What is Flying Probe Test?

Flying probe test is an advanced method used in the printed circuit board assembly (PCBA) process to test the functionality and reliability of the assembled board. Unlike traditional bed-of-nails testing, which requires a custom-designed fixture for each unique PCB, flying probe test uses movable probes that can accurately test any point on the board without the need for a specific fixture.

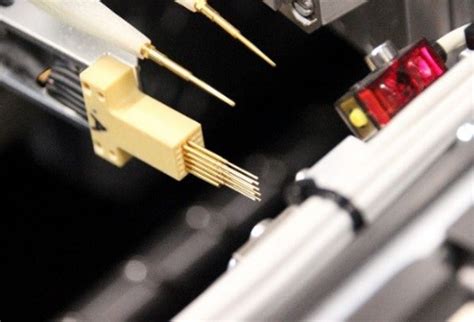

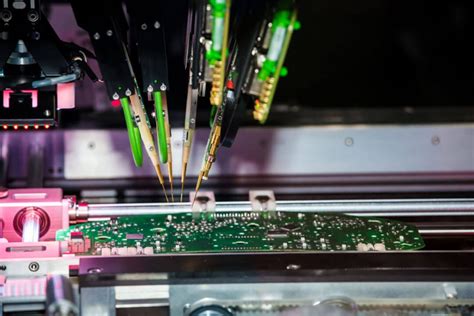

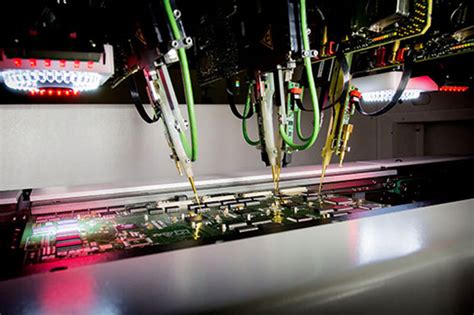

The flying probe tester consists of several key components:

- Precision XYZ positioning system

- Multiple probes (typically 4-8)

- High-resolution cameras for vision inspection

- Advanced software for test program creation and execution

During the testing process, the probes move across the surface of the PCB, making contact with the test points to perform electrical measurements such as continuity, resistance, capacitance, and voltage. The tester can also perform functional tests by simulating the operation of the assembled board.

Advantages of Flying Probe Test

Flying probe test offers several advantages over traditional bed-of-nails testing:

- Flexibility: Flying probe testers can easily adapt to changes in PCB design without requiring a new fixture.

- Cost-effective: Eliminating the need for custom fixtures reduces the overall cost of testing, especially for low-volume production runs or prototype testing.

- Improved test coverage: Flying probe testers can access test points that may be difficult or impossible to reach with a bed-of-nails fixture.

- Faster setup: Programming a flying probe tester is generally faster than designing and fabricating a custom bed-of-nails fixture.

Applications of Flying Probe Test in PCBA

Flying probe test is used in various stages of the PCBA process, including:

- Prototype testing: Flying probe test is ideal for testing prototype PCBs before mass production, as it allows for quick and efficient testing without the need for a custom fixture.

- Low-volume production: For low-volume production runs, flying probe test is often more cost-effective than investing in a custom bed-of-nails fixture.

- High-mix, low-volume manufacturing: In situations where a manufacturer produces a wide variety of PCBs in small quantities, flying probe test offers the flexibility needed to quickly adapt to different board designs.

- Rework and repair: Flying probe testers can be used to diagnose and troubleshoot issues on assembled boards, helping to identify the root cause of failures and guide the rework process.

Types of Tests Performed by Flying Probe Testers

Flying probe testers can perform a wide range of electrical tests, including:

- Continuity test: Verifies that all the connections on the PCB are intact and that there are no open circuits.

- Short circuit test: Checks for unintended connections between two or more points on the PCB.

- Resistance test: Measures the resistance between two points on the PCB to ensure that it falls within the specified tolerance.

- Capacitance test: Measures the capacitance of capacitors on the PCB to verify that they meet the required specifications.

- Diode test: Verifies the polarity and functionality of diodes on the PCB.

- Voltage test: Measures the voltage at various points on the PCB to ensure that it meets the specified requirements.

- Functional test: Simulates the operation of the assembled board to verify that it functions as intended.

Implementing Flying Probe Test in the PCBA Process

To successfully implement flying probe test in the PCBA process, consider the following steps:

- Design for testability: Ensure that the PCB design includes adequate test points and follows best practices for testability, such as providing clear markings for component orientation and test point locations.

- Generate test program: Create a comprehensive test program that includes all the necessary electrical tests and functional tests required to verify the functionality of the assembled board.

- Set up the tester: Configure the flying probe tester with the appropriate settings, such as probe type, contact force, and test speeds, based on the specific requirements of the PCB being tested.

- Perform the test: Execute the test program and monitor the results to identify any failures or anomalies.

- Analyze results: Review the test results and use them to guide any necessary rework or debugging efforts.

- Document and report: Maintain detailed records of the test results and generate reports to share with stakeholders and support continuous improvement efforts.

Best Practices for Flying Probe Test

To ensure the effectiveness and efficiency of flying probe test, consider the following best practices:

- Optimize test coverage: Strike a balance between test coverage and test time by focusing on the most critical test points and functions of the PCB.

- Minimize probe travel: Optimize the test program to minimize the distance the probes must travel between test points, reducing overall test time.

- Ensure probe tip maintenance: Regularly inspect and maintain the probe tips to ensure consistent contact and accurate measurements.

- Use appropriate fixtures: When necessary, use fixtures to secure the PCB during testing and provide additional test points for hard-to-reach areas.

- Continuously monitor and improve: Regularly review test results and process metrics to identify opportunities for improvement and optimize the overall efficiency of the flying probe test process.

Troubleshooting Common Issues in Flying Probe Test

Some common issues that may arise during flying probe test and their potential solutions include:

- Inconsistent contact: Ensure that the probe tips are clean and in good condition, and adjust the contact force if necessary.

- Inaccurate measurements: Verify that the tester is properly calibrated and that the test program is configured with the correct settings and tolerances.

- Damaged probes: Replace damaged probe tips promptly to avoid compromising test results.

- Slow test times: Optimize the test program to minimize probe travel and consider increasing test speeds if the PCB and components allow for it.

- False failures: Investigate the root cause of false failures, which may be due to incorrect test settings, inadequate test coverage, or issues with the PCB design itself.

Future Trends in Flying Probe Test

As PCBA technology continues to evolve, flying probe test is also expected to advance to keep pace with new challenges and requirements. Some future trends in flying probe test include:

- Increased speed and accuracy: Advancements in probe technology and positioning systems will enable faster and more accurate testing.

- Greater automation: Integration with automated handling systems and smart factories will streamline the flying probe test process and reduce human intervention.

- Adaptive testing: Intelligent algorithms will enable flying probe testers to dynamically adjust test parameters based on real-time results, optimizing test coverage and efficiency.

- Expanded test capabilities: Flying probe testers will continue to incorporate new test methods and measurements to accommodate the latest components and technologies used in PCBAs.

Conclusion

Flying probe test is a versatile and cost-effective method for testing PCBAs, offering flexibility, improved test coverage, and faster setup compared to traditional bed-of-nails testing. By understanding the principles of flying probe test, its applications, and best practices, PCBA manufacturers can effectively implement this testing method to ensure the quality and reliability of their products.

As technology advances, flying probe test will continue to evolve, providing even greater capabilities and efficiency in the PCBA Testing process. By staying informed about the latest trends and advancements in flying probe test, manufacturers can remain competitive and deliver high-quality products to their customers.

Frequently Asked Questions (FAQ)

-

What is the main difference between flying probe test and bed-of-nails testing?

Flying probe test uses movable probes to test any point on the PCB without requiring a custom fixture, while bed-of-nails testing relies on a fixed set of probes in a custom-designed fixture specific to each PCB design. -

Is flying probe test suitable for high-volume production?

While flying probe test is more commonly used for prototype testing and low-volume production, it can be used for high-volume production in certain situations. However, for very high-volume runs, bed-of-nails testing may be more efficient and cost-effective. -

Can flying probe testers perform functional tests?

Yes, flying probe testers can perform functional tests by simulating the operation of the assembled board and verifying that it functions as intended. -

How often should probe tips be inspected and maintained?

Probe tips should be regularly inspected and maintained to ensure consistent contact and accurate measurements. The frequency of maintenance depends on factors such as the type of PCBs being tested, the volume of testing, and the specific requirements of the tester manufacturer. -

What should be considered when designing a PCB for flying probe testability?

When designing a PCB for flying probe testability, consider including adequate test points, providing clear markings for component orientation and test point locations, and following best practices for layout and component placement to facilitate efficient testing.

No responses yet