What is Flying Probe Test?

Flying probe test is an advanced PCB testing method that uses movable probes to test the electrical connectivity and functionality of printed circuit boards (PCBs) without the need for a custom test fixture. This technology has revolutionized the PCB testing process, offering numerous advantages over traditional testing methods, such as increased flexibility, reduced setup time, and lower costs.

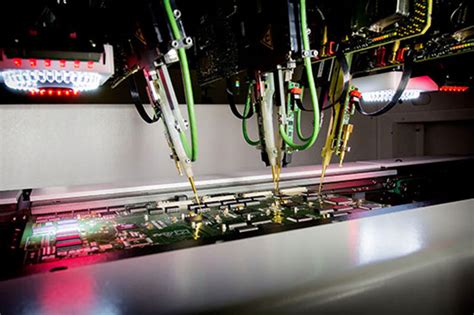

How Flying Probe Test Works

The flying probe test system consists of several key components:

- Movable probes: These probes are mounted on a high-precision XYZ positioning system that allows them to move freely across the surface of the PCB.

- Cameras: High-resolution cameras are used to accurately locate and align the probes with the test points on the PCB.

- Test electronics: The system includes advanced test electronics that can perform various measurements, such as continuity, resistance, capacitance, and voltage.

During the testing process, the system follows these steps:

- PCB loading: The PCB is loaded into the flying probe test machine, and the system aligns the board using fiducial marks or other reference points.

- Test program execution: The pre-programmed test sequence is executed, guiding the probes to the specified test points on the PCB.

- Probing and measurement: The probes contact the test points, and the test electronics perform the required measurements.

- Result analysis: The system compares the measured values with the expected values and generates a test report indicating pass/fail status and any detected faults.

Advantages of Flying Probe Test

Flying probe test offers several advantages over traditional PCB testing methods, such as in-circuit testing (ICT) and manufacturing defect analyzers (MDA):

- Flexibility: Flying probe test systems can easily adapt to different PCB designs and layouts without requiring custom test fixtures, making them ideal for low-volume production and prototyping.

- Reduced setup time: Since no custom test fixtures are needed, the setup time for flying probe testing is significantly shorter compared to other methods.

- Lower costs: The elimination of custom test fixtures reduces the overall cost of PCB testing, especially for low-volume production runs.

- Improved fault coverage: Flying probe test systems can access test points that may be difficult or impossible to reach with traditional test fixtures, resulting in better fault coverage.

- Rapid programming: Test programs for flying probe systems can be generated quickly from CAD data, reducing the time required to develop and debug test programs.

Applications of Flying Probe Test

Flying probe test is widely used in various stages of the PCB manufacturing process, including:

- Prototype testing: Flying probe test is an ideal solution for testing prototype PCBs, as it eliminates the need for expensive custom test fixtures and allows for quick validation of the design.

- Low-volume production: For low-volume production runs, flying probe test offers a cost-effective alternative to traditional testing methods, as it minimizes the investment in custom test fixtures.

- High-mix, low-volume manufacturing: In industries with a high mix of products and low production volumes, such as aerospace and defense, flying probe test provides the flexibility needed to efficiently test a wide range of PCB designs.

- Rework and repair: Flying probe test can be used to diagnose and troubleshoot faulty PCBs, helping to identify the root cause of failures and guide the rework and repair process.

Limitations of Flying Probe Test

While flying probe test offers numerous benefits, it does have some limitations:

- Test speed: Flying probe test is generally slower than traditional testing methods that use custom test fixtures, as the probes must move from one test point to another. However, advances in technology have significantly improved the speed of flying probe test systems in recent years.

- Limited access: In some cases, flying probe test may not be able to access certain test points due to physical obstacles or the close proximity of components on the PCB.

- Reduced test coverage: Flying probe test may not be able to perform certain types of tests, such as in-circuit component testing or functional testing, which can limit the overall test coverage compared to other methods.

Best Practices for Implementing Flying Probe Test

To ensure the success of flying probe test implementation, consider the following best practices:

- Design for testability: Incorporate testability features into the PCB design, such as test pads, vias, and clear labeling of components, to facilitate the flying probe testing process.

- Optimize test coverage: Carefully select the test points and measurements to maximize fault coverage while minimizing test time.

- Regularly calibrate the system: Ensure that the flying probe test system is regularly calibrated to maintain accuracy and repeatability of measurements.

- Develop comprehensive test programs: Create test programs that cover all critical aspects of the PCB, including continuity, resistance, capacitance, and voltage measurements.

- Integrate with other test methods: Use flying probe test in conjunction with other test methods, such as automated optical inspection (AOI) and boundary scan testing, to achieve a comprehensive test strategy.

Choosing the Right Flying Probe Test System

When selecting a flying probe test system for your PCBA needs, consider the following factors:

- Probe count: The number of probes available on the system determines the maximum number of simultaneous measurements that can be performed, which can impact test speed and coverage.

- Positioning accuracy: Higher positioning accuracy ensures more reliable contact with test points and reduces the risk of damage to the PCB or components.

- Test capabilities: Ensure that the system supports the required test types, such as continuity, resistance, capacitance, and voltage measurements.

- Software features: Look for a system with user-friendly software that offers features such as automatic test program generation, real-time result analysis, and comprehensive reporting.

- Support and training: Choose a supplier that provides comprehensive support and training to ensure the successful implementation and operation of the flying probe test system.

The Future of Flying Probe Test in PCBA

As the demand for high-quality, reliable PCBs continues to grow, the role of flying probe test in PCBA is expected to expand. Advances in technology, such as faster and more precise positioning systems, improved test electronics, and machine learning algorithms for data analysis, will further enhance the capabilities of flying probe test systems.

Moreover, the increasing complexity of PCB designs and the growing trend towards miniaturization will drive the adoption of flying probe test as a preferred testing method for many applications. The flexibility and adaptability of flying probe test make it well-suited to meet the evolving needs of the PCBA industry.

Frequently Asked Questions (FAQ)

-

Q: What is the main difference between flying probe test and in-circuit testing (ICT)?

A: The main difference is that flying probe test uses movable probes to test the PCB without requiring a custom test fixture, while ICT relies on a bed-of-nails fixture specific to each PCB design. -

Q: Can flying probe test completely replace other testing methods, such as ICT or functional testing?

A: While flying probe test offers many advantages, it may not be able to completely replace other testing methods. A comprehensive test strategy often involves using flying probe test in conjunction with other methods to achieve the desired test coverage and fault detection. -

Q: How long does it take to set up and program a flying probe test system for a new PCB design?

A: The setup and programming time for a flying probe test system is typically much shorter compared to methods that require custom test fixtures. However, the exact time can vary depending on the complexity of the PCB design and the specific requirements of the test program. -

Q: Is flying probe test suitable for high-volume production?

A: While flying probe test is often used for low-volume production and prototyping, advances in technology have made it increasingly viable for high-volume production as well. The decision to use flying probe test for high-volume production depends on factors such as the complexity of the PCB, the required test coverage, and the overall cost-benefit analysis. -

Q: What skills are required to operate a flying probe test system effectively?

A: Operating a flying probe test system requires a combination of technical skills and knowledge, including:- Understanding of PCB design and manufacturing processes

- Familiarity with test specifications and requirements

- Proficiency in using the flying probe test system software

- Ability to analyze test results and troubleshoot issues

- Knowledge of best practices for PCB testing and quality control

Proper training and support from the system supplier can help ensure that operators have the necessary skills to use the flying probe test system effectively.

| Comparison | Flying Probe Test | In-Circuit Testing (ICT) |

|---|---|---|

| Test Fixture Required | No | Yes |

| Setup Time | Short | Long |

| Adaptability to PCB Design | High | Low |

| Test Coverage | Good | Excellent |

| Test Speed | Slower | Faster |

| Cost for Low-Volume | Lower | Higher |

In conclusion, flying probe test has emerged as a powerful and versatile solution for PCB testing in the PCBA industry. Its flexibility, shorter setup times, and lower costs make it an attractive option for a wide range of applications, from prototype testing to low-volume production. As technology continues to advance, flying probe test is poised to play an increasingly important role in ensuring the quality and reliability of PCBs in the future.

No responses yet