What is an Automated BOM?

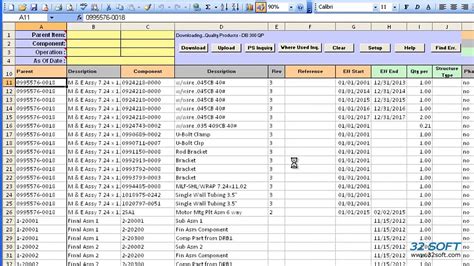

An automated BOM is a digital version of the traditional bill of materials that utilizes software to manage and maintain the list of components and materials required for a project. This software allows project managers to create, update, and share the BOM with all stakeholders in real-time, ensuring that everyone has access to the most up-to-date information.

Key Features of an Automated BOM

- Real-time updates

- Centralized database

- Integration with other project management tools

- Version control

- Access control and permissions

Benefits of an Automated BOM in Project Management

1. Improved Accuracy and Consistency

One of the primary benefits of an automated BOM is the improvement in accuracy and consistency it provides. By maintaining a centralized database of all components and materials, project managers can ensure that everyone is working with the same information, reducing the risk of errors and inconsistencies.

| Traditional BOM | Automated BOM |

|---|---|

| Manual updates | Real-time updates |

| Prone to errors | Improved accuracy |

| Inconsistent information | Consistent information across all stakeholders |

2. Enhanced Collaboration and Communication

An automated BOM enables better collaboration and communication among project team members, suppliers, and other stakeholders. With real-time access to the BOM, everyone can stay informed about the latest changes and updates, facilitating smoother coordination and decision-making.

3. Increased Efficiency and Productivity

By automating the BOM process, project managers can save significant time and effort that would otherwise be spent on manual updates and revisions. This increased efficiency allows teams to focus on more value-added tasks, ultimately leading to improved productivity and faster project completion.

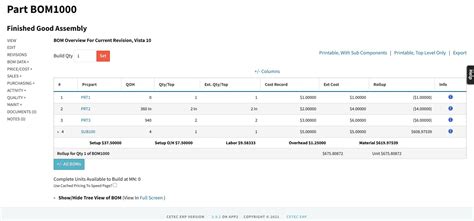

4. Better Inventory Management

An automated BOM helps project managers optimize inventory levels by providing accurate and up-to-date information on material requirements. This enables better planning and procurement decisions, reducing the risk of stockouts or overstocking, and ultimately leading to cost savings.

| Benefits of Automated BOM in Inventory Management |

|---|

| Accurate material requirements |

| Optimized inventory levels |

| Reduced risk of stockouts or overstocking |

| Cost savings through better planning and procurement |

5. Seamless Integration with Other Systems

Automated BOM software can often integrate with other project management tools, such as Enterprise Resource Planning (ERP) or Product Lifecycle Management (PLM) systems. This integration allows for seamless data exchange and ensures that all project-related information is kept in sync, further enhancing efficiency and accuracy.

6. Improved Change Management

Changes are inevitable in any project, and managing these changes effectively is crucial for success. An automated BOM simplifies the change management process by allowing project managers to easily update and track changes to the materials list, ensuring that all stakeholders are aware of the latest modifications.

7. Enhanced Traceability and Compliance

An automated BOM provides a complete audit trail of all changes and updates made to the materials list, enhancing traceability and making it easier to demonstrate compliance with industry regulations and standards. This is particularly important in industries such as aerospace, defense, and medical devices, where strict compliance requirements apply.

| Industry | Compliance Requirements |

|---|---|

| Aerospace | FAA regulations |

| Defense | MIL-STD, ITAR |

| Medical Devices | FDA regulations, ISO 13485 |

8. Faster Time-to-Market

By streamlining the BOM process and improving overall project efficiency, an automated BOM can help organizations bring their products or projects to market faster. This can provide a significant competitive advantage, particularly in industries where speed is critical.

9. Reduced Costs and Improved Profitability

Implementing an automated BOM can lead to significant cost savings by reducing errors, improving inventory management, and increasing overall efficiency. These cost savings, combined with faster time-to-market, can ultimately result in improved profitability for the organization.

10. Scalability and Future-Proofing

As organizations grow and projects become more complex, an automated BOM provides the scalability needed to accommodate these changes. By investing in an automated BOM solution, organizations can future-proof their project management processes, ensuring that they can adapt to evolving requirements and market demands.

Implementing an Automated BOM

While the benefits of an automated BOM are clear, implementing such a system requires careful planning and execution. Here are some key steps to consider when implementing an automated BOM:

- Assess your current BOM process and identify areas for improvement

- Define your requirements and select an appropriate automated BOM solution

- Integrate the automated BOM with your existing project management tools and processes

- Train your team on the new system and ensure buy-in from all stakeholders

- Continuously monitor and optimize your automated BOM process for maximum efficiency and effectiveness

Frequently Asked Questions (FAQ)

1. What is the difference between a traditional BOM and an automated BOM?

A traditional BOM is a static document that lists all the components and materials required for a project, while an automated BOM is a digital version that utilizes software to manage and maintain the list in real-time.

2. Can an automated BOM integrate with other project management tools?

Yes, many automated BOM solutions can integrate with other project management tools such as ERP or PLM systems, allowing for seamless data exchange and ensuring that all project-related information is kept in sync.

3. How does an automated BOM improve inventory management?

An automated BOM provides accurate and up-to-date information on material requirements, enabling better planning and procurement decisions. This helps optimize inventory levels, reduce the risk of stockouts or overstocking, and ultimately leads to cost savings.

4. Is an automated BOM suitable for all industries?

While an automated BOM can provide benefits to any industry, it is particularly valuable in industries with complex projects and strict compliance requirements, such as aerospace, defense, and medical devices.

5. How long does it take to implement an automated BOM?

The implementation timeline for an automated BOM varies depending on the size and complexity of the organization and its projects. However, with proper planning and execution, most organizations can successfully implement an automated BOM within a few weeks to a few months.

Conclusion

In conclusion, an automated BOM is a powerful tool that can provide numerous benefits to project managers and their teams. By improving accuracy, enhancing collaboration, increasing efficiency, and reducing costs, an automated BOM can help organizations streamline their project management processes and achieve better results. As the business landscape continues to evolve, investing in an automated BOM solution can provide a significant competitive advantage and ensure long-term success.

No responses yet