Introduction to RAYPCB

RAYPCB is a leading PCB manufacturer based in China, known for its high-quality products and innovative solutions. As the first company to offer PCB fabrication with conformal coating in China, RAYPCB has set itself apart from its competitors and established a strong reputation in the industry.

What is conformal coating?

Conformal coating is a protective layer applied to PCBs to shield them from environmental factors such as moisture, dust, chemicals, and extreme temperatures. This coating helps to improve the reliability and longevity of the PCB, making it ideal for use in harsh environments or critical applications.

Benefits of conformal coating

- Protection against moisture and humidity

- Increased resistance to chemicals and solvents

- Improved insulation and reduced risk of short circuits

- Enhanced mechanical strength and durability

- Better performance in extreme temperature conditions

RAYPCB’s conformal coating services

RAYPCB offers a range of conformal coating options to suit the specific needs of its customers. The company’s experienced technicians use state-of-the-art equipment and high-quality materials to ensure that each PCB receives a uniform and reliable coating.

Conformal coating materials

RAYPCB uses a variety of conformal coating materials, including:

- Acrylic

- Polyurethane

- Silicone

- Epoxy

- Parylene

Each material has its own unique properties and benefits, and RAYPCB’s experts can help customers select the most suitable option for their specific application.

Application methods

RAYPCB employs several methods to apply conformal coating to PCBs, depending on the material used and the desired outcome. These methods include:

- Spray coating

- Brush coating

- Dip coating

- Vacuum deposition (for Parylene coating)

The company’s technicians are well-versed in each application method and can ensure that the coating is applied evenly and consistently across the entire PCB surface.

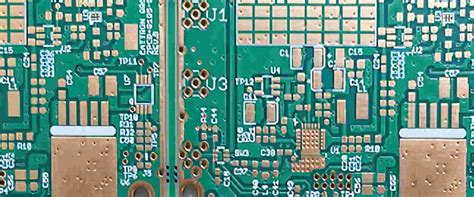

Quality control and testing

To guarantee the highest quality of its conformal coated PCBs, RAYPCB has implemented strict quality control measures and rigorous testing procedures.

Inspection and testing equipment

RAYPCB uses advanced inspection and testing equipment to verify the quality and performance of its conformal coated PCBs. This equipment includes:

- Automated optical inspection (AOI) machines

- X-ray inspection systems

- Thermal cycling chambers

- Salt spray chambers

- Humidity chambers

By utilizing these tools, RAYPCB can identify and address any issues or defects before the PCBs are shipped to customers.

Compliance with industry standards

RAYPCB’s conformal coating processes and materials comply with various industry standards, such as:

- IPC-CC-830: Qualification and Performance of Electrical Insulating Compound for Printed Wiring Assemblies

- MIL-I-46058C: Insulating Compound, Electrical (For Coating Printed Circuit Assemblies)

- IEC 61086-2: Coatings for loaded printed wire boards (conformal coatings) – Part 2: Requirements for coating materials

By adhering to these standards, RAYPCB ensures that its conformal coated PCBs meet the highest quality and reliability requirements.

Applications of conformal coated PCBs

Conformal coated PCBs are used in a wide range of industries and applications where reliability and durability are critical. Some common applications include:

- Automotive Electronics

- Aerospace and defense systems

- Medical devices

- Industrial control systems

- Consumer electronics exposed to harsh environments

Case studies

To illustrate the benefits of conformal coating, let’s take a look at a few case studies from RAYPCB’s clients:

Case study 1: Automotive electronics manufacturer

An automotive electronics manufacturer approached RAYPCB for help in improving the reliability of their PCBs used in engine control units (ECUs). These ECUs were exposed to high temperatures, vibrations, and moisture, which led to frequent failures and warranty claims.

RAYPCB recommended using a silicone conformal coating for the PCBs, as silicone offers excellent protection against high temperatures and moisture. After implementing the conformal coating, the manufacturer reported a significant reduction in ECU failures and warranty claims, resulting in cost savings and improved customer satisfaction.

Case study 2: Medical device company

A medical device company needed to ensure that their PCBs used in implantable devices could withstand the harsh environment of the human body. They required a biocompatible and highly reliable conformal coating solution.

RAYPCB suggested using Parylene conformal coating, as it is known for its excellent biocompatibility, moisture resistance, and pinhole-free coverage. The medical device company adopted Parylene coating for their PCBs and successfully passed all biocompatibility and reliability tests, enabling them to bring their innovative implantable devices to market.

Advantages of choosing RAYPCB for conformal coating

There are several reasons why customers should choose RAYPCB for their conformal coating needs:

- Extensive experience and expertise in PCB manufacturing and conformal coating

- Wide range of conformal coating materials and application methods

- Strict quality control measures and compliance with industry standards

- Competitive pricing and fast turnaround times

- Excellent customer support and communication throughout the project

FAQ

-

Q: What is the minimum order quantity (MOQ) for conformal coated PCBs at RAYPCB?

A: RAYPCB offers low MOQs for conformal coated PCBs, starting from just 5 pieces for prototype orders. -

Q: How long does it take to produce conformal coated PCBs at RAYPCB?

A: Lead times for conformal coated PCBs vary depending on the complexity of the design and the chosen coating material. Typically, RAYPCB can deliver conformal coated PCBs within 7-15 working days. -

Q: Can RAYPCB provide assistance in selecting the most suitable conformal coating material for my application?

A: Yes, RAYPCB’s experienced engineers can help customers choose the best conformal coating material based on their specific requirements, such as environmental conditions, performance needs, and budget. -

Q: Does RAYPCB offer masking services for areas that should not be coated?

A: Yes, RAYPCB provides masking services to protect connectors, switches, and other components that should not be coated. Customers can specify the areas to be masked in their design files or discuss their requirements with RAYPCB’s engineers. -

Q: Can RAYPCB provide certifications and test reports for conformal coated PCBs?

A: Yes, RAYPCB can provide various certifications and test reports for conformal coated PCBs, such as RoHS compliance, ISO 9001 certification, and conformal coating thickness and coverage test reports.

Conclusion

As the first PCB manufacturer to offer conformal coating services in China, RAYPCB has established itself as a leader in the industry. With its extensive experience, wide range of coating materials and application methods, strict quality control measures, and competitive pricing, RAYPCB is the ideal partner for customers seeking high-quality and reliable conformal coated PCBs.

By choosing RAYPCB for their conformal coating needs, customers can benefit from improved PCB durability, reliability, and performance in harsh environments, ultimately leading to cost savings and enhanced customer satisfaction.

For more information about RAYPCB’s conformal coating services and to request a quote, please visit www.raypcb.com or contact the company’s sales team at [email protected].

No responses yet