What are NTC Thermistors?

NTC thermistors, or Negative Temperature Coefficient thermistors, are temperature-sensitive resistors whose resistance decreases with increasing temperature. They are made from semiconductor materials, typically a mixture of metal oxides, such as manganese, nickel, cobalt, copper, and iron. The composition of these materials determines the specific characteristics of the thermistor.

The relationship between the resistance and temperature of an NTC thermistor is non-linear and can be described by the following equation:

R(T) = R0 * exp(B * (1/T – 1/T0))

Where:

– R(T) is the resistance at temperature T (in Kelvin)

– R0 is the resistance at a reference temperature T0 (usually 25°C or 298.15 K)

– B is the thermistor’s characteristic temperature coefficient (in Kelvin)

Characteristics of NTC Thermistors

NTC thermistors exhibit several key characteristics that make them suitable for temperature sensing applications:

-

High sensitivity: NTC thermistors have a high sensitivity to temperature changes, allowing for precise temperature measurements.

-

Wide temperature range: They can operate over a wide temperature range, typically from -50°C to 150°C, depending on the specific material composition.

-

Fast response time: NTC thermistors have a fast response time, enabling quick detection of temperature changes.

-

Small size: These sensors are available in small sizes, making them ideal for applications with space constraints.

-

Low cost: Compared to other temperature sensors, such as RTDs and thermocouples, NTC thermistors are relatively inexpensive.

Working Principle of NTC Thermistors

The working principle of NTC thermistors relies on the temperature-dependent behavior of semiconductor materials. As the temperature increases, the number of charge carriers (electrons and holes) in the semiconductor material increases, leading to a decrease in the material’s electrical resistance.

The relationship between the resistance and temperature of an NTC thermistor is non-linear, as described by the equation mentioned earlier. This non-linearity can be compensated for using various techniques, such as look-up tables or polynomial approximations.

NTC Thermistor Configurations

NTC thermistors are available in various configurations to suit different applications:

-

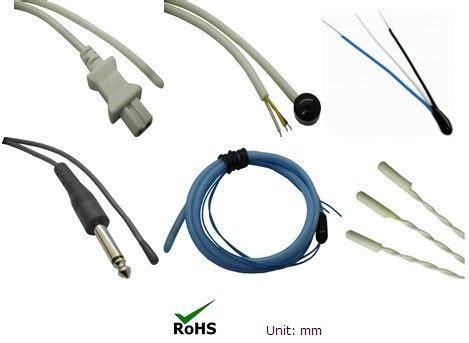

Bead thermistors: These are the most common type of NTC thermistors, consisting of a small bead of semiconductor material with two lead wires.

-

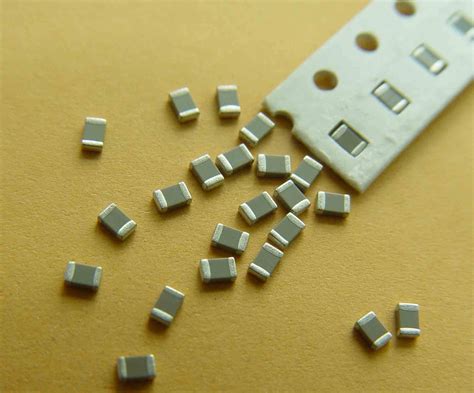

Surface-mount thermistors: Designed for surface-mount technology (SMT), these thermistors are suitable for automated assembly processes.

-

Probe thermistors: These thermistors are encased in a protective probe, making them suitable for immersion or air temperature measurements.

-

Chip thermistors: Chip thermistors are small, flat devices that can be easily integrated into printed circuit boards (PCBs).

Applications of NTC Thermistors

NTC thermistors find applications in a wide range of industries and products, including:

-

Consumer electronics: NTC thermistors are used in devices such as smartphones, laptops, and home appliances for temperature monitoring and control.

-

Automotive industry: These sensors are used in vehicle climate control systems, engine temperature monitoring, and battery management systems.

-

HVAC systems: NTC thermistors are employed in heating, ventilation, and air conditioning systems for temperature control and energy efficiency.

-

Medical devices: They are used in medical equipment, such as patient monitors, incubators, and thermal therapy devices.

-

Industrial process control: NTC thermistors are utilized in various industrial applications, including chemical processing, food and beverage manufacturing, and environmental monitoring.

Advantages of NTC Thermistors

NTC thermistors offer several advantages over other temperature sensing technologies:

-

High accuracy: NTC thermistors provide accurate temperature measurements, with typical accuracies ranging from ±0.1°C to ±0.5°C.

-

Excellent stability: These sensors exhibit excellent long-term stability, ensuring consistent performance over time.

-

Interchangeability: NTC thermistors are highly interchangeable, allowing for easy replacement without the need for recalibration.

-

Simple interface: The resistance output of NTC thermistors can be easily interfaced with electronic circuits using simple voltage divider or bridge configurations.

-

Ruggedness: NTC thermistors are rugged and can withstand harsh environments, including vibration and shock.

Disadvantages of NTC Thermistors

Despite their numerous advantages, NTC thermistors also have some limitations:

-

Non-linearity: The resistance-temperature relationship of NTC thermistors is non-linear, requiring additional compensation techniques for accurate temperature measurements.

-

Self-heating: When current passes through an NTC thermistor, it generates heat, which can affect the accuracy of the temperature measurement. This self-heating effect must be considered and minimized in the sensor design.

-

Limited temperature range: Compared to other temperature sensors, such as thermocouples, NTC thermistors have a relatively limited operating temperature range.

-

Fragility: Some NTC thermistor configurations, such as bead thermistors, are fragile and require careful handling to avoid damage.

Selecting the Right NTC Thermistor

When choosing an NTC thermistor for a specific application, several factors should be considered:

-

Temperature range: Ensure that the thermistor’s operating temperature range matches the application’s requirements.

-

Accuracy: Consider the required accuracy of the temperature measurement and select a thermistor with an appropriate tolerance.

-

Response time: Evaluate the desired response time of the temperature sensor and choose a thermistor configuration that meets those needs.

-

Environmental factors: Take into account the environmental conditions, such as humidity, vibration, and chemical exposure, and select a thermistor that can withstand those conditions.

-

Packaging: Choose a thermistor package that is compatible with the application’s mechanical and electrical requirements.

Interfacing NTC Thermistors with Electronic Circuits

NTC thermistors can be easily interfaced with electronic circuits using various methods:

-

Voltage divider: A simple voltage divider circuit can be used to convert the thermistor’s resistance change into a voltage output.

-

Wheatstone bridge: A Wheatstone bridge configuration can be employed to improve the accuracy and sensitivity of the temperature measurement.

-

Analog-to-digital conversion: The voltage output from the thermistor circuit can be converted into a digital value using an analog-to-digital converter (ADC) for further processing.

-

Signal conditioning: Additional signal conditioning circuitry, such as amplifiers and filters, can be used to improve the signal quality and reduce noise.

Calibration and Compensation Techniques

To ensure accurate temperature measurements, NTC thermistors often require calibration and compensation techniques:

-

Steinhart-Hart equation: This equation is a widely used method for approximating the non-linear resistance-temperature relationship of NTC thermistors.

-

Look-up tables: A look-up table containing pre-calculated resistance values corresponding to specific temperatures can be used for quick and accurate temperature conversion.

-

Polynomial approximation: A polynomial equation can be used to approximate the resistance-temperature curve of an NTC thermistor over a specific temperature range.

-

Self-heating compensation: Techniques such as pulsed current excitation or using a low-current source can be employed to minimize the self-heating effect of NTC thermistors.

Comparison with Other Temperature Sensors

NTC thermistors offer unique advantages and disadvantages compared to other common temperature sensors:

| Sensor Type | Advantages | Disadvantages |

|---|---|---|

| NTC Thermistor | High sensitivity, fast response, low cost | Non-linear, limited temperature range, self-heating |

| RTD | High accuracy, excellent stability, wide range | Expensive, slower response, fragile |

| Thermocouple | Wide temperature range, rugged, fast response | Lower accuracy, requires reference junction |

| Thermistor IC | Linear output, easy integration, digital interface | Limited temperature range, higher cost |

Future Trends in NTC Thermistor Technology

As technology advances, NTC thermistors continue to evolve to meet the demands of new applications:

-

Miniaturization: The development of smaller and more compact NTC thermistors enables their integration into increasingly miniaturized devices.

-

Improved performance: Ongoing research focuses on enhancing the accuracy, stability, and response time of NTC thermistors.

-

Wireless capabilities: The integration of NTC thermistors with wireless communication technologies allows for remote temperature monitoring and control.

-

Smart sensors: The combination of NTC thermistors with advanced signal processing and data analysis techniques enables the development of smart temperature sensors with enhanced functionality.

Frequently Asked Questions (FAQ)

- What is the main difference between NTC and PTC thermistors?

-

NTC thermistors have a negative temperature coefficient, meaning their resistance decreases with increasing temperature. PTC thermistors have a positive temperature coefficient, with their resistance increasing as temperature rises.

-

Can NTC thermistors be used for high-temperature applications?

-

While NTC thermistors are suitable for a wide range of temperatures, they are typically limited to operating temperatures below 150°C. For higher temperatures, other sensors like thermocouples or RTDs are more appropriate.

-

How does the self-heating effect impact NTC thermistor accuracy?

-

The self-heating effect occurs when current passing through the thermistor generates heat, causing a rise in its temperature. This can lead to inaccurate temperature measurements. To minimize this effect, low-current excitation or pulsed current techniques can be employed.

-

What is the typical response time of NTC thermistors?

-

The response time of NTC thermistors depends on factors such as the sensor size, packaging, and environment. Typically, bead thermistors have response times in the range of a few seconds, while surface-mount and chip thermistors can respond within a few milliseconds.

-

How do I select the right NTC thermistor for my application?

- When selecting an NTC thermistor, consider factors such as the required temperature range, accuracy, response time, environmental conditions, and packaging. Consult the manufacturer’s data sheets and application notes to ensure the chosen thermistor meets your specific requirements.

Conclusion

NTC thermistors are versatile and reliable temperature sensors that offer numerous advantages, including high sensitivity, fast response, and low cost. These sensors find applications in a wide range of industries, from consumer electronics to industrial process control. By understanding the working principles, characteristics, and interfacing techniques of NTC thermistors, designers can effectively integrate these sensors into their systems for accurate and efficient temperature measurement and control.

As technology continues to advance, NTC thermistors are expected to evolve, offering improved performance, miniaturization, and integration with wireless and smart sensing technologies. With their unique combination of benefits and ongoing development, NTC thermistors will remain a key component in temperature sensing applications for years to come.

No responses yet