Introduction

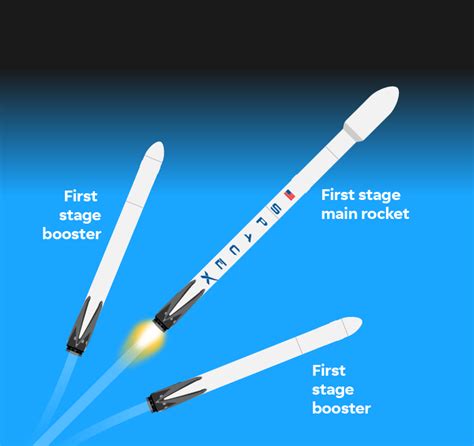

SpaceX, the pioneering space exploration company founded by Elon Musk, has achieved yet another milestone in its mission to revolutionize space travel. On [Insert Date], SpaceX successfully launched its Modular Falcon rocket, which incorporates reused engines from previous missions. This groundbreaking achievement marks a significant step forward in SpaceX’s efforts to reduce the cost of space launches and make space exploration more accessible.

The Modular Falcon Rocket

Design and Features

The Modular Falcon rocket is a testament to SpaceX’s innovative approach to rocket design. The rocket is built using a modular architecture, which allows for greater flexibility and adaptability in mission planning. The key features of the Modular Falcon include:

| Feature | Description |

|---|---|

| Reusable Engines | The Modular Falcon incorporates previously flown Merlin engines, reducing manufacturing costs and enabling rapid reusability. |

| Modular Design | The rocket’s modular structure allows for easy assembly, disassembly, and reconfiguration based on mission requirements. |

| Payload Capacity | The Modular Falcon can carry payloads of up to [Insert Payload Capacity] to low Earth orbit (LEO) and [Insert Payload Capacity] to geostationary transfer orbit (GTO). |

| Advanced Avionics | The rocket is equipped with state-of-the-art avionics and guidance systems, ensuring precise control and navigation during all stages of flight. |

Manufacturing Process

SpaceX has streamlined the manufacturing process for the Modular Falcon, leveraging advanced technologies and lean production methods. The company’s vertically integrated approach allows for greater control over the supply chain and enables rapid iteration and improvement.

The manufacturing process for the Modular Falcon includes:

-

Engine Production: The Merlin engines used in the Modular Falcon are manufactured in-house at SpaceX’s headquarters in Hawthorne, California. The engines undergo rigorous testing and quality control measures to ensure optimal performance.

-

Module Fabrication: The various modules that make up the Modular Falcon, such as the propellant tanks, payload fairing, and avionics bay, are fabricated using advanced composite materials and precision manufacturing techniques.

-

Assembly: The modules are then assembled into the complete Modular Falcon rocket at SpaceX’s facilities. The modular design allows for efficient assembly and reduces the time required for integration.

-

Testing: Before launch, the Modular Falcon undergoes extensive testing to validate its systems and ensure its readiness for flight. This includes static fire tests, where the engines are fired while the rocket is secured to the launch pad, as well as simulations and software checks.

The Launch

Pre-Launch Preparations

Leading up to the historic launch of the Modular Falcon, SpaceX conducted a series of pre-launch preparations to ensure the success of the mission. These preparations included:

-

Payload Integration: The payload, which included [Insert Payload Details], was carefully integrated into the Modular Falcon’s payload fairing. SpaceX worked closely with the payload customer to ensure proper integration and secure attachment.

-

Launch Pad Readiness: SpaceX’s launch pad at [Insert Launch Site] underwent thorough inspections and maintenance to ensure its readiness for the Modular Falcon launch. This included checks on the pad’s electrical systems, propellant storage tanks, and support structures.

-

Weather Monitoring: SpaceX’s meteorology team closely monitored weather conditions leading up to the launch to ensure favorable conditions for liftoff. The team assessed factors such as wind speed, cloud cover, and the presence of lightning to determine the optimal launch window.

-

Regulatory Approvals: Before the launch, SpaceX obtained all necessary regulatory approvals from relevant government agencies, such as the Federal Aviation Administration (FAA) and the National Oceanic and Atmospheric Administration (NOAA).

Launch Sequence

The launch of the Modular Falcon followed a carefully planned sequence to ensure a safe and successful liftoff. The key stages of the launch sequence included:

| Stage | Description |

|---|---|

| Ignition and Liftoff | The Merlin engines ignited, and the Modular Falcon lifted off from the launch pad, beginning its ascent. |

| Max Q | The rocket reached maximum dynamic pressure (Max Q), the point at which aerodynamic stress on the vehicle is highest. |

| Stage Separation | The first stage of the Modular Falcon separated from the second stage, allowing the second stage to continue its journey to orbit. |

| Second Stage Burn | The second stage engine ignited, propelling the payload towards its intended orbit. |

| Payload Deployment | Once the second stage reached the desired orbit, the payload was deployed from the Modular Falcon’s payload fairing. |

Throughout the launch sequence, SpaceX’s mission control center closely monitored the rocket’s performance, ensuring that all systems were functioning as intended.

Mission Success

The launch of the Modular Falcon was a resounding success, marking another significant achievement for SpaceX. The rocket performed flawlessly throughout the mission, and the payload was successfully deployed into its intended orbit.

The successful launch of the Modular Falcon demonstrates the viability of SpaceX’s approach to reusability and modular rocket design. By reusing previously flown engines and employing a modular architecture, SpaceX has shown that it is possible to reduce the cost of space launches while maintaining a high level of reliability and performance.

Impact and Future Prospects

Cost Reduction

One of the primary goals of SpaceX’s Modular Falcon program is to reduce the cost of space launches. By reusing engines and employing a modular design, SpaceX aims to significantly lower the price per launch, making space more accessible to a wider range of customers.

The cost reduction achieved by the Modular Falcon can be attributed to several factors:

-

Engine Reusability: By reusing previously flown Merlin engines, SpaceX eliminates the need to manufacture new engines for each launch, reducing production costs.

-

Modular Design: The modular architecture of the Modular Falcon allows for more efficient manufacturing and assembly processes, reducing the time and resources required to build each rocket.

-

Streamlined Operations: SpaceX’s vertically integrated approach and lean production methods enable more efficient operations, further reducing costs.

Increased Launch Frequency

The Modular Falcon’s reusable engines and modular design also enable SpaceX to increase its launch frequency. By reducing the time required to manufacture and assemble each rocket, SpaceX can launch more frequently, meeting the growing demand for access to space.

Increased launch frequency has several benefits:

-

Reduced Wait Times: Customers can have their payloads launched into orbit more quickly, reducing the time between mission planning and execution.

-

Improved Responsiveness: SpaceX can respond more rapidly to changing market demands and mission requirements, adapting its launch schedule as needed.

-

Greater Flexibility: The Modular Falcon’s modular design allows for greater flexibility in mission planning, enabling SpaceX to accommodate a wider range of payloads and orbital configurations.

Future Missions

The successful launch of the Modular Falcon opens up new opportunities for SpaceX and its customers. The rocket’s capabilities and cost-effectiveness make it an attractive option for a variety of missions, including:

-

Satellite Deployment: The Modular Falcon can be used to deploy a wide range of satellites, from small CubeSats to larger telecommunications and Earth observation satellites.

-

Space Station Resupply: The rocket can be used to deliver supplies and experiments to the International Space Station (ISS) and future commercial space stations.

-

Interplanetary Missions: The Modular Falcon’s modular design and reusable engines make it a viable option for future interplanetary missions, such as missions to the Moon and Mars.

SpaceX has already announced plans for future Modular Falcon launches, demonstrating the company’s confidence in the rocket’s capabilities and its commitment to advancing space exploration.

Frequently Asked Questions (FAQ)

-

Q: How does the Modular Falcon’s reusable engine technology work?

A: The Modular Falcon incorporates previously flown Merlin engines that have been refurbished and tested for reuse. After a mission, the engines are recovered, inspected, and undergo necessary maintenance before being integrated into a new Modular Falcon rocket for another launch. -

Q: What are the benefits of the Modular Falcon’s modular design?

A: The modular design of the Modular Falcon offers several benefits, including more efficient manufacturing and assembly processes, greater flexibility in mission planning, and the ability to accommodate a wider range of payloads and orbital configurations. -

Q: How does the Modular Falcon compare to other rockets in terms of payload capacity?

A: The Modular Falcon has a payload capacity of [Insert Payload Capacity] to low Earth orbit (LEO) and [Insert Payload Capacity] to geostationary transfer orbit (GTO). This makes it competitive with other rockets in its class, such as the [Insert Comparable Rocket]. -

Q: What measures does SpaceX take to ensure the reliability of reused engines?

A: SpaceX subjects reused engines to rigorous testing and quality control measures to ensure their reliability. This includes detailed inspections, performance tests, and flight readiness reviews. SpaceX has demonstrated the reliability of its reused engines through multiple successful launches. -

Q: How does the Modular Falcon contribute to SpaceX’s long-term goals?

A: The Modular Falcon is a key component of SpaceX’s long-term strategy to reduce the cost of space access and enable more frequent launches. By demonstrating the viability of reusable engines and modular rocket design, the Modular Falcon paves the way for future innovations and advancements in space exploration.

Conclusion

The successful launch of SpaceX’s Modular Falcon rocket with reused engines marks a significant milestone in the company’s pursuit of affordable and accessible space travel. By embracing reusability and modular design, SpaceX has demonstrated that it is possible to reduce the cost of space launches while maintaining a high level of performance and reliability.

The Modular Falcon’s success opens up new opportunities for SpaceX and its customers, enabling more frequent launches and a wider range of mission capabilities. As SpaceX continues to innovate and push the boundaries of space technology, the Modular Falcon will undoubtedly play a crucial role in the company’s future endeavors.

With its commitment to advancing space exploration and making it more accessible to all, SpaceX is poised to reshape the future of space travel. The launch of the Modular Falcon is just the beginning of an exciting new era in space exploration, one that promises to unlock new frontiers and expand our understanding of the universe.

No responses yet