Introduction to Taconic PCB

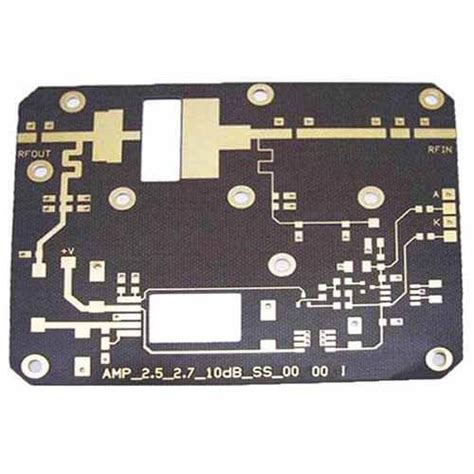

Taconic PCB, or printed circuit board, is a specialized type of PCB that utilizes Taconic laminate materials. These materials are known for their exceptional electrical properties, making them ideal for high-frequency and high-speed applications. Taconic PCBs are widely used in various industries, including telecommunications, aerospace, defense, and medical equipment manufacturing.

What Makes Taconic PCB Different?

Taconic PCBs stand out from traditional PCBs due to their unique laminate materials. Taconic laminates offer several advantages, such as:

- Low dielectric constant and dissipation factor

- Excellent thermal stability

- High mechanical strength

- Superior moisture resistance

These properties enable Taconic PCBs to deliver optimal performance in demanding environments and applications.

Taconic Laminate Materials

Taconic offers a wide range of laminate materials suitable for different applications. Some of the most popular Taconic laminates include:

RF-35

RF-35 is a low-loss, high-frequency laminate material that offers excellent electrical properties up to 35 GHz. It is well-suited for applications such as:

- Microwave and millimeter-wave circuits

- Antenna arrays

- Radar systems

TLY

TLY is a high-performance, low-loss material that provides stable electrical properties over a wide temperature range. It is commonly used in:

- Aerospace and defense applications

- Satellite communication systems

- High-speed digital circuits

TLX

TLX is a low-loss, high-frequency laminate that offers excellent thermal stability and low moisture absorption. It is ideal for:

- High-power RF amplifiers

- Phased array antennas

- Automotive radar systems

| Laminate | Dielectric Constant | Dissipation Factor | Thermal Stability | Moisture Resistance |

|---|---|---|---|---|

| RF-35 | 3.5 | 0.0037 | Excellent | Good |

| TLY | 2.2 | 0.0009 | Excellent | Excellent |

| TLX | 2.45 | 0.0019 | Excellent | Excellent |

Designing with Taconic PCB

When designing a Taconic PCB, several factors must be taken into consideration to ensure optimal performance and reliability.

Material Selection

Choosing the appropriate Taconic laminate material is crucial for meeting the specific requirements of your application. Consider factors such as:

- Frequency range

- Operating temperature

- Mechanical requirements

- Cost

Controlled Impedance

Controlled impedance is essential for maintaining signal integrity in high-speed circuits. Taconic PCBs offer excellent controlled impedance properties, ensuring reliable signal transmission.

Thermal Management

Proper thermal management is critical for preventing overheating and ensuring the longevity of your Taconic PCB. Consider incorporating features such as:

- Thermal vias

- Heat sinks

- Copper planes

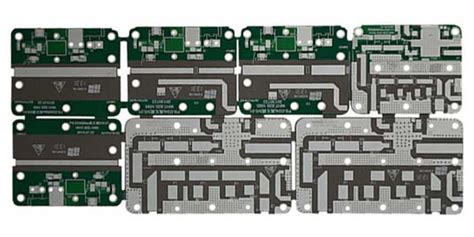

Manufacturing Considerations

When manufacturing Taconic PCBs, it is important to work with an experienced PCB fabricator who is familiar with handling Taconic laminates. Special attention should be given to:

- Drilling and routing parameters

- Copper plating processes

- Surface finish selection

Applications of Taconic PCB

Taconic PCBs find applications in various industries due to their superior electrical and mechanical properties.

Telecommunications

In the telecommunications industry, Taconic PCBs are used in:

- 5G infrastructure

- Base stations

- Microwave backhaul links

Aerospace and Defense

Taconic PCBs are well-suited for aerospace and defense applications, such as:

- Radar systems

- Satellite communication

- Avionics

Medical Equipment

Taconic PCBs are used in medical equipment that requires high-frequency performance and reliability, including:

- MRI scanners

- Ultrasound devices

- Wireless medical sensors

Automotive

In the automotive industry, Taconic PCBs are used in:

- Advanced driver assistance systems (ADAS)

- Automotive radar

- In-vehicle infotainment systems

Advantages of Using Taconic PCB

Taconic PCBs offer several advantages over traditional PCBs, making them the preferred choice for high-frequency and high-speed applications.

Improved Signal Integrity

The low dielectric constant and dissipation factor of Taconic laminates result in improved signal integrity, reducing signal loss and distortion.

Enhanced Reliability

Taconic PCBs demonstrate excellent thermal stability and moisture resistance, ensuring reliable performance in harsh environments.

Reduced Size and Weight

The superior electrical properties of Taconic laminates allow for the design of smaller and lighter PCBs, which is particularly beneficial in aerospace and portable applications.

Cost-effectiveness

Although Taconic laminates may have a higher initial cost compared to traditional materials, their superior performance and reliability can lead to cost savings in the long run by reducing maintenance and replacement costs.

Frequently Asked Questions (FAQ)

-

Q: What is the main difference between Taconic PCBs and traditional PCBs?

A: Taconic PCBs utilize specialized laminate materials that offer superior electrical properties, such as low dielectric constant and dissipation factor, making them ideal for high-frequency and high-speed applications. -

Q: Can Taconic PCBs be used for low-frequency applications?

A: While Taconic PCBs excel in high-frequency applications, they can also be used for low-frequency applications. However, the cost-benefit ratio may not be as favorable compared to using traditional PCB materials for low-frequency designs. -

Q: Are Taconic PCBs more expensive than traditional PCBs?

A: Yes, Taconic laminates typically have a higher initial cost compared to traditional PCB materials. However, the superior performance and reliability of Taconic PCBs can lead to long-term cost savings by reducing maintenance and replacement costs. -

Q: What are the main industries that use Taconic PCBs?

A: Taconic PCBs are widely used in industries such as telecommunications, aerospace, defense, medical equipment manufacturing, and automotive, where high-frequency performance and reliability are critical. -

Q: Can I manufacture Taconic PCBs using the same processes as traditional PCBs?

A: While many of the manufacturing processes are similar, working with Taconic laminates may require some specialized knowledge and experience. It is recommended to work with a PCB fabricator who has experience in handling Taconic materials to ensure the best results.

Conclusion

Taconic PCBs offer a superior solution for high-frequency and high-speed applications, thanks to their unique laminate materials and excellent electrical properties. When designing with Taconic PCBs, careful consideration must be given to material selection, controlled impedance, thermal management, and manufacturing processes. By leveraging the advantages of Taconic PCBs, designers can create reliable, high-performance electronic systems for a wide range of industries, including telecommunications, aerospace, defense, medical equipment, and automotive. As technology continues to advance, Taconic PCBs will likely play an increasingly important role in enabling the next generation of electronic devices and systems.

No responses yet