Introduction to Temperature Sensor ICs

Temperature sensor ICs are integrated circuits designed to measure and monitor temperature in various applications. These sensors convert temperature into an electrical signal, which can be easily processed by other electronic components or microcontrollers. Temperature sensor ICs are widely used in industries such as automotive, aerospace, consumer electronics, and medical devices.

Types of Temperature Sensor ICs

There are several types of temperature sensor ICs available in the market, each with its own characteristics and advantages. Some of the most common types include:

-

Thermistor ICs: Thermistors are temperature-sensitive resistors that change their resistance based on temperature. Thermistor ICs integrate these resistors with signal conditioning circuitry to provide a linear output voltage or current proportional to the measured temperature.

-

Thermocouple ICs: Thermocouples are temperature sensors that consist of two dissimilar metals joined together at one end. When the junction is exposed to a temperature difference, it generates a voltage proportional to the temperature. Thermocouple ICs amplify and condition this voltage to provide a usable output signal.

-

Resistance Temperature Detector (RTD) ICs: RTDs are temperature sensors that change their resistance with temperature. They are known for their high accuracy and stability. RTD ICs incorporate these sensors along with signal conditioning and linearization circuitry to provide a precise temperature measurement.

-

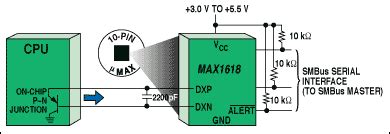

Semiconductor Temperature Sensor ICs: These ICs use the temperature-dependent properties of semiconductor materials, such as silicon, to measure temperature. They often integrate the sensor and signal conditioning circuitry on a single chip, making them compact and easy to use.

Analog Temperature Sensor ICs

Analog temperature sensor ICs provide an analog output signal, typically in the form of a voltage or current, that is proportional to the measured temperature. These ICs are suitable for applications that require continuous temperature monitoring and can interface directly with analog-to-digital converters (ADCs) or analog input pins of microcontrollers.

Advantages of Analog Temperature Sensor ICs

-

Simplicity: Analog temperature sensor ICs provide a straightforward way to measure temperature. The output signal can be easily read and processed by other electronic components without the need for complex digital interfaces.

-

Compatibility: Analog sensors are compatible with a wide range of ADCs and microcontrollers, making them suitable for integration into various systems.

-

Cost-effectiveness: Analog temperature sensor ICs are generally less expensive compared to their digital counterparts, making them a cost-effective solution for many applications.

Popular Analog Temperature Sensor ICs

Some popular analog temperature sensor ICs include:

-

LM35: The LM35 is a precision temperature sensor IC that provides an output voltage linearly proportional to the temperature in degrees Celsius. It has a wide operating range of -55°C to +150°C and does not require any external calibration.

-

TMP36: The TMP36 is a low-voltage, precision temperature sensor IC that provides an output voltage proportional to the temperature. It has a wide operating range of -40°C to +125°C and can be powered by a single supply voltage.

-

AD590: The AD590 is a two-terminal temperature sensor IC that provides a current output proportional to the absolute temperature. It has a wide operating range of -55°C to +150°C and exhibits excellent linearity.

-

MAX6605: The MAX6605 is a precision analog temperature sensor IC that provides a voltage output proportional to the temperature. It has a wide operating range of -55°C to +125°C and features high accuracy and low power consumption.

Interfacing Analog Temperature Sensor ICs

Interfacing analog temperature sensor ICs with microcontrollers or other electronic components involves reading the analog output signal and converting it into a usable temperature value. Here are the general steps for interfacing analog temperature sensor ICs:

-

Power Supply: Provide the necessary power supply to the temperature sensor IC as per its specifications. This typically involves connecting the positive supply voltage (Vcc) and ground (GND) pins to the appropriate power source.

-

Output Signal: Connect the output signal pin of the temperature sensor IC to an analog input pin of the microcontroller or ADC. This allows the microcontroller to read the analog voltage or current output of the sensor.

-

Analog-to-Digital Conversion: Use the ADC of the microcontroller to convert the analog output signal into a digital value. The resolution of the ADC determines the precision of the temperature measurement. Higher resolution ADCs provide more accurate readings.

-

Calibration and Conversion: Apply the necessary calibration and conversion factors to convert the digital value into a temperature reading. This typically involves using the sensor’s datasheet to determine the relationship between the output signal and the corresponding temperature.

-

Temperature Processing: Once the temperature value is obtained, it can be further processed, displayed, or used for controlling other components in the system.

Example: Interfacing LM35 with Arduino

Here’s an example of interfacing an LM35 temperature sensor IC with an Arduino microcontroller:

-

Connect the LM35’s Vcc pin to the Arduino’s 5V pin, and the GND pin to the Arduino’s GND pin.

-

Connect the LM35’s output pin to an analog input pin of the Arduino, such as A0.

-

In the Arduino sketch, read the analog value from the A0 pin using the

analogRead()function. -

Convert the analog value to voltage using the formula:

voltage = (analogValue / 1024.0) * 5.0. -

Convert the voltage to temperature in degrees Celsius using the formula:

temperature = voltage * 100.0. -

Display or process the temperature value as required.

Here’s a sample Arduino sketch:

void setup() {

Serial.begin(9600);

}

void loop() {

int analogValue = analogRead(A0);

float voltage = (analogValue / 1024.0) * 5.0;

float temperature = voltage * 100.0;

Serial.print("Temperature: ");

Serial.print(temperature);

Serial.println(" °C");

delay(1000);

}

Selecting the Right Analog Temperature Sensor IC

When choosing an analog temperature sensor IC for your project, consider the following factors:

-

Temperature Range: Ensure that the sensor’s operating temperature range covers the expected temperature range of your application.

-

Accuracy: Consider the accuracy requirements of your project. Some applications may require high precision, while others may tolerate a certain level of error.

-

Output Type: Determine whether a voltage or current output is more suitable for your system. Voltage output sensors are more common and easier to interface with, while current output sensors offer some advantages, such as better noise immunity.

-

Package and Size: Consider the physical dimensions and packaging of the sensor IC. Some applications may have size constraints or require a specific package type for ease of integration.

-

Price and Availability: Evaluate the cost and availability of the sensor IC. Choose a sensor that fits within your budget and is readily available from reliable suppliers.

Application Examples

Analog temperature sensor ICs find applications in various fields. Here are a few examples:

-

Environmental Monitoring: Analog temperature sensors can be used in weather stations, greenhouses, and agricultural monitoring systems to measure and record ambient temperature.

-

Industrial Process Control: In industrial settings, temperature sensors are used to monitor and control processes that require precise temperature regulation, such as chemical reactions, food processing, and manufacturing.

-

HVAC Systems: Analog temperature sensors are commonly used in heating, ventilation, and air conditioning (HVAC) systems to monitor and regulate the temperature of indoor spaces.

-

Automotive: Temperature sensors are used in various automotive applications, such as monitoring engine temperature, coolant temperature, and cabin temperature.

-

Consumer Electronics: Many consumer devices, such as thermostats, ovens, and refrigerators, use analog temperature sensors to monitor and control temperature.

Frequently Asked Questions (FAQ)

-

What is the difference between analog and digital temperature sensor ICs?

Analog temperature sensor ICs provide an analog output signal (voltage or current) that is proportional to the measured temperature. Digital temperature sensor ICs, on the other hand, provide a digital output, typically using protocols like I2C or SPI, which can be directly read by a microcontroller or processor. -

Can I use an analog temperature sensor IC with a 3.3V system?

Yes, many analog temperature sensor ICs are compatible with 3.3V systems. However, it’s important to check the sensor’s datasheet to ensure that it can operate with a 3.3V supply voltage and that the output signal is within the acceptable range for your system. -

How do I improve the accuracy of my temperature measurement?

To improve the accuracy of your temperature measurement, you can consider the following techniques: - Calibrate the sensor using known temperature references.

- Use a higher-resolution ADC to capture more precise readings.

- Implement signal filtering and averaging to reduce noise and fluctuations.

-

Ensure proper sensor placement and thermal coupling to the measured object or environment.

-

Can I use multiple analog temperature sensors with a single microcontroller?

Yes, you can use multiple analog temperature sensors with a single microcontroller by connecting each sensor’s output to a different analog input pin of the microcontroller. However, ensure that the microcontroller has enough analog input pins available and that the system can handle the processing and storage of multiple temperature readings. -

How do I protect the temperature sensor IC from harsh environments?

To protect the temperature sensor IC from harsh environments, consider the following measures: - Use a protective enclosure or coating to shield the sensor from moisture, dust, and other contaminants.

- Ensure proper electrical isolation and grounding to prevent electrical interference and damage.

- Use appropriate cable shielding and filtering to reduce electromagnetic interference (EMI) and noise.

- Select a sensor IC with a suitable operating temperature range and environmental specifications for your application.

Conclusion

Analog temperature sensor ICs provide a simple and cost-effective solution for measuring and monitoring temperature in various applications. By understanding the different types of analog temperature sensors, their characteristics, and interfacing techniques, you can effectively integrate them into your projects.

When selecting an analog temperature sensor IC, consider factors such as temperature range, accuracy, output type, package, and price. Proper interfacing and calibration techniques ensure accurate and reliable temperature measurements.

Analog temperature sensor ICs find applications in a wide range of fields, including environmental monitoring, industrial process control, HVAC systems, automotive, and consumer electronics. By leveraging these sensors, you can enhance the functionality and performance of your temperature-sensing projects.

No responses yet