What is Stranded Wire?

Stranded wire consists of multiple thin copper strands twisted together to form a single conductor. The number of strands can vary depending on the wire gauge and intended application. Common strand counts include 7, 19, 26, and even higher numbers for thicker gauges.

The main advantages of stranded wire include:

- Flexibility: The multiple strands allow the wire to bend and flex more easily without breaking.

- Durability: Stranded wire is more resistant to fatigue and vibration, making it ideal for applications where the wire is subject to movement or stress.

- Reduced skin effect: At high frequencies, electrical current tends to flow along the outer surface of a conductor (known as the skin effect). Stranded wire has a larger surface area, which helps minimize the skin effect and maintain better signal integrity.

Common Applications for Stranded Wire

Stranded wire is commonly used in applications that require flexibility, such as:

- Automotive wiring

- Appliance cords

- Extension cords

- Headphone cables

- Robotic and machine wiring

- Audio and video cables

What is Solid Wire?

Solid wire consists of a single, solid copper conductor with no strands. It is typically more rigid and less flexible than stranded wire.

The main advantages of solid wire include:

- Lower cost: Solid wire is generally less expensive than stranded wire due to its simpler construction.

- Easier termination: Solid wire is easier to terminate in screw terminals or push-in connectors because it holds its shape better.

- Lower resistance: Solid wire typically has a lower electrical resistance compared to stranded wire of the same gauge, which can be beneficial for long runs or high-current applications.

Common Applications for Solid Wire

Solid wire is commonly used in applications that require a more permanent installation or where flexibility is not a primary concern, such as:

- Household wiring

- Electrical panel wiring

- Network cabling (e.g., Cat5, Cat6)

- Breadboarding and prototyping

- Low-voltage lighting systems

Comparing the Properties of Stranded and Solid Wire

To help you better understand the differences between stranded and solid wire, let’s compare their key properties:

| Property | Stranded Wire | Solid Wire |

|---|---|---|

| Flexibility | High | Low |

| Durability | High | Moderate |

| Resistance to Vibration | High | Low |

| Electrical Resistance | Slightly Higher | Lower |

| Cost | Higher | Lower |

| Termination Ease | Moderate | High |

| Skin Effect at High Frequencies | Lower | Higher |

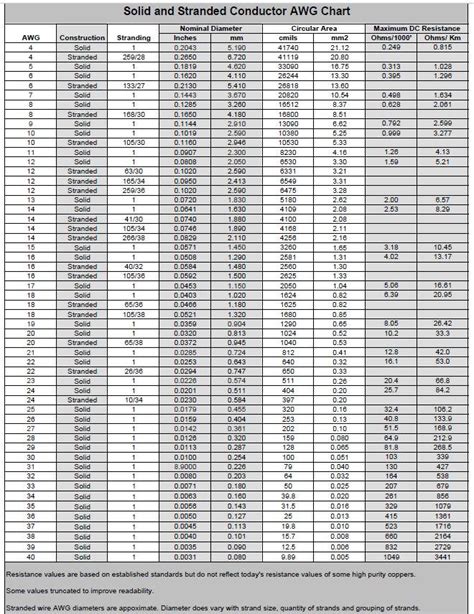

Wire Gauge and Ampacity

When selecting wire for your project, it’s essential to consider the wire gauge and its ampacity (current-carrying capacity). The wire gauge is a standardized measure of the wire’s diameter, with lower numbers indicating thicker wires and higher numbers indicating thinner wires.

The ampacity of a wire depends on several factors, including:

- Wire gauge

- Insulation type and temperature rating

- Ambient temperature

- Conductor material (copper or aluminum)

- Number of conductors in a cable or conduit

Here’s a table comparing the ampacity of stranded and solid copper wire for common gauges (based on the NEC):

| Wire Gauge (AWG) | Stranded Wire Ampacity (Amps) | Solid Wire Ampacity (Amps) |

|---|---|---|

| 14 | 20 | 20 |

| 12 | 25 | 25 |

| 10 | 30 | 30 |

| 8 | 40 | 40 |

| 6 | 55 | 55 |

Keep in mind that these ampacity values are for general reference and may vary depending on the specific application and environmental conditions. Always consult the National Electrical Code (NEC) or local regulations for the most accurate ampacity ratings and guidelines.

Choosing Between Stranded and Solid Wire

When deciding between stranded and solid wire for your project, consider the following factors:

- Application requirements: Determine whether your project requires flexibility, durability, or a more permanent installation.

- Environmental conditions: Consider the operating environment, including temperature, vibration, and moisture exposure.

- Signal integrity: For high-frequency or sensitive signal applications, stranded wire may be preferable due to its reduced skin effect.

- Termination methods: Think about how the wire will be terminated (e.g., screw terminals, soldering, or crimping) and choose the wire type that is easiest to work with.

- Cost: If cost is a primary concern and the application does not require the specific benefits of stranded wire, solid wire may be a more economical choice.

Frequently Asked Questions (FAQ)

1. Can I use stranded wire for household wiring?

While stranded wire can be used for household wiring, it is not the most common choice. Solid wire is typically preferred for permanent installations like household wiring because it is easier to terminate in screw terminals and maintains a more secure connection. However, if flexibility is a concern (e.g., in tight spaces or for short connections), stranded wire can be used as long as it meets the required ampacity and is properly terminated.

2. Is stranded wire more expensive than solid wire?

Yes, stranded wire is generally more expensive than solid wire due to its more complex construction and the additional manufacturing steps required to twist the strands together. However, the cost difference may be justified if the application requires the specific benefits of stranded wire, such as flexibility or resistance to vibration.

3. Can I mix stranded and solid wire in the same circuit?

While it is possible to mix stranded and solid wire in the same circuit, it is generally not recommended. Mixing wire types can lead to inconsistent electrical properties and may make terminations more difficult. It is best practice to use the same type of wire throughout a circuit to ensure optimal performance and easier maintenance.

4. What is the best way to terminate stranded wire?

The best way to terminate stranded wire depends on the application and the type of connector being used. Some common methods include:

- Soldering: Tinning the stranded wire ends before inserting them into a connector or soldering them directly to a board.

- Crimping: Using a specialized crimping tool and connectors designed for stranded wire.

- Screw terminals: Twisting the stranded wire ends tightly before inserting them into a screw terminal and ensuring the screw is properly tightened.

Always follow the manufacturer’s recommendations for the specific connectors or terminals you are using.

5. Can I use solid wire for automotive applications?

Solid wire is not recommended for automotive applications because it lacks the flexibility and resistance to vibration that stranded wire provides. The constant movement and vibration in vehicles can cause solid wire to fatigue and break over time, leading to electrical failures. Stranded wire is the preferred choice for automotive wiring harnesses and other vehicle electrical systems.

Conclusion

Choosing between stranded and solid wire ultimately depends on your specific application requirements, environmental conditions, and personal preferences. By understanding the key differences between these two types of copper conductors, you can make an informed decision that ensures optimal performance, reliability, and ease of installation for your electrical projects.

Remember to always follow the National Electrical Code (NEC), local regulations, and manufacturer guidelines when selecting and installing wire to ensure a safe and compliant electrical system.

No responses yet