being susceptible to electromagnetic interference (EMI). Workbench troubleshooting is an essential skill for engineers and technicians to identify and resolve EMC issues during the development and testing phases of electronic products.

In this comprehensive guide, we will dive into the world of EMC and provide practical insights on how to effectively troubleshoot EMC problems from your workbench. We will cover the fundamentals of EMC, common EMC issues, diagnostic tools and techniques, and best practices for workbench troubleshooting.

Understanding the Basics of EMC

What is Electromagnetic Compatibility?

Electromagnetic compatibility (EMC) refers to the ability of electronic devices or systems to function satisfactorily in their electromagnetic environment without introducing intolerable electromagnetic disturbances to other devices in that environment. In simpler terms, EMC ensures that electronic devices can coexist and operate properly without causing or being affected by electromagnetic interference.

The Importance of EMC in Electronic Design

EMC is crucial in electronic design for several reasons:

- Reliability: EMC ensures that electronic devices function reliably and consistently in their intended electromagnetic environment.

- Safety: Proper EMC design prevents electromagnetic interference from causing malfunctions or safety hazards in electronic systems.

- Regulatory Compliance: Electronic products must meet EMC regulations and standards to be approved for sale in various markets worldwide.

- Customer Satisfaction: EMC-compliant devices provide a better user experience by minimizing interference and ensuring smooth operation.

Types of Electromagnetic Interference

Electromagnetic interference can be classified into two main categories:

- Conducted EMI: Interference that propagates through conductors, such as power lines, signal lines, or ground planes.

- Radiated EMI: Interference that propagates through the air as electromagnetic waves, such as radio frequency (RF) emissions.

Common EMC Issues and Their Causes

Conducted EMI Issues

- Power Line Noise: Noise or transients on power supply lines can cause conducted EMI issues.

- Ground Loops: Improper grounding or multiple ground paths can create ground loops, leading to conducted EMI problems.

- Cable Coupling: Unshielded or poorly shielded cables can pick up or radiate EMI, causing conducted interference.

Radiated EMI Issues

- Antenna Effects: Unintentional antennas, such as long PCB traces or cables, can radiate or receive EMI.

- Enclosure Leakage: Poorly designed or inadequately shielded enclosures can allow EMI to leak in or out.

- Harmonics and Spurious Emissions: Non-linear devices, such as switching power supplies or digital circuits, can generate harmonics and spurious emissions that cause radiated EMI.

Other EMC Issues

- Electrostatic Discharge (ESD): ESD events can cause damage or malfunctions in electronic devices.

- Transients and Surges: Voltage transients and surges can disrupt the operation of electronic systems or cause damage.

- Susceptibility: Electronic devices may be susceptible to external electromagnetic fields, leading to malfunctions or performance degradation.

Diagnostic Tools and Techniques for Workbench Troubleshooting

EMI Measurement Tools

- Spectrum Analyzers: Used to measure and visualize the frequency spectrum of EMI signals.

- Oscilloscopes: Help analyze time-domain waveforms and identify EMI issues.

- EMI Receivers: Specialized receivers designed for EMI measurements and compliance testing.

| Tool | Purpose |

|---|---|

| Spectrum Analyzer | Measures and visualizes the frequency spectrum of EMI signals |

| Oscilloscope | Analyzes time-domain waveforms and identifies EMI issues |

| EMI Receiver | Specialized receiver for EMI measurements and compliance testing |

Probing Techniques

- Near-Field Probes: Used to locate and measure local EMI sources on PCBs or components.

- Current Probes: Help measure conducted EMI currents in cables or traces.

- Voltage Probes: Used to measure EMI voltages on circuit nodes or power lines.

Shielding and Filtering Techniques

- Shielding Materials: Conductive materials, such as copper or aluminum, used to create EMI shields.

- Gaskets and Seals: Conductive gaskets and seals ensure proper shielding effectiveness at enclosure seams and openings.

- EMI Filters: Used to suppress conducted EMI on power lines or signal lines.

Grounding and Bonding Techniques

- Proper Grounding: Ensuring a low-impedance ground path and avoiding ground loops.

- Bonding: Connecting metal parts and enclosures to create a continuous EMI shield.

- Cable Shielding: Using shielded cables and properly terminating the shields to minimize EMI coupling.

Best Practices for Workbench Troubleshooting

Systematic Approach

- Problem Identification: Clearly define the EMC issue and its symptoms.

- Hypothesis Generation: Develop potential causes and solutions based on EMC principles and experience.

- Experimental Verification: Test the hypotheses using appropriate diagnostic tools and techniques.

Documentation and Record-Keeping

- Test Setup: Document the test setup, including equipment, settings, and configurations.

- Results and Observations: Record EMI measurements, waveforms, and observations during troubleshooting.

- Conclusions and Actions: Document the conclusions drawn from the troubleshooting process and the actions taken to resolve the EMC issue.

Collaboration and Knowledge Sharing

- Teamwork: Collaborate with colleagues and leverage their expertise in EMC Troubleshooting.

- Knowledge Sharing: Share experiences, best practices, and lessons learned with the team to build collective knowledge.

- Continuous Learning: Stay updated with the latest EMC techniques, standards, and industry practices through training and self-study.

Frequently Asked Questions (FAQ)

-

What is the difference between conducted EMI and radiated EMI?

Conducted EMI propagates through conductors, such as power lines or signal lines, while radiated EMI propagates through the air as electromagnetic waves. -

What are the common causes of conducted EMI issues?

Common causes of conducted EMI issues include power line noise, ground loops, and cable coupling. -

What tools are used for EMI measurements during workbench troubleshooting?

Spectrum analyzers, oscilloscopes, and EMI receivers are commonly used tools for EMI measurements during workbench troubleshooting. -

What are the benefits of using near-field probes in EMC troubleshooting?

Near-field probes help locate and measure local EMI sources on PCBs or components, allowing for targeted troubleshooting and EMI source identification. -

Why is proper grounding important for EMC?

Proper grounding provides a low-impedance path for EMI currents, minimizes ground loops, and ensures a stable reference for EMI measurements and troubleshooting.

Conclusion

Troubleshooting EMC issues from your workbench is a critical skill for engineers and technicians involved in electronic product development. By understanding the fundamentals of EMC, common EMC issues, and utilizing the right diagnostic tools and techniques, you can effectively identify and resolve EMC problems.

Remember to adopt a systematic approach, document your findings, and collaborate with your team to share knowledge and best practices. Continuous learning and staying updated with the latest EMC standards and techniques will enhance your troubleshooting abilities and contribute to the development of more reliable and EMC-compliant electronic devices.

By mastering the art of workbench troubleshooting for EMC, you can streamline the development process, ensure regulatory compliance, and deliver high-quality electronic products that meet the demands of today’s electromagnetic environment.

No responses yet